- 2 - DN200 Installation Guide

Overview:

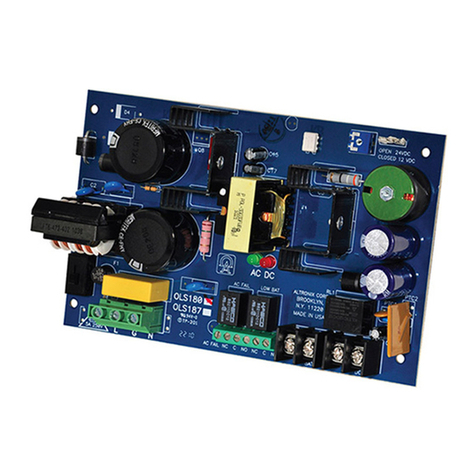

Altronix DN200 power supply/charger converts a 115VAC or 230VAC, 50/60Hz input into a 24VDC or 56VDC

regulated output. It can be mounted on a standard 35mm DIN Rail or on a shelf. This unit has a wide range of

applications for access control, security and CCTV system accessories that require additional power.

Specifications:

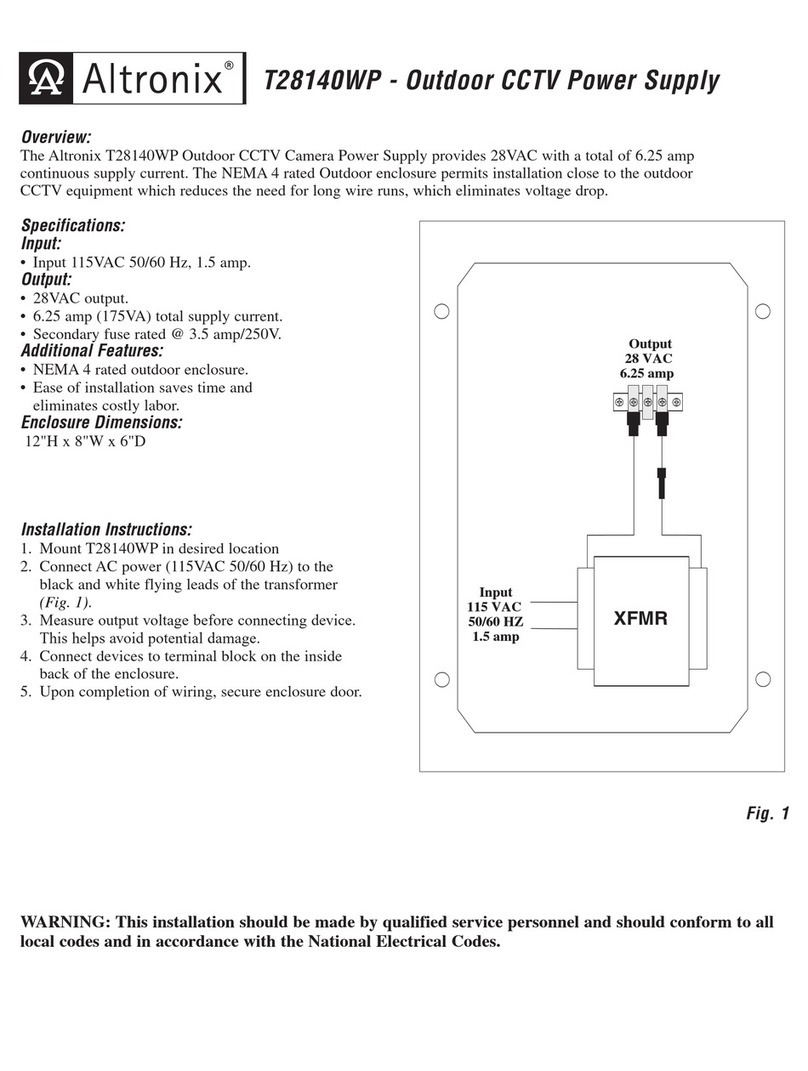

Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/NFPA 72/ANSI, and with all

local codes and authorities having jurisdiction. Product is intended for indoor use only.

Refer to Terminal Identification Chart on page 3 for a description of each terminal function.

1. Suitable for DIN Rail or shelf mounting (refer to page 3).

2. Set desired DC output voltage by setting SW1 on the front panel to the appropriate position (Fig. 1e, pg. 2).

3. Connect unswitched AC power (115/230VAC 50/60Hz) to terminals marked [L, G, N] (Fig. 1a, pg. 2).

Use 18 AWG or larger for all power connections (DC output, Battery).

Use 22 AWG to 18 AWG for power-limited circuits (AC FAIL and LOW BAT supervisory relays).

Keep power-limited wiring separate from non power-limited wiring (AC input, DC output,

Battery Wires). Minimum 0.25” spacing must be provided.

CAUTION: Do not touch exposed metal parts.

Shut branch circuit power before installing or servicing equipment.

There are no user serviceable parts inside. Refer installation and servicing to qualified service personnel.

4. Measure output voltage before connecting devices. This helps avoiding potential damage.

5. Connect devices to be powered to terminals marked [– DC +] (Fig. 1c, pg. 2).

6. When the use of stand-by batteries is desired, they must be lead acid or gel type.

Connect battery to terminals marked [– BAT +] (Fig. 1c, pg. 2).

Use two (2) 12VDC batteries connected in series for 56V or 24V backup.

Note: Separate enclosure must be used for housing batteries.

7. Connect appropriate signaling notification devices to AC and BAT supervisory relay outputs.

Maintenance:

Unit should be tested at least once a year for the proper operation as follows:

Output Voltage Test: Under normal load conditions the DC output voltage should be checked for proper

voltage level (see Power Supply Output Specifications Chart).

Battery Test: Under normal load conditions check that the battery is fully charged, check specified

voltage both at the battery terminal and at the board terminals marked [– BAT +] to

ensure that there is no break in the battery connection wires.

Note: Maximum charging current under discharges is 0.7A.

Note: Expected battery life is 5 years; however, it is recommended changing batteries in

4 years or less if needed.

Input:

• 115VAC or 230VAC, 50/60Hz, 2.5A.

Output:

• 24VDC @ 8A or 56VDC @ 4A selectable.

• Filtered and electronically regulated output.

• Short circuit and thermal overload protection.

Battery Backup:

• Built-in charger for sealed lead acid or

gel type batteries.

• Automatic switch over to stand-by battery when

AC fails.

• Maximum charge current 0.7A.

Supervision:

• AC Fail supervision (NC contacts).

• Low battery/battery presence supervision

(NC contacts).

Visual Indicators:

• AC input and DC output LED indicators.

• Trouble LED indicates power supply trouble.

Enclosure Dimensions:

8.85” x 4.825” x 1.95”

(225.8mm x 122.6mm x 49.5mm)