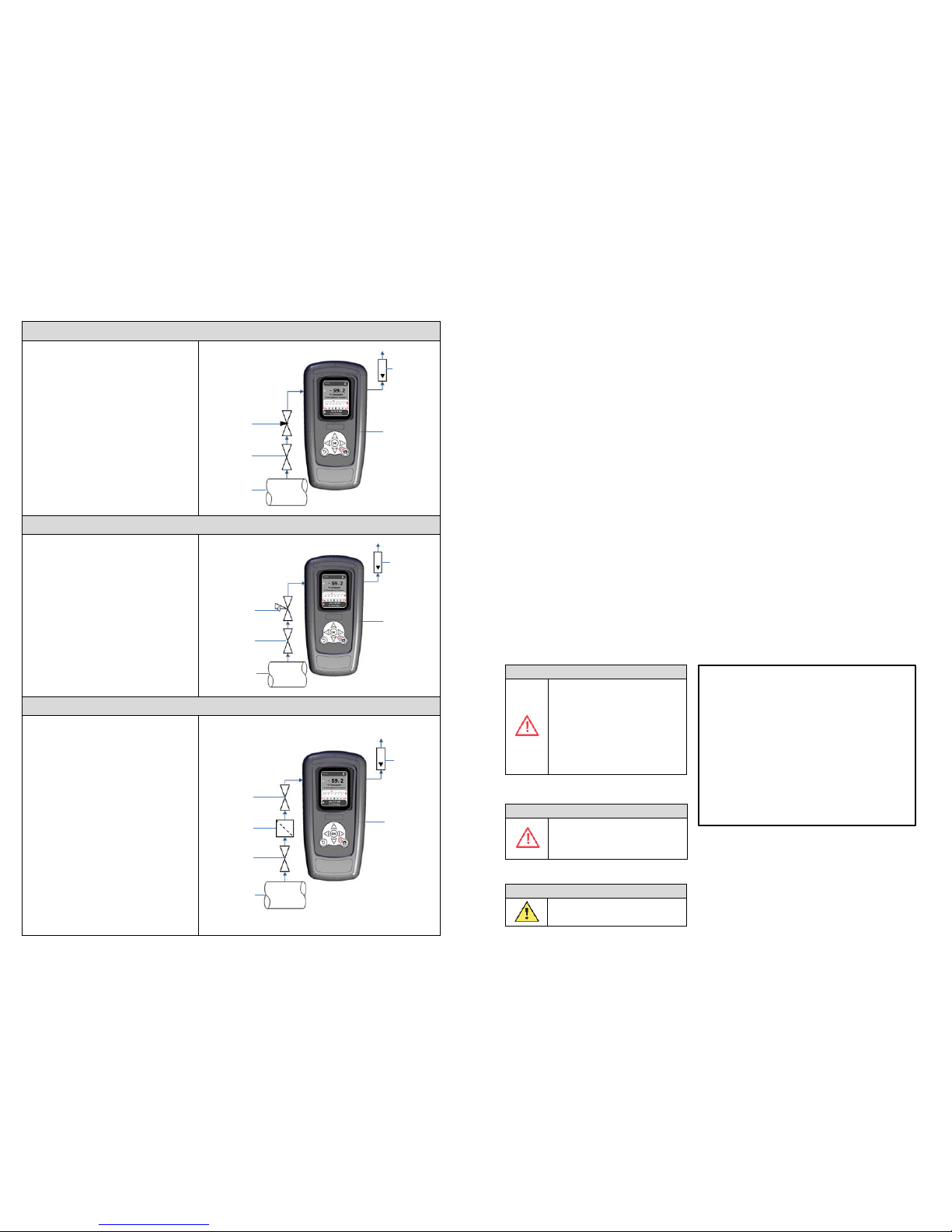

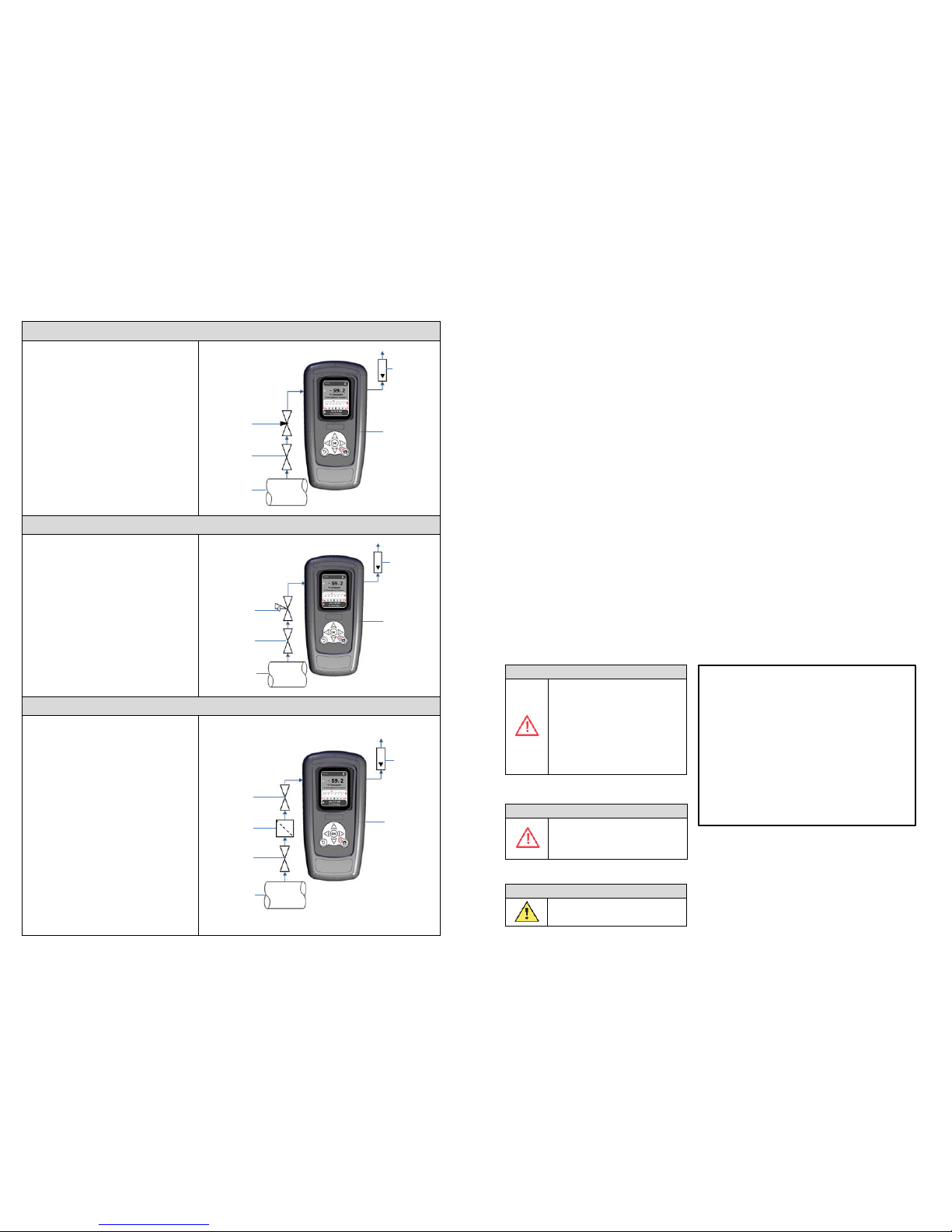

Reduce positive pressure gas

to atmospheric pressure.

Use a needle valve at low

pressures (<10 barg) to control

flow and pressure drop.

Reduce positive pressure gas to

atmospheric pressure.

Use a stainless steel, low swept

volume pressure regulator at higher

pressures (>10 barg).

Gases with Particulate/ Liquid Contamination

Filter all particulate matter. Use

a coalescing filter (with drain)

for heavy hydrocarbon

condensate samples.

Hygroscopic particulate

(desiccant dust) must achieve

moisture concentration

equilibrium which may cause a

buffering effect and delay the

sample result. Hygroscopic

liquid (glycol) may accentuate

the buffering effect (as above)

and render the sensor too slow

to use.

Install the filter as close to the

sample point as practical

1. Install the sample piping system and equipment as per the required installation configuration.

NOTE: The SADPmini2 is not connected to the inlet piping system at this stage.

2. Open the sample Isolation Valve and adjust the needle valve/ regulator to allow a flow of 5-15 litres per

minute to atmosphere through to sample pipe.

3. Allow the gas to flow through the sample pipe for 2 minutes to purge the system.

4. After ensuring that the sample gas is clean and dry connect the sample pipe to the instrument.

NOTE: The orientation of the ports is not important.

5. When the sample flow is low or very dry gas is being measured connect a >20 cm pipe to the outlet port

to prevent back diffusion.

6. Allow the gas to flow through the SADPmini2 for two minutes.

7. Press the power button on the SADPmini2 and ensure that the sensor is ‘dry’.

8. Block the instrument outlet, e.g. cover with a finger and allow the Desiccant Head to extend fully.

NOTE: Do not lift the Desiccant Head manually as this will draw ambient air into the sample chamber and

produce a false reading.

9. Unblock the outlet and allow the gas to flow through the sensor.

10. The displayed reading will rise until the sensor is in equilibrium with the sample gas.

11. When the displayed reading has settled record the final reading.

12. When completed manually depress the Desiccant Head fully.

NOTE: It is important to make sure the Desiccant Head is depressed fully when the equipment is not in

use to prevent the sensor and desiccant material becoming saturated.

13. Close the sample Isolation Valve.

14. Press and hold the power button for two seconds to switch off the SADPmini2.

15. Disconnect the pipework from the SADPmini2.

Do not expose the sensor to

NH3, Hg, CO or acid gases, such

as Cl2and HCI, as they

chemically attack the sensor

and destroy it. Strong oxidizing

agents such as O3should also

be avoided

Do not allow the pressure in

the instrument to exceed 0.3

barg/ 4 psi

Do not exceed a flow rate

of 20 litres per minute

Navigation Keys allow the user to access and

change the following:

•Time and Date settings

•International settings

•Dewpoint and concentration units

•Power saving options

See the user manual for details

Flow

Indicator

(optional)

Flow

Indicator

(optional)

Flow

Indicator

(optional)