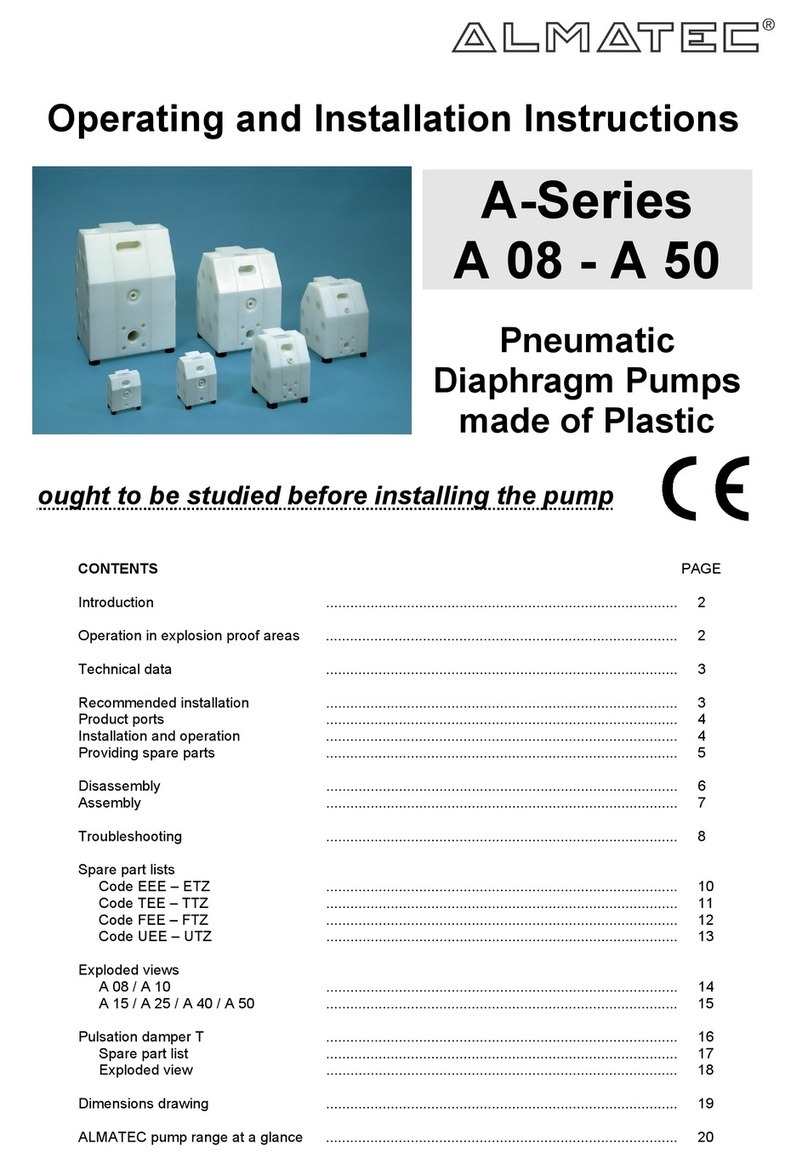

8

The air inlet [19] is located in the middle of the center housing [2]. Before installation, make sure that the air

supply pipe is free of solids. To supply the pump with driving air sufficiently, the pipe diameter should match

the size of the air inlet. Take care that no dirt or particles can intrude into the pump during the connection, as

these can accumulate inside the pump and can cause malfunctions. An air filter [24] directly behind the air inlet

[23] (not included in E 08 and E 10) prevents the entry of bulk particles.

The integrated air control system PERSWING P®[26] is a precision-control that requires oil-free, dry and clean

compressed air for optimal function. If humidity is expected, a water separator or air dryer has to be fitted to

protect the pump from blocking by ice. The ideal condition is the dewpoint of air at -20°C. In humid

surroundings, icing from the outside may occur despite the driving air is dried. If so, a prolonged waste-air-

exhaust (ca. 500 mm by pipe or hose) can be helpful. When installing the pump into boards or cabinets, it has

to be ensured that cold air does not get caught behind the muffler. In applications with a tendency to freezing

at the waste air exhaust, good experiences in practise have been achieved by pre-heating the driving air to

increase the distance to the dew point of the air. Doing so, it has to be considered that the driving air

temperature generally may not exceed 50°C to avoid expansion and sticking effects on the air side. This max.

air temperature is a well valid when using a compressor producing warm air which is e.g. often true for truck

compressors.

The pressure of the driving air should be limited to the amount required to meet the performance needed.

Excessive pressure increases both the air consumption and the wear of the pump. The pump is regulated by

tuning the flow rate of the air. For a proper operation at the lower performance range the regulation via a

needle valve is recommended. An empty pump has to be driven slowly (e.g. via a needle-valve). The pump

starts automatically. Pumps of the E-Series are self-priming when dry, thus it is not necessary to fill the suction

line of the pump. The suction lift capacity of a liquid-filled pump, however, is much higher. The pump is

appropriate for running dry during slow operation. Dry running at high stroke frequency causes premature

wear.The pumps can briefly (up to max. one hour) be operated against a closed discharge line. Throttling on

the suction side may damage the pump. When the pump operation has been stopped by a closed discharge,

the pressure equilibrium of the diaphragms must be ensured. This can be achieved by keeping the pump

connected to the air supply pressure; for longer stoppage, the pump must be released from the pressure within

the system on both fluid side and air supply side.

•Immediately before putting the pump into operation as well as after some hours of pumping,

the housing bolts [19] have to be fixed according to the torque data of the above schedule,

as the elements of construction "settle". The valve stops discharge valve [9] and the plugs

[11/13] have to be fixed too. Fixing all these parts is necessary as well after periods of

stoppage, at temperature variations, after transport and dismantling the pump.

•Installation, operation, and maintenance by qualified staff only.

•Pressure tests of the plant a pump is included in may only be carried out with the pump

disconnected from the pressure on both ports or by using the pressure the pump develops

while operating. The load of a pressure in the plant may damage the pump.

•Pump must not be operated with a positive suction pressure.

•Depending on the conditions of operation, the liquid conveyed might escape from the pump

through the muffler in case of a diaphragm rupture (in this case muffler has to be replaced).

For further safety requirements the optional equipment diaphragm monitoring and barrier

chamber system are recommended.

•In case of a diaphragm rupture, it might be possible fort he fluid pumped to intrude into the

air side of the pump. In very adverse conditions - e.g. pressure within the fluid system during

stopped air supply - the fluid might as well find its way into the air supply lines. To protect

other devices like pulsation dampers or even pneumatic valves, it is recommended to protect

the air supply line accordingly, e.g. via a non-return valve. This would as well avoid polluting

the air supply line.

•The state of the muffler has to be inspected regularly, as a blocked muffler can be forced out

of the pump. If this happens, damages of properties and/or persons cannot be excluded.

•If the product tends to settle, the pump has to be flushed regularly. For larger solids a filter

has to be installed in the suction line.

•In case of delivery of hot liquids the wetted pump must not standstill for a longer time,

Pump size E 08 E 10 E 15 E 25 E 40 E 50

Torque values for housing bolts (Nm):

PE pumps

PTFEpumps

-

2

-

4,5

8,5

6,5

14

11

18

15

23

19