CONTENT

1. INTRODUCTION AND DESCRIPTION.................................. - 2 -

2. PREPARATION .................................................................. - 3 -

2.1. ATTACHING TO THE LATHE ...............................................- 3-

2.2. TOOLS ATTACHEMENT ....................................................- 4-

2.3. ATTACHING OF PRESSURE AIR AND COOLING FLUID .................- 6-

2.4. MANUAL TOOL POSITIONING ............................................- 9-

3. AUTOMATIC CONTROL................................................... - 10 -

3.1. WIRING CONNECTIONS .................................................- 10 -

3.2. SOFTWARE PRAPARATION ..............................................- 12 -

3.3. CONTROL MACROS ......................................................- 14 -

3.4. COOLANT CONTROL .....................................................- 15 -

3.5. OPERATION ON CNC LATHE ...........................................- 16 -

3.6. RUNNING THE PROGRAM FOR THE FIRST TIME .....................- 17 -

4. MAINTENANCE INSTRUCTIONS ...................................... - 18 -

4.1. LUBRICATION .............................................................- 18 -

4.2. CLEANING .................................................................- 18 -

5. TROUBLESHOOTING....................................................... - 19 -

5.1. ERRORS ....................................................................- 19 -

5.2. AFTER TURNING,THE HEAD DOES NOT RETRACT...................- 21 -

5.3. IMPAIRED MACHINING ACCURACY ....................................- 21 -

5.4. COOLANT SUPPLY IS INTERRUPTED ...................................- 21 -

5.5. THE HEAD EXTENDS BUT DOES NOT ROTATE ........................- 21 -

6. TECHNIC DATA ............................................................... - 24 -

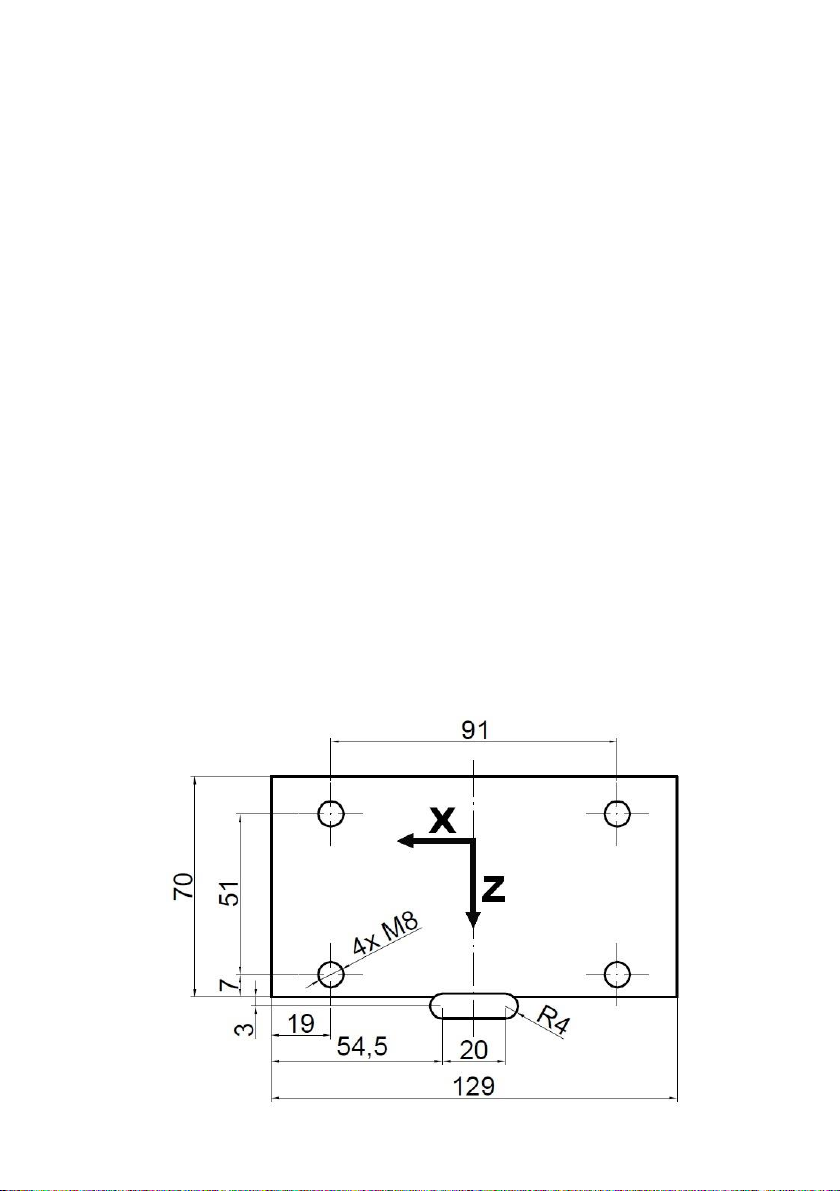

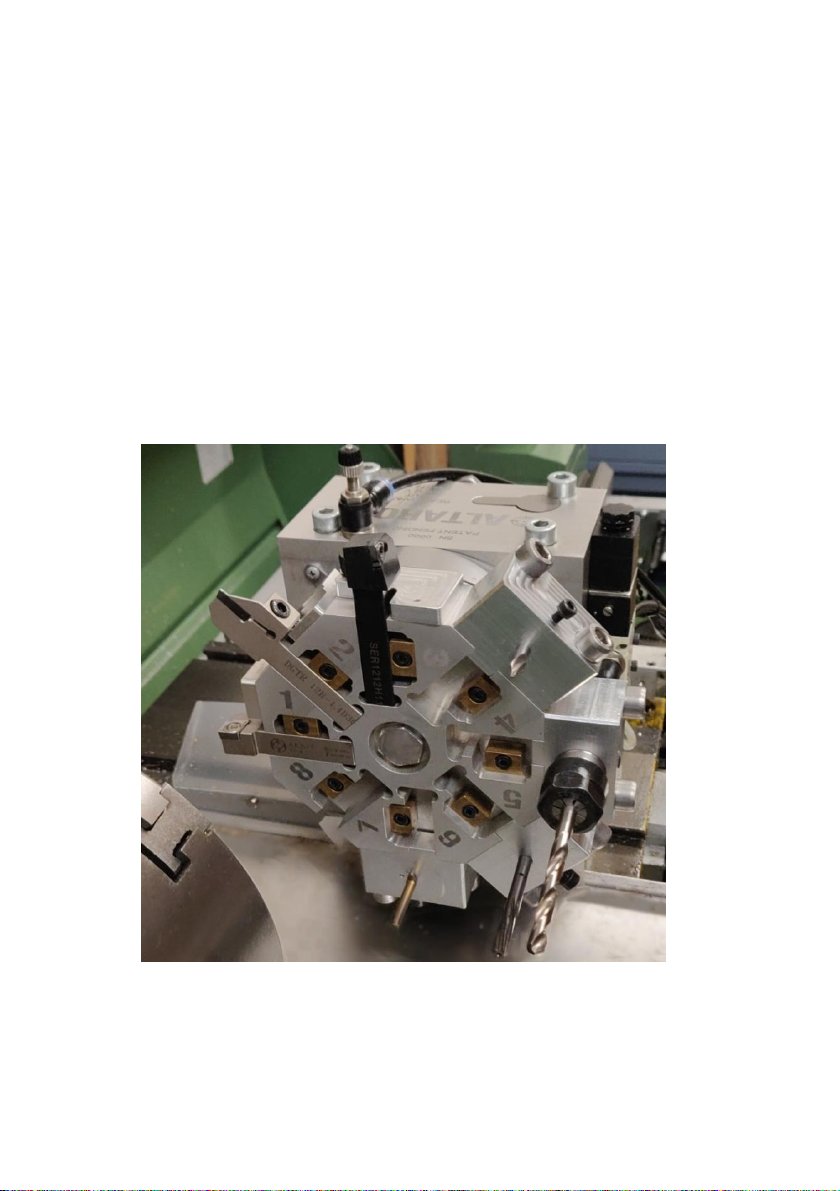

7. DRAWINGS..................................................................... - 25 -

7.1. TOOL CUBE................................................................- 25 -

7.2. COOLANT PLATE ..........................................................- 26 -

8. WARRANTY CONDITIONS ............................................... - 27 -