Table of Contents

Important Safety Instructions..............................................................................................................2

Safety Instructions................................................................................................................................................ 2

Radio Interference Statement.............................................................................................................................. 3

Symbols replace words on the equipment, on a display,.....................................................................................4

or in manuals.........................................................................................................................................................4

APsystems Microinverter System Introduction.................................................................................. 5

APsystems Microinverter YC500I Introduction...................................................................................7

APsystems Microinverter System Installation.................................................................................... 8

Additional Installation components from APsystems..........................................................................................8

Required Parts and Tools from you...................................................................................................................... 8

Installation Procedures......................................................................................................................................... 9

Step 1 - Position the AC bus cable................................................................................................................ 9

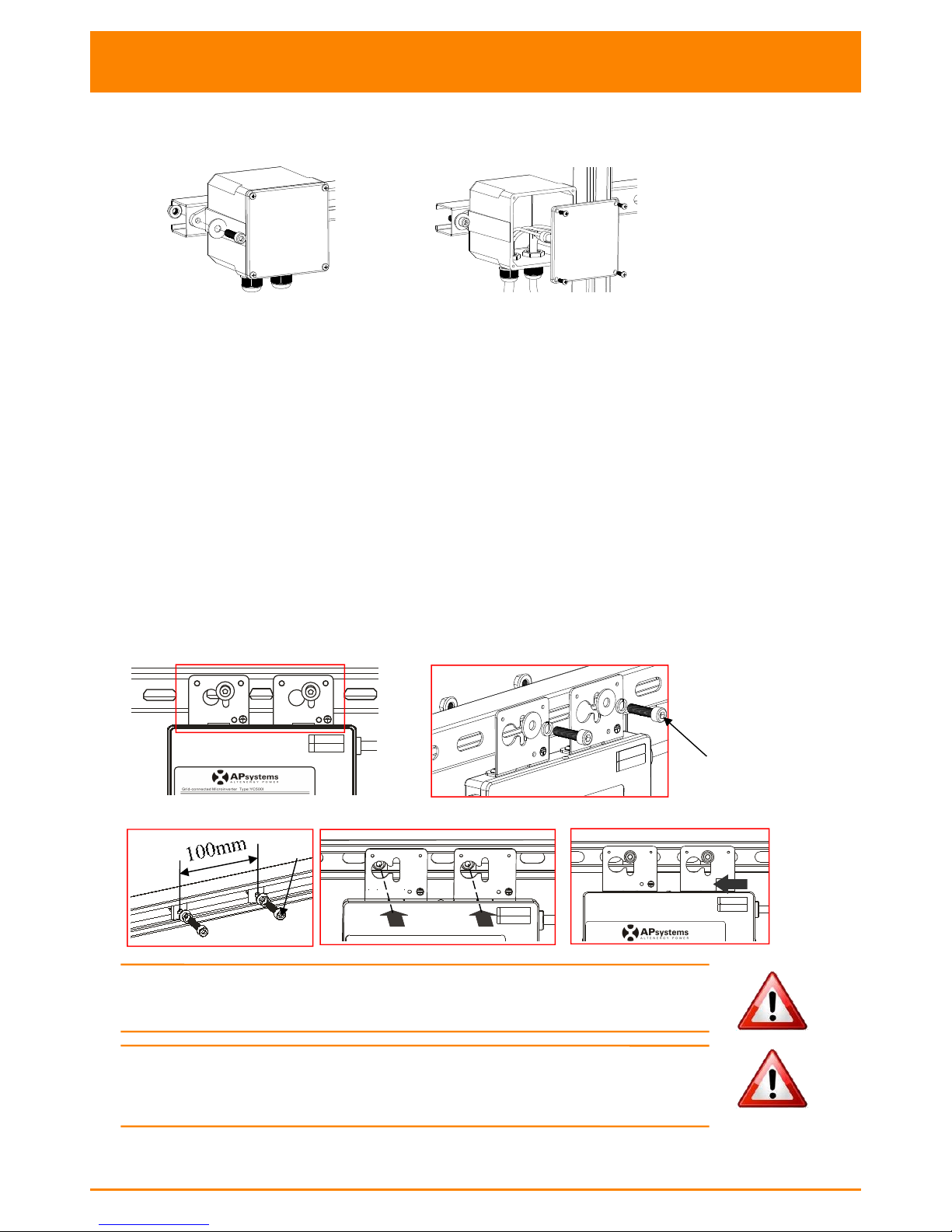

Step 2 - Install the AC branch circuit junction box....................................................................................... 9

Step 3 - Attach the APsystems Microinverters to the racking or the PV module frame..............................9

Stpe 4 - Connect the APsystems microinverter to AC bus cable................................................................ 10

Step 5 - Install a AC bus protective end cap at the end of AC bus cable....................................................11

Step 6 - Connect APsystems Microinverters to the PV Modules................................................................11

Step 7 - Complete the APsystems installation map....................................................................................12

Step 8 - Place a Warning Notice................................................................................................................. 13

APsystems microinverter system operating instructions................................................................. 14

Troubleshooting................................................................................................................................. 15

Status Indications and Error Reporting...............................................................................................................15

Start up LED.................................................................................................................................................15

Operation LED............................................................................................................................................. 15

Other Faults.................................................................................................................................................15

Troubleshooting a non-operating APsystems Microinverter............................................................................. 16

Maintenance...................................................................................................................................... 16

Replace a microinverter.....................................................................................................................17

Technical Data.................................................................................................................................... 18

APsystems YC500I Microinverter Datasheet...................................................................................................... 19

Wiring Diagram.................................................................................................................................. 20

Sample Wiring Diagram - Single Phase...............................................................................................................20

Sample Wiring Diagram - Three Phase............................................................................................................... 21