Contents

1. Preliminary operations .......................................................................................................................................... 7

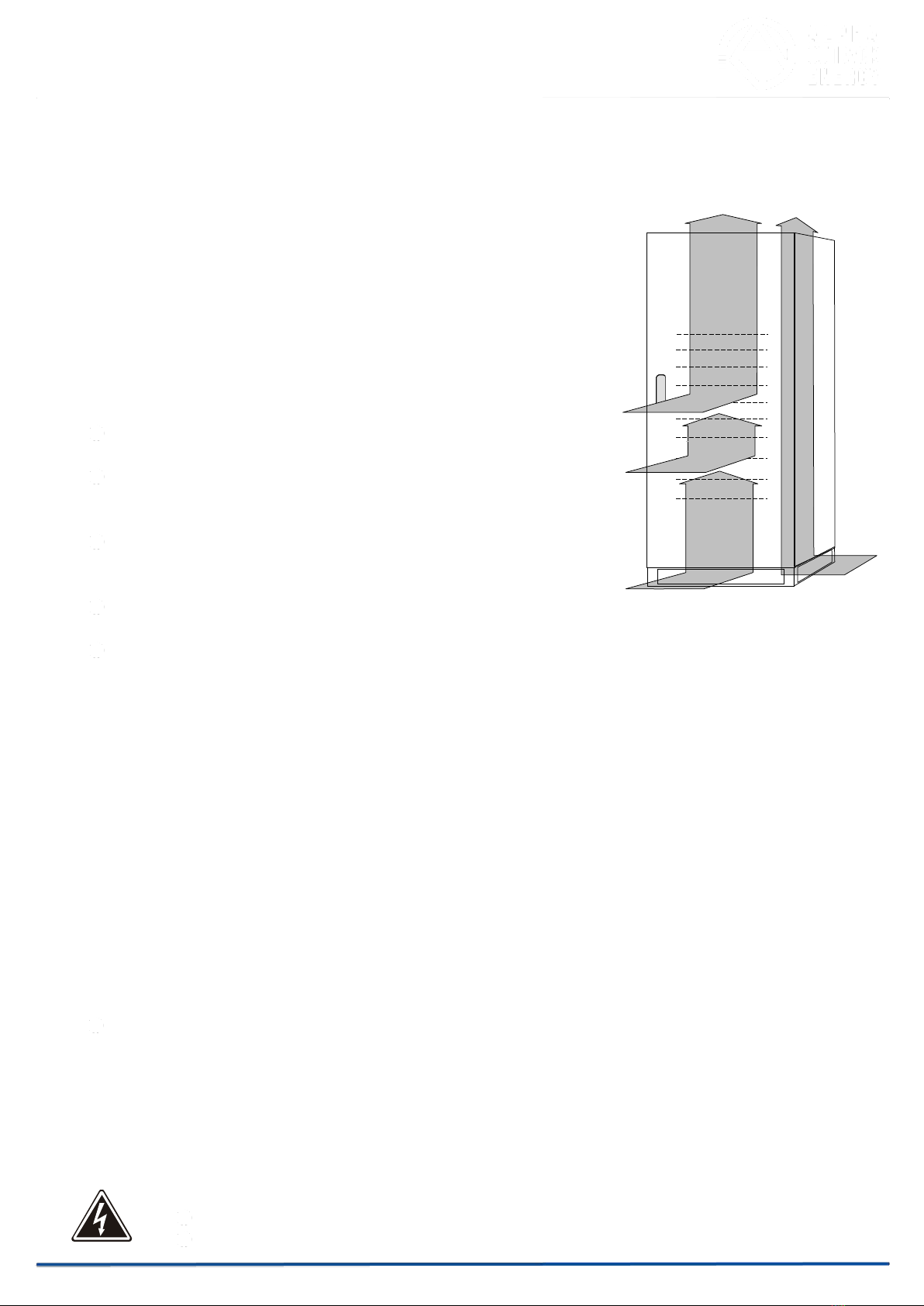

1.1 Removing the packaging and positioning the device ......................................................................................... 7

1.2 Storage ............................................................................................................................................................... 7

1.3 Handling.............................................................................................................................................................. 7

2. Installation environment ....................................................................................................................................... 8

2.1 Ambient conditions: ............................................................................................................................................ 8

2.2 Dimensions of the premises ............................................................................................................................... 8

2.3 Cooling of the premises ...................................................................................................................................... 9

2.4 Air change for battery premises ......................................................................................................................... 9

3. TRI POWER X33 HIP IN SINGLE CONFIGURATION ......................................................................................... 10

3.1 Set-up of the electrical system ......................................................................................................................... 10

3.1.1

Input ............................................................................................................................................................... 10

3.1.2

Selectivity ....................................................................................................................................................... 11

3.1.3

Battery ............................................................................................................................................................ 12

3.1.4

neutral conductor ........................................................................................................................................... 12

3.1.5

Differential (RCD) ........................................................................................................................................... 13

3.1.6

Backfeed protection ....................................................................................................................................... 14

3.1.7

Emergency power off device (EPO) .............................................................................................................. 14

3.2 Mains, load and battery connections ................................................................................................................ 15

3.3 Connection of signals and remote commands ................................................................................................. 17

3.3.1

EPO connector (emergency power off control).............................................................................................. 17

3.3.2

REMOTE COMMANDS AND ALARMS ......................................................................................................... 17

3.3.3

RS232 ............................................................................................................................................................ 18

3.3.4

Parallel (optional) ........................................................................................................................................... 19

3.3.5

SLOTS 2-1 ..................................................................................................................................................... 19

3.3.6

REMOTE ALARMS (2 optional cards) ........................................................................................................... 19

3.3.7

MODEM (optional) ......................................................................................................................................... 19

3.3.8

MULTI I / O (optional) .................................................................................................................................. 20

3.3.9

REMOTE PANEL (OPTIONAL) ..................................................................................................................... 20

3.3.10

Dual Bus System – UGS (optional). .............................................................................................................. 20

3.3.11

SWOUT and SWMB aux - External temperature sensor (optional). .............................................................. 21

3.4 Start-up procedure ............................................................................................................................................ 24

3.4.1

Battery operation check ................................................................................................................................. 25

3.5 Operating modes .............................................................................................................................................. 26

3.5.1

On - line - factory setting ................................................................................................................................ 26

3.5.2

Standby-on / Smart active .............................................................................................................................. 26

3.5.3

Standby-off (with mains present the load is not powered) ............................................................................. 27

3.5.4

Stabilizer (operation in on-line mode without battery) ................................................................................... 27

3.5.5

Frequency converter (from 50 to 60Hz or vice versa) ................................................................................... 27

3.6 Personalizations ............................................................................................................................................... 28

3.7 Procedure to transfer the load from UPS onto maintenance bypass. .............................................................. 28

3.8 UPS and load shutdown ................................................................................................................................... 29

3.9 Block diagram ................................................................................................................................................... 30

3.10 Components of the block diagrams .................................................................................................................. 31

4. TRI POWER X33 HIP IN PARALLEL CONFIGURATION ................................................................................... 34

4.1 Introduction ....................................................................................................................................................... 34

4.2 Electrical system set-up .................................................................................................................................... 35

4.2.1

Input ............................................................................................................................................................... 35

4.2.2

Differential ...................................................................................................................................................... 35

4.2.3

Emergency power off device (EPO) .............................................................................................................. 35

4.2.4

External maintenance bypass ........................................................................................................................ 36

Page 5 to 54