Clean Athena Reset User manual

User Manual

1-YEAR

MANUFACTURER

WARRANTY

READ ALL INSTRUCTIONS BEFORE USING, OR SERVICING, THIS EQUIPMENT. KEEP THIS

MANUAL IN A LOCATION THAT IS READILY AVAILABLE TO USERS AND SERVICE TECHNICIANS.

English (Original Instructions)

2-Part

Concentrate

Foamer

Reset

Foamer

Page 2Athena®Reset Foamer

1. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Product Overview ......................................... 5

Product Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Specifications...................................... 5

Product Components....................................... 6

3. Operation .................................................... 8

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5. Troubleshooting .............................................11

6. Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Contents

Page 3Athena®Reset Foamer

WARNING

!

1. Safety

PEOPLE OR OBJECTS CAN BE HURT OR DAMAGED IF THIS UNIT IS NOT USED CORRECTLY!

Failure to read all the instructions before operating the unit may result in personal injury

or death from the improper use or the chemical solution. Anyone handling, operating

or using the unit must read, and understand, the instructions in the manual. The buyer

assumes all responsibility for safety and proper use in accordance with the instructions.

Using, or servicing, the unit without proper protective clothing,

gloves, and eye wear may result in serious injury such as burns,

rashes, eye, throat or lung damage and death. Always wear

protective clothing, gloves, and eye wear when using, or servicing,

the unit. Protect eyes, skin, and lungs against drifting spray.

Chemical solutions may pose a health risk and death if they contact the skin or eyes,

are inhaled or swallowed. Always read, and follow, all chemical safety precautions and

handling instructions provided by the chemical manufacturer and the Safety Data

Sheet (SDS) associated with the chemical solution being used before using the unit.

Pressure within the equipment may cause an unexpected release of the chemical

solution and cause serious injury such as burns, rashes, eye damage, throat or lung

damage and death. Always depressurize and clean the unit after each use. Release any

remaining air pressure by twisting the pressure relief valve to the right ½ turn. Never

leave the unit unattended while pressurized.

Using the unit with fluid temperatures above 100°F (37.77°C) may result in scalding,

burns, serious injury or death. DO NOT use a solution with a temperature above 100°F

(37.77°C).

Operating the unit when damaged or leaking may result in exposure to chemical

solutions, serious injury or death. Never use the unit if it is damaged or leaking.

Never point the discharge wand at yourself, another person, or any object you do not

want covered in chemical.

Using incoming air pressure exceeding 100 psi (7 bar) may result in pressure buildup,

explosion, serious injury or death. DO NOT exceed 100 psi (7 bar) incoming air pressure

when operating the unit.

Use of hydrocarbons and flammable products may result in explosions, fire and serious

injury or death. Never use hydrocarbons or flammable products with the unit.

Mixing an alkaline with an acid may result in a chemical reaction. Overheating of the

mixture may cause it to splatter caustic compounds or release hazardous fumes, gas

and vapors. Always flush the unit with fresh water for five (5) minutes when switching

from an alkaline to an acid or an acid to an alkaline.

Page 4Athena®Reset Foamer

NOTICE

Servicing, or modification, of this unit with parts not listed in this manual may cause the unit to

operate improperly. Do not use unauthorized parts when servicing the unit.

Use of an air lubricator before the unit may result in diminished performance and damage to the

unit. Do not use an air lubricator before the unit.

Moisture in the air lines will damage the pump and diminish the pumps life. The air must be filtered,

clean, dry and free of moisture. If needed, install an air dryer before the unit.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials, old machine components, and hazardous fluids in

an environmentally safe way according to local waste disposal regulations.

Page 5Athena®Reset Foamer

2. Product Overview

Product requirements

Compressed air requirements 50 psi with 5-10 SCFM (141-283 l/min)

Liquid temperature range 40-100˚F (4.4-37˚C)

Chemical compatibility

Chemical products used with this equipment must be formulated for

this type of application and compatible with unit materials and pump

seals. For more information on chemical compatibility, consult the

manufacturer or SDS for your product or contact our customer service

department.

Power type Compressed air

Chemical pickup type Draws from concentrated product

Dilution ratio 1 oz (29.57 ml) of each chemical per 1 gallon (3.8 liters) of water

Number of products unit can draw from Two products, simultaneously

Capacity

15 gallons (56.8 liters) of water

5 gallons (18.9 liters) of Athena® PERAFOAM

5 gallons (18.9 liters) of Athena® RESET

Discharge line length/diameter 50 ft. (15.2 m) hose, with 3/4 in. (19 mm) inside diameter

Discharge wand/tip type 10 in. (3.9 cm) stainless steel wand with 80 degree fan tip and ball valve

Pump seals Kalrez

Wheel type Two 10 in. (25.4 cm) non-marking wheels

Two 5 in. (12.7 cm) casters—one with lock

Product specifications

Page 6Athena®Reset Foamer

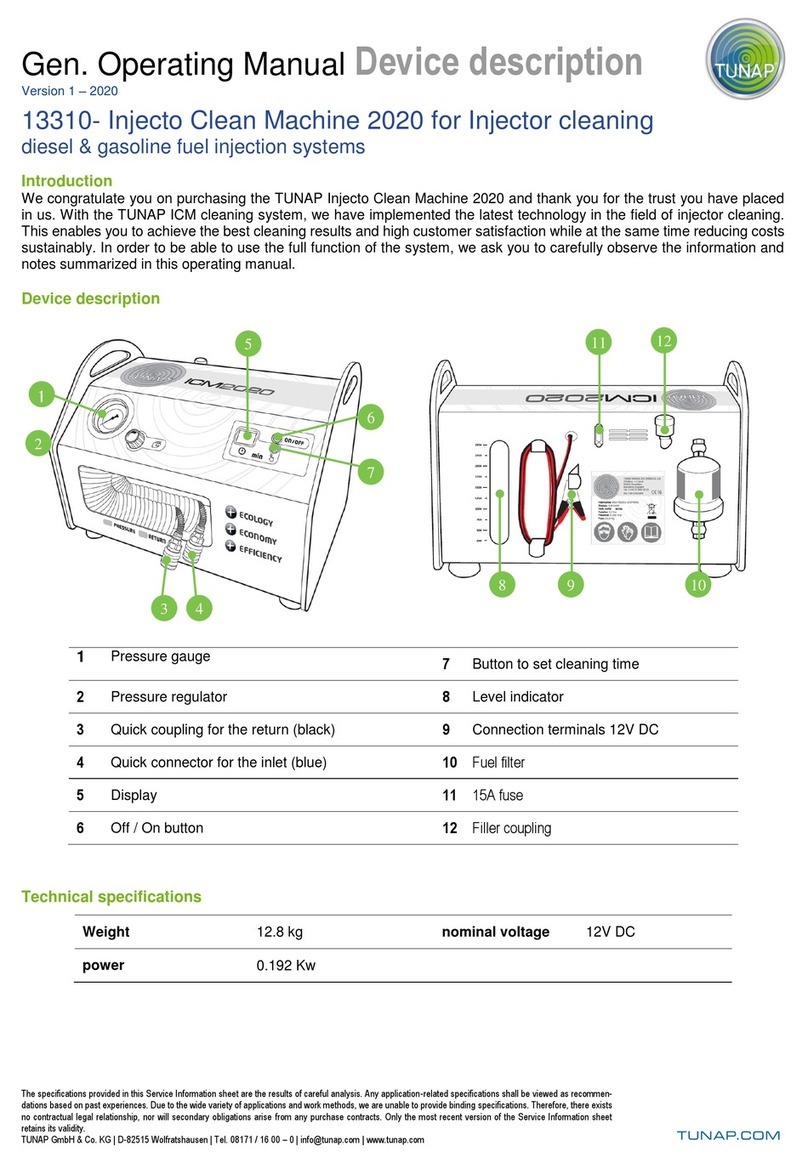

USA

USA

8

9

10

11

5

3

1

Back plate assembly • Inside view 6 7

2

4 4

1. Hinged back plate

2. Orange metering tips

3. Dual injector

4. Suction lines

5. Quick change pump

6. Flow control valve

(includes black knob)

7. Air regulator

8. Air pressure gauge

9. Check valves

10. In-line strainer

11. Suction line valve

Product components

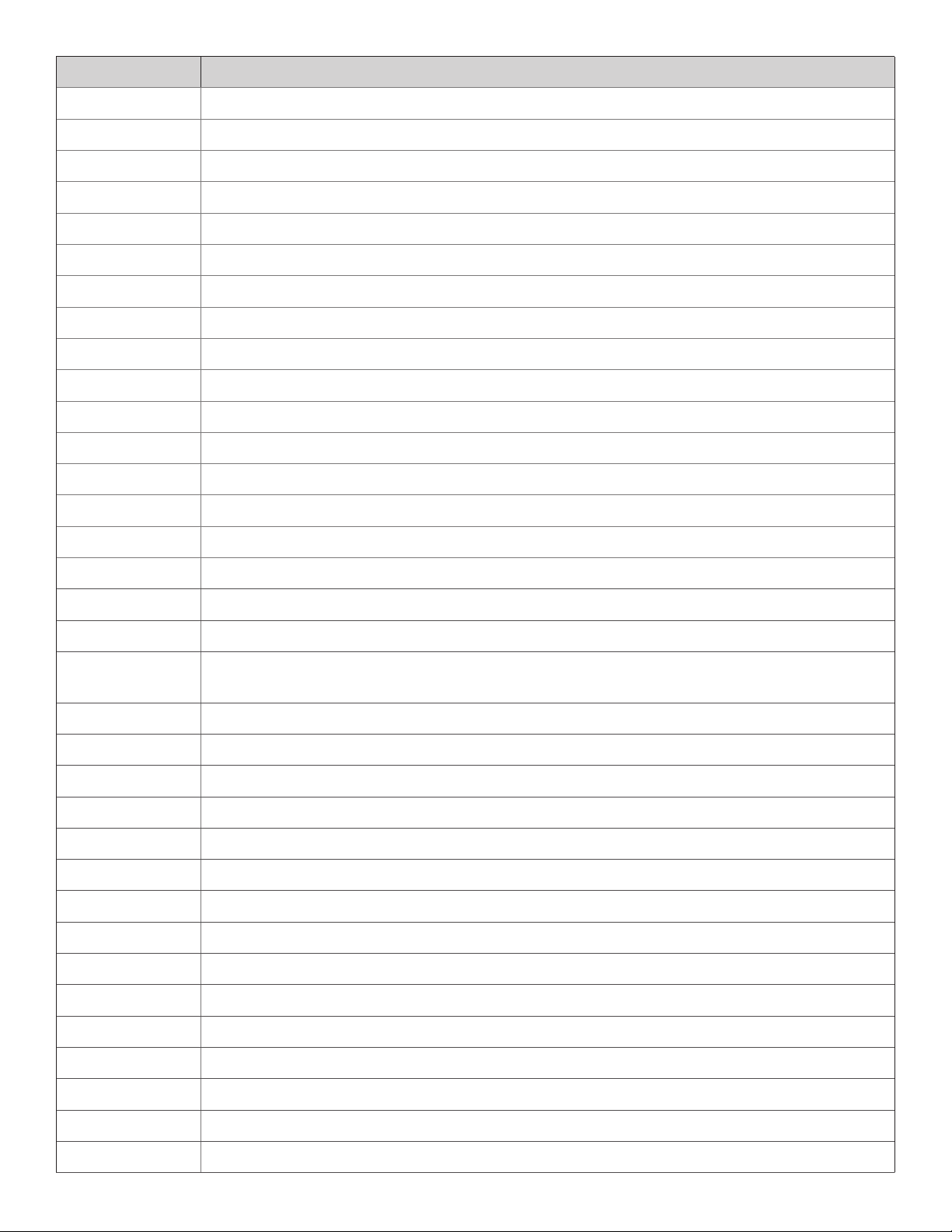

Before you begin, get to know the Athena®Reset Foamer components that you will need to use,

adjust or assemble.

Page 7Athena®Reset Foamer

14

18 6

Tank assembly • Front view

12

Tank assembly • Back view

16

13

15

4

4

17

11

12. Discharge ball valve

13. Foam wand with spray tip

14. Hinged cap assembly

15 Chemical jug

16. Tank

17. Drain plug

18. Air fitting

Page 8Athena®Reset Foamer

USA

USA

Chemical

suction line

Chemical

suction line

2

Injector

inlet barbs

Dual chemical

injector

1

3

3

2

3. Operation

1. Fill the tank with water.

2. Follow all instructions from chemical

manufacturer. Fill the chemical container with

chemical concentrate.

2a. Fill Perafoam chemical container with

Athena®Perafoam.

2b. Fill Reset chemical container with

Athena®Reset.

3. Connect each suction line to quick-connect

fittings on 5 gallon chemical jugs.

4. Verify that the suction line valve at the base of

the suction line is open, to allow fluid into the

suction line.

5. With the discharge ball valve in the closed

position, plug an air line into the air fitting.

6. Slowly open the discharge ball valve to begin

foaming. The discharge ball valve should be

completely open while foaming.

7. While the unit is running and discharging

product, adjust the flow control valve as

needed to regulate the wetness or dryness of

the foam following the steps below:

a. Close needle valve completely in

clockwise direction.

b. Open needle valve in counter-clockwise

direction 3 complete turns.

c. Continue to open needle valve in ¼

turn increments, allowing 30 seconds

between adjustments, until desired

consistency of foam is achieved.

8. Close the discharge ball valve to stop foaming.

Page 9Athena®Reset Foamer

4

7

13

11

After Use Instructions

11. Disconnect the chemical intake lines from

the chemical containers and connect it to a

container of clean water. Make sure that the

unit tank still contains water.

12. Activate the unit and allow it to run for 2-4

minutes, or until all chemical has been

flushed from the system.

13. Disconnect the air line from the air fitting.

14. Open the discharge ball valve to relieve any

pressure remaining in the system.

15. Close the ball valve after all pressure has

been relieved from the system. Store the

unit with the discharge ball valve in the

closed position.

5 8 15 614

Page 10Athena®Reset Foamer

4. Maintenance

Performing any maintenance with the unit

turned ON, plugged into an electrical power

source and connected to the air and water

supply may result in serious injury or death.

Always ensure that the unit has been turned

OFF, unplugged from the electrical power

source, and disconnected from the air/water

supply before conducting any maintenance.

WARNING

!

NOTICE

Servicing, or modification, of this unit with

parts not listed in this manual may cause

the unit to operate improperly. Do not use

unauthorized parts when servicing the unit. Use

of unauthorized parts will void the warranty.

To keep your foam unit operating properly,

periodically perform the following maintenance

procedures:

• Inspect the pump for wear and leaks.

• Inspect all hoses for leaks or excessive wear.

Make sure all hose clamps and push-fittings

are in good condition and properly secured.

• Replace the filter located within the air

regulator as needed. Clean by unthreading the

air regulator bowl from the air regulator.

• Check the chemical metering tip, suction line

and strainer for debris and clean as needed.

• Drain your air compressor tank on a regular

basis to help extend pump life. An air source

with a high moisture content will accelerate

pump wear.

Note: If your air source has a high moisture

content, you may wish to install a water

separator (item number WS-20CFM, sold

separately) before the unit.

Page 11Athena®Reset Foamer

5. Troubleshooting

Issue Solution

Air regulator bowl or air

filter has debris such as

water, oil, or rust particles

• Clean by unthreading the air regulator bowl from the air regulator.

Pump is cycling improperly

due to lack of air pressure

• The flow control valve is open too far. Close and readjust the flow control valve as

described in the Operation section.

• Ensure proper foaming chemical and concentration are being used.

Air passes through the

pump without cycling • The pump needs to be replaced.

The solution backs up into

the air regulator bowl • The check valve needs to be replaced.

Foam comes out wet, no

matter where the needle

valve is positioned

• Check for proper air pressure on the air gauge. The air regulator is factory set

at 50 psi (3.4 bar). Operating range is 40 to 80 psi (3 to 5 bar) with 5 to 10 CFM

(141.6 to 283.3 l/min).

• The check valve may need to be replaced.

The unit operates at a

reduced pressure

• Check the chemical metering tip, suction line and strainer for debris or damage.

Clean or replace as needed. To prevent damage to the unit, the strainer must

always be used.

• Check the air compressor supplying the unit. If the pressure is less than 40 psi, turn

the unit o until the compressor can catch up.

• If the air supply is 50 psi (3.4 bar) or above, check the air gauge,

which should read near 50 psi (3.4 bar). If the air gauge reads more or less

than 50 psi (3.4 bar), adjust the pressure by turning the knob on the top of the

air regulator.

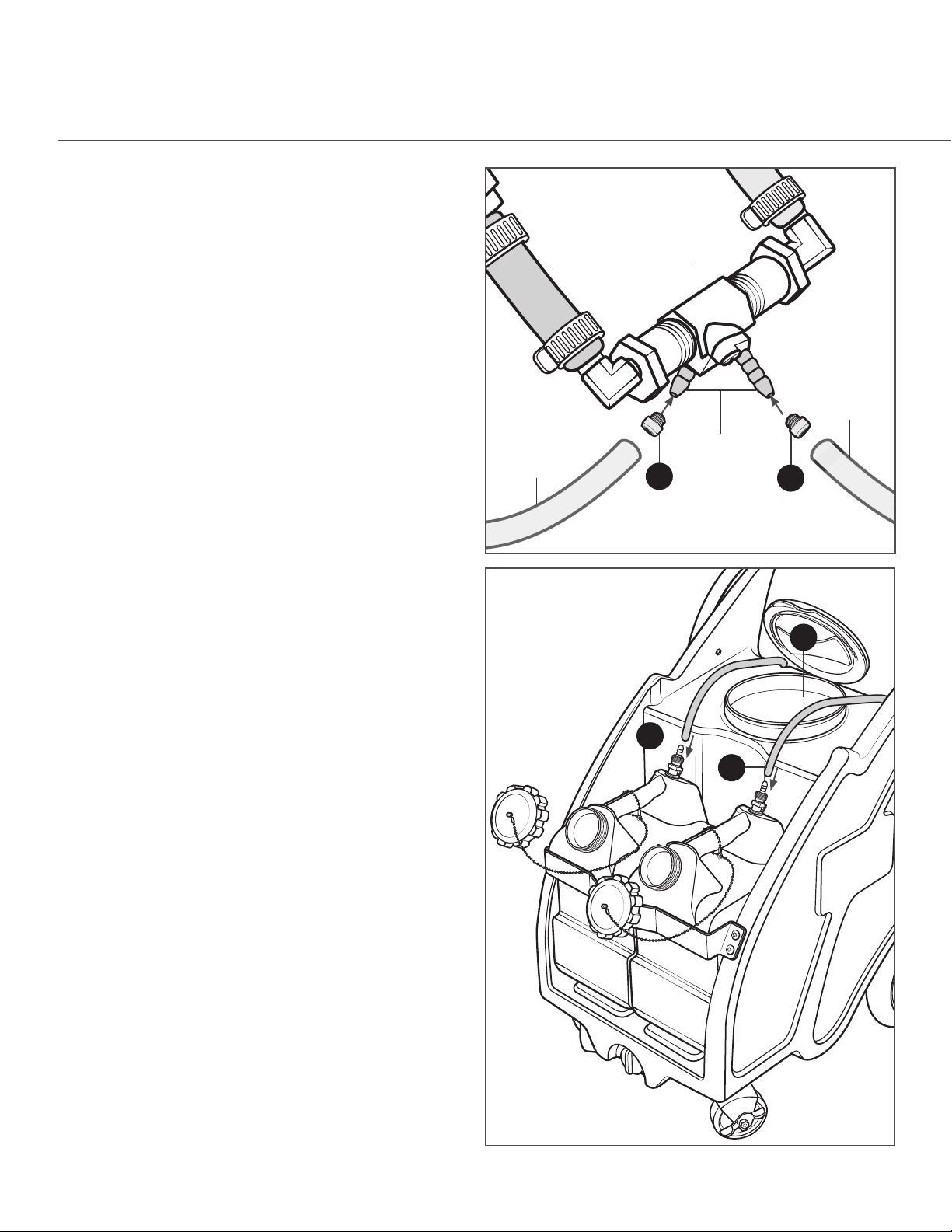

• Check if the stainless steel mixing mesh is plugged. Remove and clean it by

following the instructions below:

1. Be sure the foam unit is not plugged into an air supply and be sure to

relieve all stored pressure in the unit by having the ball valve in the open

position.

2. Remove the stainless hose barb from the tee fitting.

3. Remove the screen and the mixing mesh from inside the tee fitting.

4. Clean any particles from the mixing mesh and the screen.

5. Replace the mixing mesh and then the screen into the back of the tee and

screw the stainless adaptor back into the tee. It is recommended to use a

pipe thread sealant when reinstalling the stainless adaptor back into the tee

fitting. If the mixing mesh has a lot of foreign particles in it, make sure the

strainer is still in place.

Page 12Athena®Reset Foamer

USA

USA

C L- H1 4C

CL-H34-50

CL-BPS-58SO

CL- AP25

CL-AKSS34

CL-DFP7

CL-W15

C L- NV 14Y

6. Parts CL- H V6 0

CL-ST80150SS

CL-P203CT-FS

C L- H1 4C CL-H38C CL-QCPP-M-HAST

CL-QCPP14HB-HAST

CL-SSW1210FM

CL-H38B-F

Wand assembly

Back Plate

CL-J5BKS

Jug assembly

CL-J5

CL- AG 10 0

CL-CV38-AP C L- R25

CL-JC35B-TAV

CL-DP-A

CL-TA NK-1 5N - C - A

CL-CST5SS-L

CL- C ST 5S S

CL-H14B-F

CL-H38B-F

CL-HBSSEL1438

CL-HHPB3414

CL-PVCV34FM

C L-S CI - 125 X 2

C L- P5 6K

CL-STR38-IL

CL-CV38-AP

Page 13Athena®Reset Foamer

Item number Description

CL-AG100 1.5 in. dry model 20 dual scale gauge

CL-AKSS34 SS anti-kink spring for 3/4 in. hose

CL- AP25 Air fitting 1/4 MPT x plug-brass

C L- C S T5 SS 5 in. S.S. Swivel caster with 4 in. wheel

C L- C S T5 SS - L 5 in. S.S. Swivel caster with 4 in. wheel and lock

CL-CV38-AP White PVC check valve 3/8 barbs - Hastelloy spring - Teflon ball

CL-DFP7 7 in. hinged cap assembly - includes black cap, lid flange and hinge pin

CL- D P- A Drain plug assembly for natural portable units - includes plug and gasket

CL-H14B-F 1/4 in. blue hose-hybrid TPE-available per ft.

CL- H 14 C 1/4 in. ID (3/8 in. OD) clear polyvinyl tubing - available per ft.

CL-H34-H34-50 H34-50 ft. of 3/4 in. replacement hose

CL-H38B-F 3/8 blue hose-hybrid TPE-available per ft.

CL- H 38 C 3/8 in. ID (1/2 in OD) clear PVC tubing - available per ft.

CL-HBSSEL1438 Stainless hose barb 1/4 MPT x 3/8 barb elbow

CL-HHPB3414 Hex head poly bushing 3/4 MPT x 1/4 FPT

CL- H V6 0 1/2 in. stainless ball valve - welded nut

CL-J5 5 Gallon natural jug

CL-J5BKS 5 Gallon natural jug-black cap-suction

CL-JC35B-TAV Black 3.5 in. one way vented cap polypropylene-EPDM gasket and check valve-bead chain

tether assembly

CL-NV14Y Flow control valve - includes black knob

CL-Orange-tip Orange metering tip for dema injector

CL-P203CT-FS Foot strainer for the P203CT

CL- P56K Pump with Kalrez seals - includes hose barbs, air fitting, and exhaust barb

CL-PVCV34FM PVC valve 3/4 in. FPT x 3/4 in. MPT

CL-QCPP-M-HAST 3/8 in. panel mount socket - suction 3/8 ID x quick connect - Hastelloy spring - 11/16-24 thread

CL-QCPP14HB-HAST 1/4 in. in-line hose barb - polypro body - Hastelloy spring

CL- R 25 Air regulator - 1/4 FPT two port 1/8 FPT two port - includes filter and bowl

CL-SCI-125X2 Stainless chemical injector-.125 Orfice-dual barb-3/8 MPT

CL-SSW1210FM Polished - stainless wand-1/2 in. MPT x 1/2 in. FPT-10 in. long

CL-ST80150SS Spray tip-80 degree-15.0 GPM-stainless-1/2 MPT

CL-STR38-IL In-line strainer-3/8 barb-EPDM gasket-20 mesh SS

CL-TA NK- 15N - C -A 15 Gallon concentrate tank natural in color-assembly

CL-W 15 Non-marking wheel for portable units

CL-WS-20CFM Water Seporator

Page 14Athena®Reset Foamer

WARRANTY

For technical support and troubleshooting please call or email:

(844) 333-1818

suppor[email protected]

Warranty; Limitations. Athena warrants that the Reset Foamer and replacement parts (“Goods”) shall be free

from defects in material and workmanship under proper and normal and recommended use for a period of 1 year

from the date of shipment. Goods shall be considered defective only if a defect exists that materially impairs

the value of the Goods to Customer and does not comply with Athena’s specifications (or, if none, does not

comply with normal industry tolerances or standards). Goods shall not be defective if the Goods comply with

Customer’s instructions or if the Goods have been modified, have been subject to misuse or neglect or if the

Goods are not operated in a typical fashion. In accordance with the terms of this limited warranty (“Warranty”),

Athena will, at its option, either replace any such defective Goods or parts thereof or issue Customer a credit

for the purchase price of the defective Goods, provided that written notice of the defect is received by Athena

within 30 days of the appearance of such defect and within the 1-year warranty period. If notice is not given

by the required deadlines set forth in this paragraph, any claim for breach of warranty is waived and Athena

shall not be liable. Upon receipt of notice of a possible defect in the Goods, Athena shall issue instructions

for their disposition. No Goods shall be returned to Athena without its prior consent. Transportation charges

for return and replacement under the Warranty will be borne by Athena if the Goods are defective. Under no

circumstances will Athena’s liability exceed the purchase price of the defective Goods.

THE TERMS ABOVE SET FORTH CUSTOMER’S SOLE AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE

GOODS OR ANY BREACH OF WARRANTY. EXCEPT AS SET FORTH IN THE PARAGRAPH ABOVE,

FOAMit MAKES NO WARRANTIES AS TO THE GOODS AND, IN PARTICULAR, MAKES NO WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND CUSTOMER IS SOLELY

RESPONSIBLE FOR DETERMINING THE PROPER APPLICATION AND USE OF THE GOODS. Athena shall

have no tort liability to Customer with respect to any of the Goods and shall not be liable for consequential

or incidental damages arising from any product defect, delay, nondelivery, recall or other breach. Customer

shall have no right of rejection or of revocation of acceptance of the Goods.

Reset

Foamer

Page 15Athena®Reset Foamer

Athena®Reset

Hard Surface Sanitizer & Disinfectant

Used between runs

Kills bacteria, mold, fungus, and yeast

Non-foaming

(unless used with Athena Perafoam)

EPA-registered peroxyacetic acid

Athena®Perafoam

Foam Adjuvant

Easily get full coverage

Warning:

Athena Reset and Athena Perafoam contain

hazardous chemicals. Always use in accordance

with instructions and wear appropriate personal

protective equipment (PPE).

Only use the Athena®Reset Foamer with

Athena®Reset and Athena®Perafoam

Athena®Reset Foamer

CL-FOAM2-50

This manual suits for next models

1

Table of contents