3

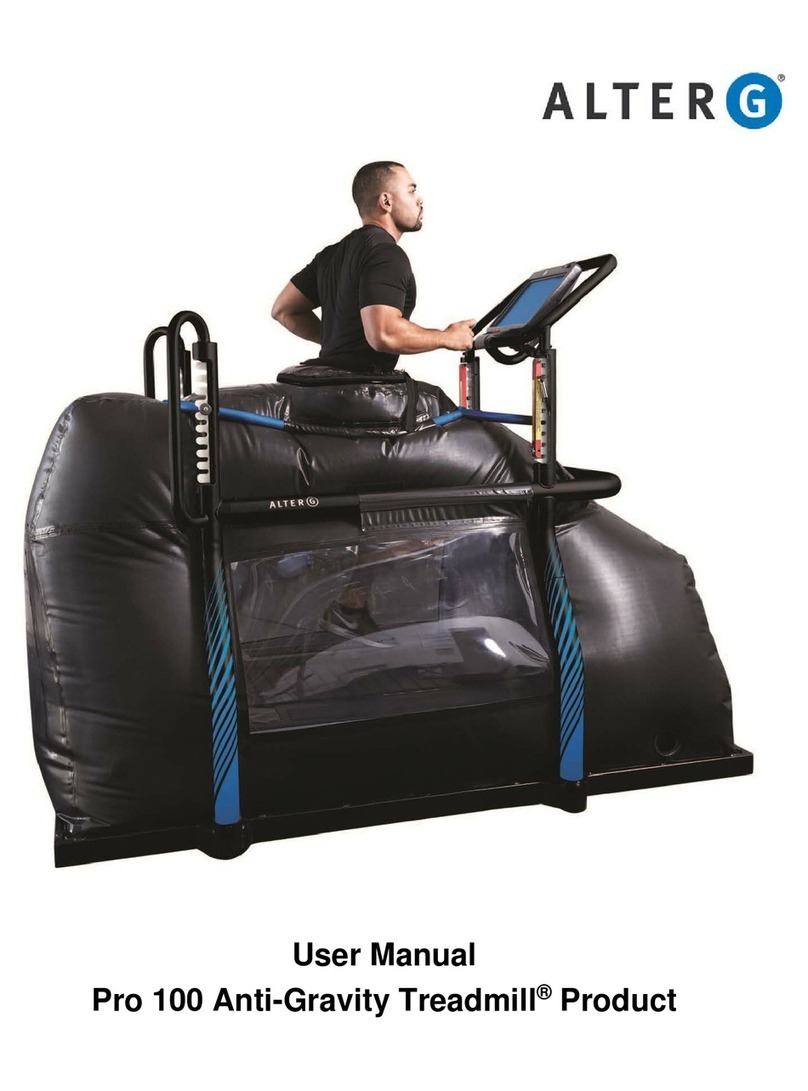

AlterG Installation Manual 105440 rev C

TABLE OF CONTENTS

Table of Contents ...................................................................................................................... 3

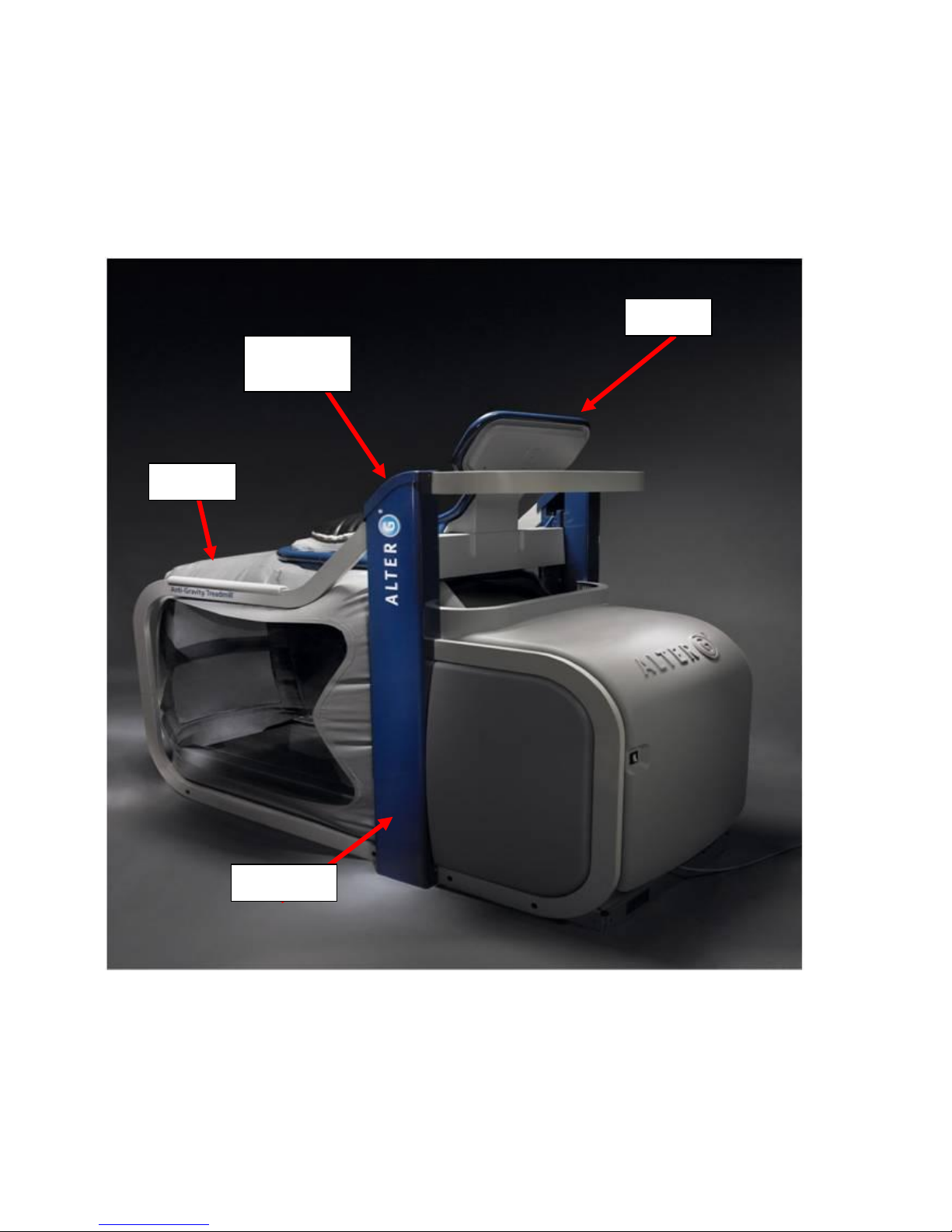

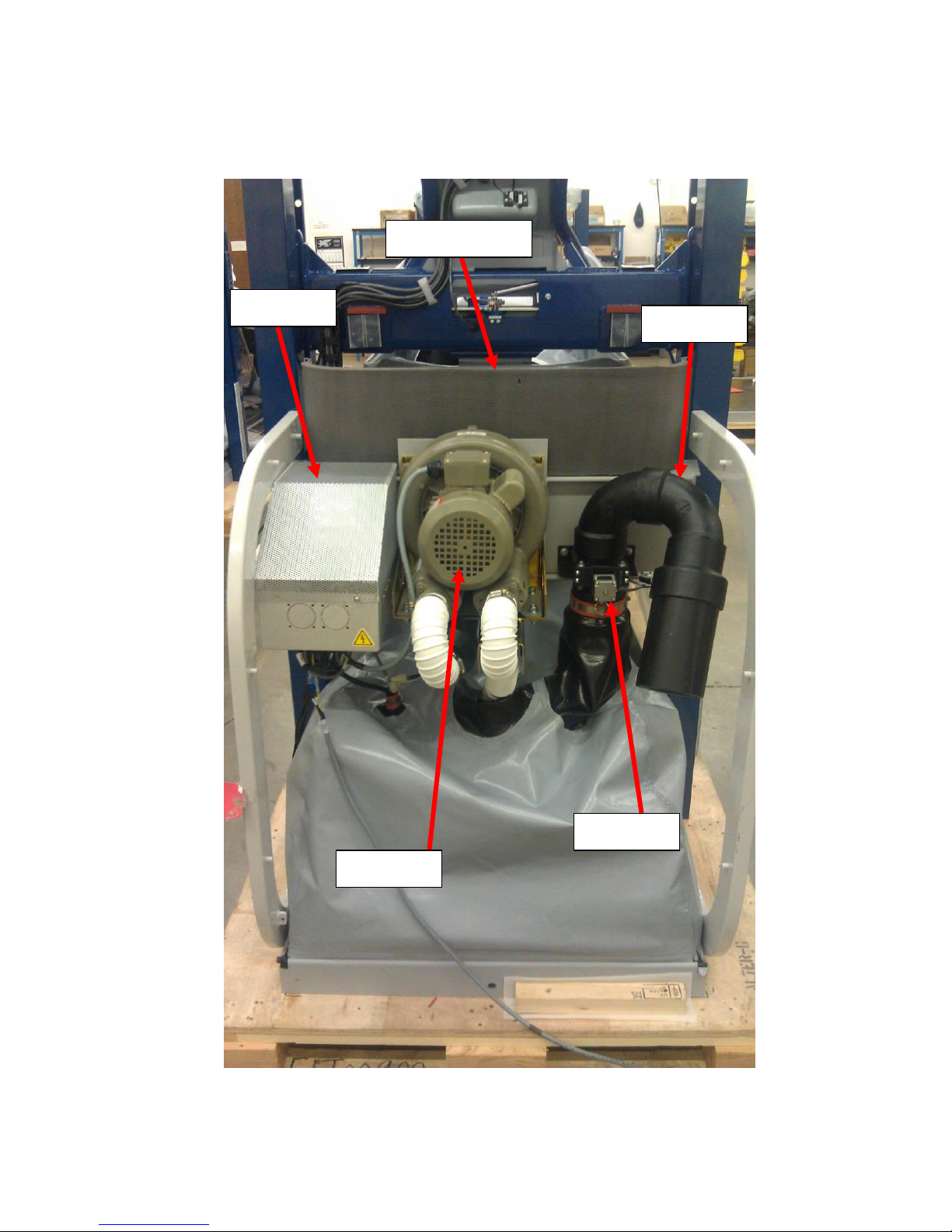

AlterG COMPONENT IDENTIFICATION ...................................................................................... 4

Exterior Components ............................................................................................................ 4

Interior Components............................................................................................................. 5

GENERAL INSTALLATION GUIDELINES ....................................................................................... 6

Safety..................................................................................................................................... 6

Tools ...................................................................................................................................... 6

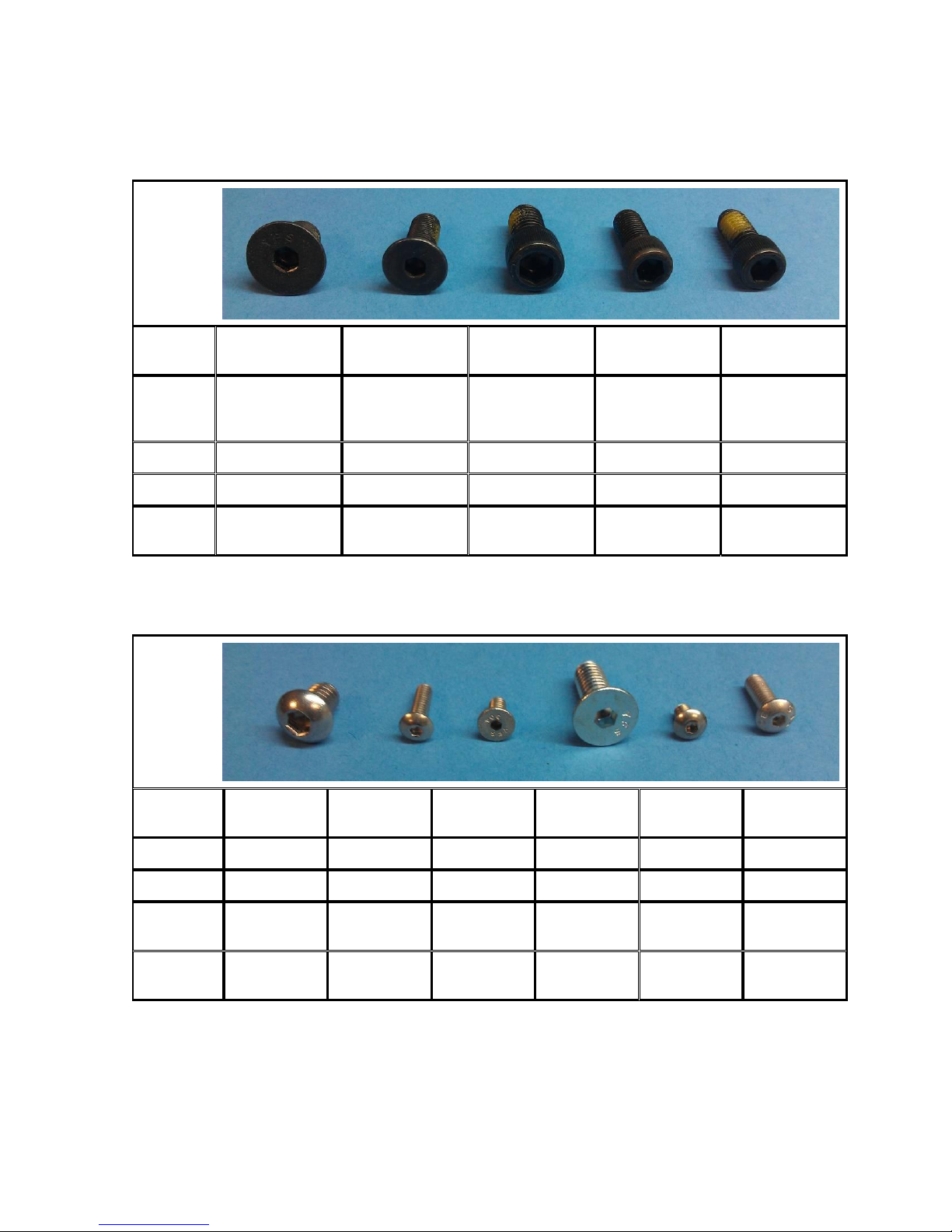

Fasteners and Torque Specifications..................................................................................... 7

SITE REQUIREMENTS................................................................................................................. 8

Treadmill Dimensions............................................................................................................ 8

Electrical Requirements ........................................................................................................ 8

INSTALLATION OF THE FULLY ASSEMBLED ALTERG (roll-in)...................................................... 9

Moving the AlterG System to a Location .............................................................................. 9

Removing the AlterG from the Pallet.................................................................................... 9

Removing the AlterG from the Dollies.................................................................................. 9

Preparing the System for Operation ................................................................................... 10

ASSEMBLY INSTRUCTIONS FOR THE DISASSEMBLED UNIT ..................................................... 12

Moving the AlterG............................................................................................................... 12

Unpacking............................................................................................................................ 12

Base Assembly..................................................................................................................... 15

Installing the Stanchion Assembly ...................................................................................... 16

Installation of the Cockpit ................................................................................................... 18

Installation of the Cable Guide ........................................................................................... 20

Diagnostic Mode ................................................................................................................. 22

Check Drive Belt Tension..................................................................................................... 22

Check Treadbelt Tracking .................................................................................................... 23

Check Treadbelt Tension ..................................................................................................... 23

Bag Installation.................................................................................................................... 24

Rail Installation.................................................................................................................... 29

Install the Main Power Cable .............................................................................................. 31

Final Installation Steps ........................................................................................................ 32