INTRODUCTION

ALMATEC air-operated diaphragm pumps are constructed according to the state of the art and they are reliable.

Imminent danger by operating error or misuse can lead to damages of properties and/or persons. The pumps are to be

applied for the intended use and in a safety-related proper condition only.

Each person working on the ALMATEC air-operated diaphragm pumps concerning installation, start-up, handling or

maintenance has to read this manual completely and in an attentive way and has to follow all mentioned procedures

and safety notes.

GENERAL DESCRIPTION OF THE MACHINE, APPROPIATE USE AND RESIDUAL DANGERS

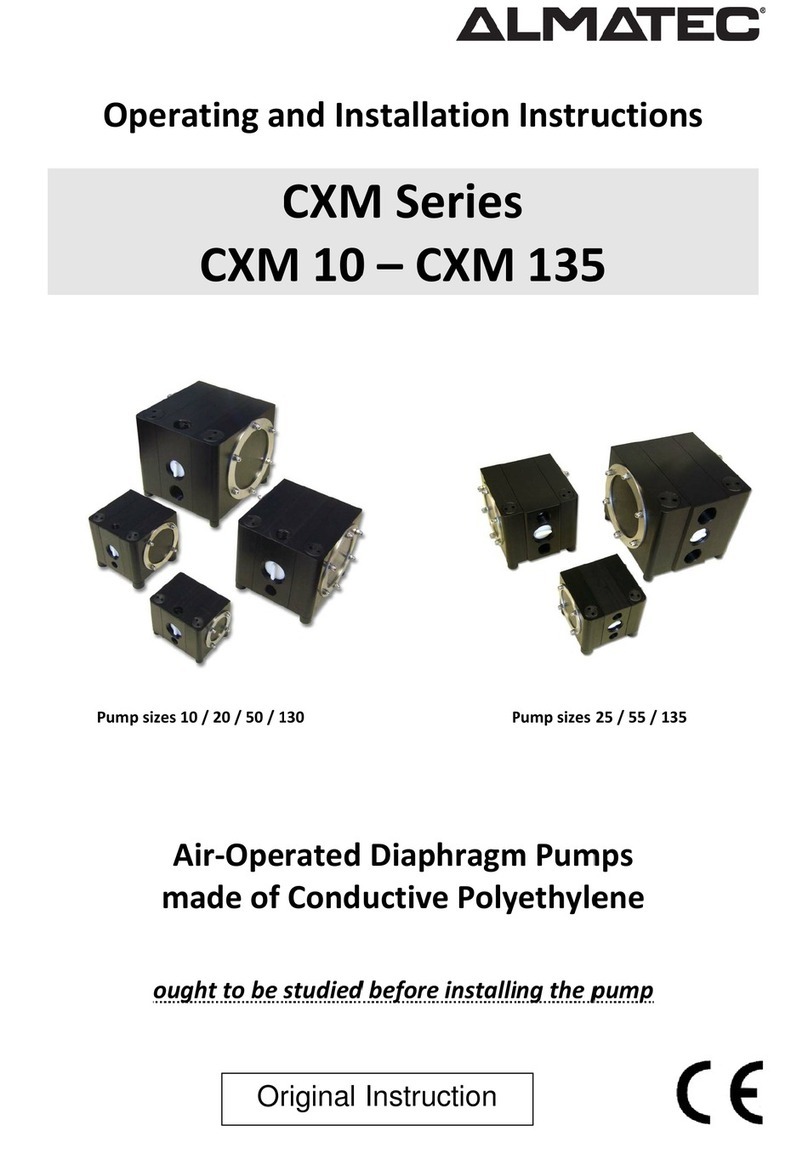

The ALMATEC CXM pumps are oscillating positive displacement pumps and are based

on the functional principle of double diaphragm pumps. The basic configuration

consists of two external side housings with a center housing between them. Each of the

side housings contains a product chamber which is sealed against the center housing

by a diaphragm. The two diaphragms are interconnected by a piston rod. Directed by

an air control system, the diaphragms are alternately loaded with compressed air so

that they move back and forth. In the first figure, the compressed air has forced the

left-hand diaphragm towards the product chamber and displaced the liquid from that

chamber through the open valve at the top to the discharge port. Liquid is

simultaneously drawn in by the right-hand diaphragm, thus refilling the second product

chamber. When the end of the stroke is reached, it reverses automatically, and the

cycle is repeated in the opposite direction. In the second figure, liquid is drawn in by

the left-hand diaphragm and displaced by the right-hand diaphragm.

The appropriate use of an Almatec air-operated diaphragm pump refers to the liquid transport taking into account the

operation parameter mentioned in this manual and in compliance of the given terms for commissioning, operation,

assembly, disassembly and maintenance.

Even if all necessary safety measures described in this manual have been met, a residual danger exists by leakages or

mechanical damages. At sealing areas or connections liquid can be released uncontrollably then.

STORAGE AND LONG-TERM USAGE

In general, the ALMATEC pump is delivered operational and packaged. If the unit is not installed right away, proper

storage conditions are important for a trouble-free operation later. The pump must be protected from wetness,

coldness, dirtying, UV-radiation and mechanical influences. The following storage conditions are recommended:

- Steady ventilated, dust and vibration free storage room

- Ambient temperature between 15°C and 25°C with a relative humidity below 65%

- Prevention of direct thermal influences (sun, heating)

Plastic materials are subject to aging processes depending on material, surrounding conditions and application

parameters. Chemical contact and/or increased temperature can amend material characteristics on the long run,

especially mechanical capabilities. For safety reasons, we do therefore recommend as part of every maintenance (resp.

in case of no maintenance till then after two years and then every six month): A careful visual check of all pump parts

for visible damages, a tactile check of all sealing surface (e.g. by moving a finger along the surface after cleaning), a

shape-check of the housing parts (e.g. by laying a drawer on plain surfaces) and a movability check of all threads. Any

eventually damaged part needs to be replaced!