Working with the Elma Super Elite

6BA/Super-Elite/GB/0104 © Elma GmbH & Co KG

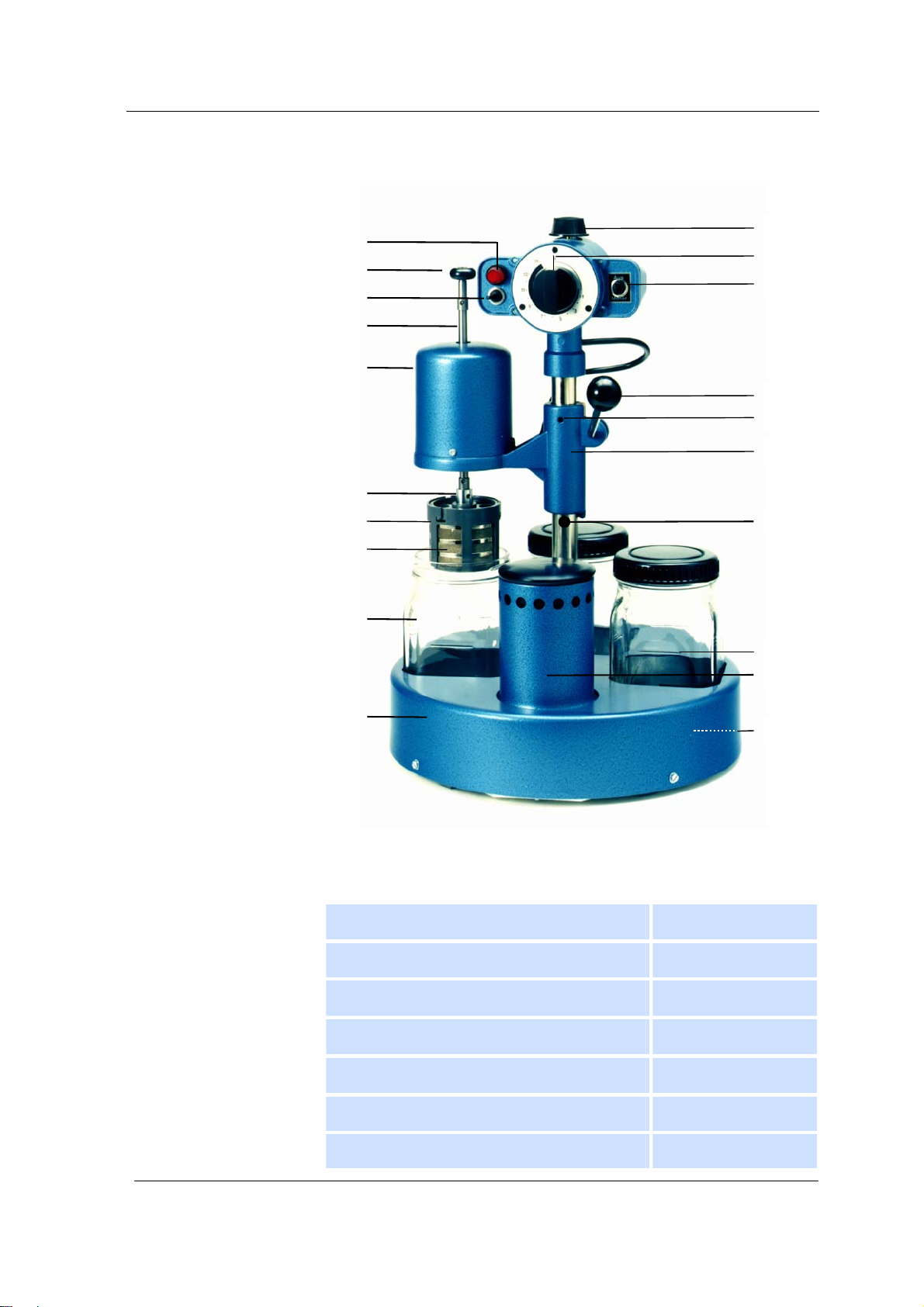

5.2 Cleaning Procedure

All the three glass jars should always be filled up 1 the mark (9).

The level of the liquid shall in any case be 1 cm above the

suction blade (11).

Important

The speed shall be regulated in all three liquids in such manner

only that a small suction is formed in the centre above the

basket, but the suction blades of the basket flange must not in

any case become visible. Otherwise excessive foam formation

would occur, and the basket would not be rinsed sufficiently

1. At the every start of each cleaning job switch on the heating

chamber (3) by means of the switch (12) separately

provided so as to have heating chamber (3) preheated for

drying as soon as cleaning in finished.

Proceeding

2. Bring the raised basket (10) into the glass jar (8) filled up

with ELMA Solution i.e. at the left of the heating tube (3). Fix

the bracket (6) by turning the knob (7) to the left and dip in

the basket in the liquid. Switch on the check-clock (17) for

controlling the time of cleaning. The cleaning process in the

first glass jar takes about 3 to 5 minutes depending on the

extent to which the parts are soiled.

3. Start the motor (13) by means of the switch (14) separately

provided.

4. Set the speed regulator to “slow” with the aid of the black

knob (15).

5. Before transferring the basket to the first jar to the next then

for centrifuging surplus solution raise the basket till the stop

is reached by means of the displaceable motor shaft (16)

(patent DBP. Nr. 869 025). Thereupon centrifuge for about

30 seconds at full speed.

6. After centrifuging in number 1 glass jar release the bracket

(6), move it upward und swing it on to the next jar No. 2

which contains distilled water Repeat the same process i. e.

turn the basket in the distilled water for one to two minutes

and then again raise up the basket till stop is reached and

spin it for one to two minutes. Thereafter place the basket in

the third jar, which contains the rinsing-solution. Lift the

basket afterwards and go to the heating tube.

7. Place the basket in the heating chamber (3) and dry for 1-2

minutes with raised basket at high speed. Built- in red

inspection lamp (20) for controlling the heating.

The surface of the heating chamber heat up considerably

during operation. The bottom of the heating chamber can reach

temperatures exceeding 90°C depending on the period of

operation.

CAUTION