Vers. 1.0 - 17.01.97 1

1. Preface

Topax Hygiene Systems are used for rinsing, foaming or spraying of detergents and

sanitisers. The formation of foam is performed by mixing water, detergent or sanitiser

and compressed air in a specially designed injector system.

It is important that your operational staff reads these directions for use prior to

installation and start of operation. Operation as laid down in the directions for use will

ensure an optimum level of hygiene in your factory and a minimum level of

maintenance and repair work.

1.0 Application

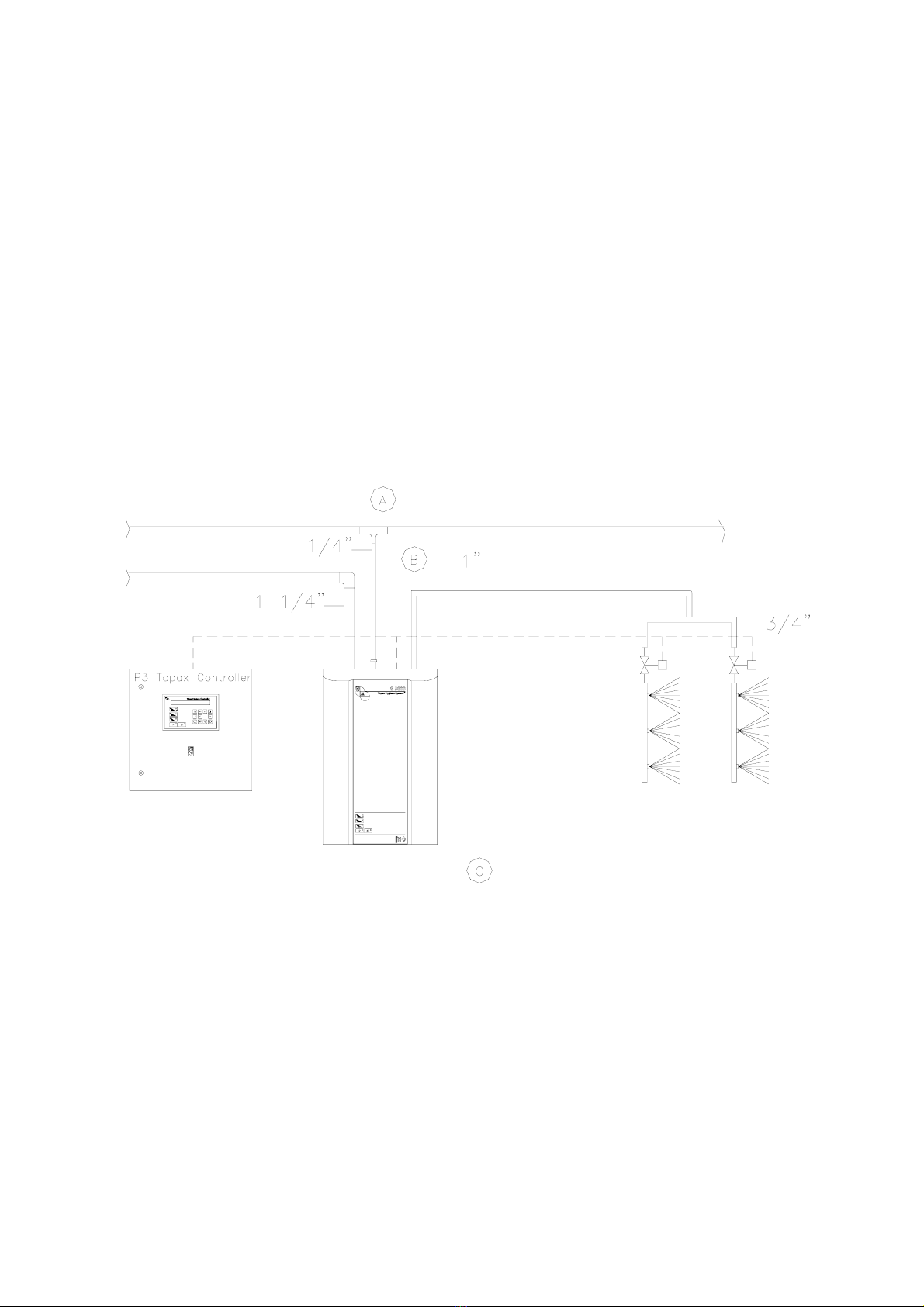

S 6000 and S 5000 are stationary cleaning stations designed to automatic cleaning.

Furthermore, manual S 3000 satellites can be connected to the S 6000. S 5000 is to be

connected to a main/pump station. We recommend the P3 Topax Hygiene Controller to

control the hygiene-cycles. The stations are made of corrosion resistant materials,

mainly stainless steel, and are therefore especially suitable for application within the

food industry. If you need further information, please contact Henkel-Ecolab.

Standard programmable hygiene stages are as follows:

a) pre-rinse with water

b) clean with foam

c) rinse off with water

d) sanitise with spray or foam

e) final rinse with water

1.1 Special Warnings

The special warnings CAUTION, ATTENTION and NOTE used in this Technical

Manual have the following meanings:

CAUTION: This term is used to highlight the fact that complete or even partial

failure to properly adhere to operating instructions, working

instructions, specified working sequences and similar can cause

personal injuries or accidents.