ALUTHERM | Boilers 6ALUTERM A 170 - 300 | Installation, user and service manual | instructions for user

Heating

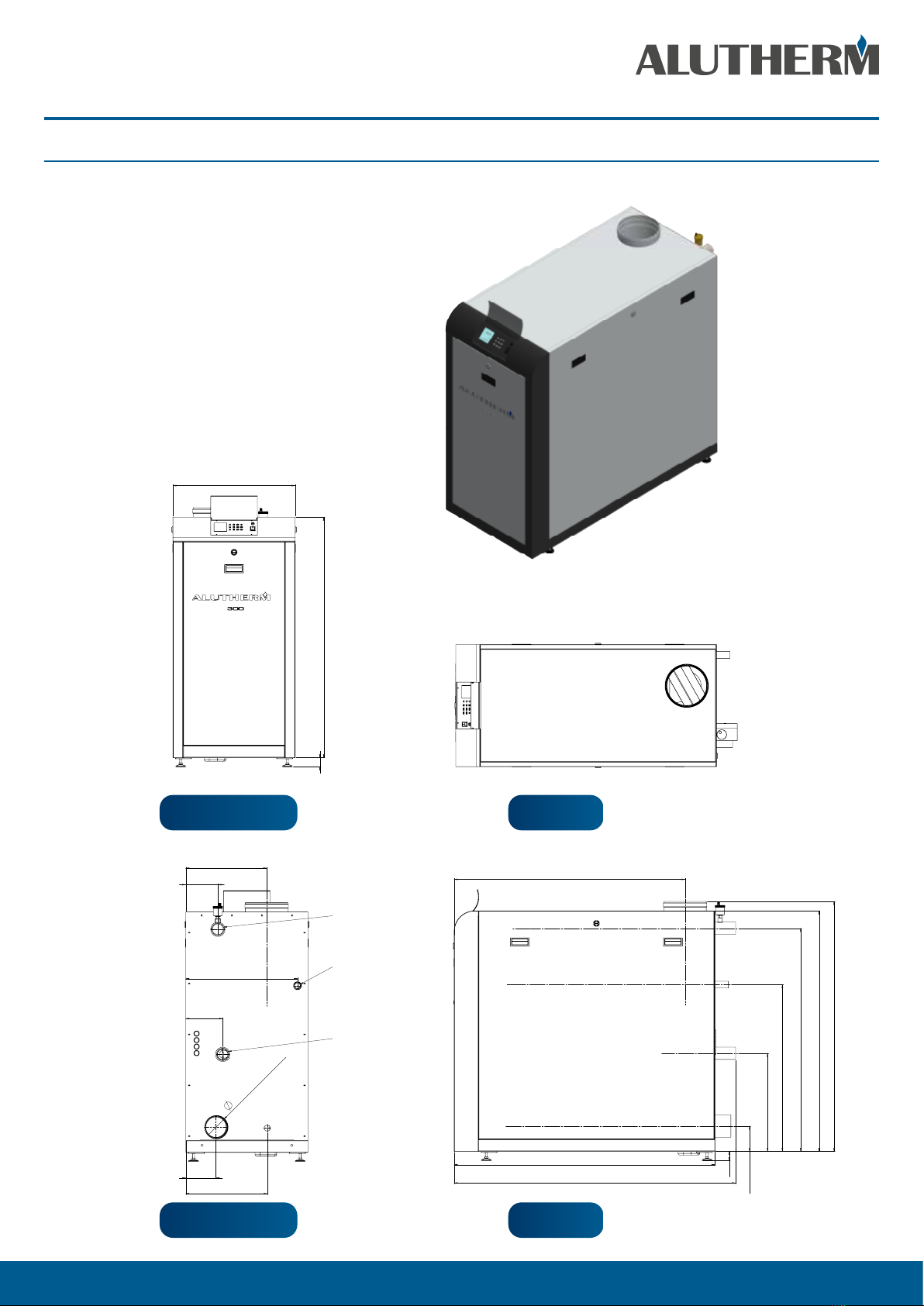

Alutherm A 170 - 300

2 TECHNICAL DATA

TECHNICAL DATA ALUTHERM A 170-300

A 170 A 210 A 260 A 300

Central heating

Nominal input max load (Hi) 168 210 252 290 kW

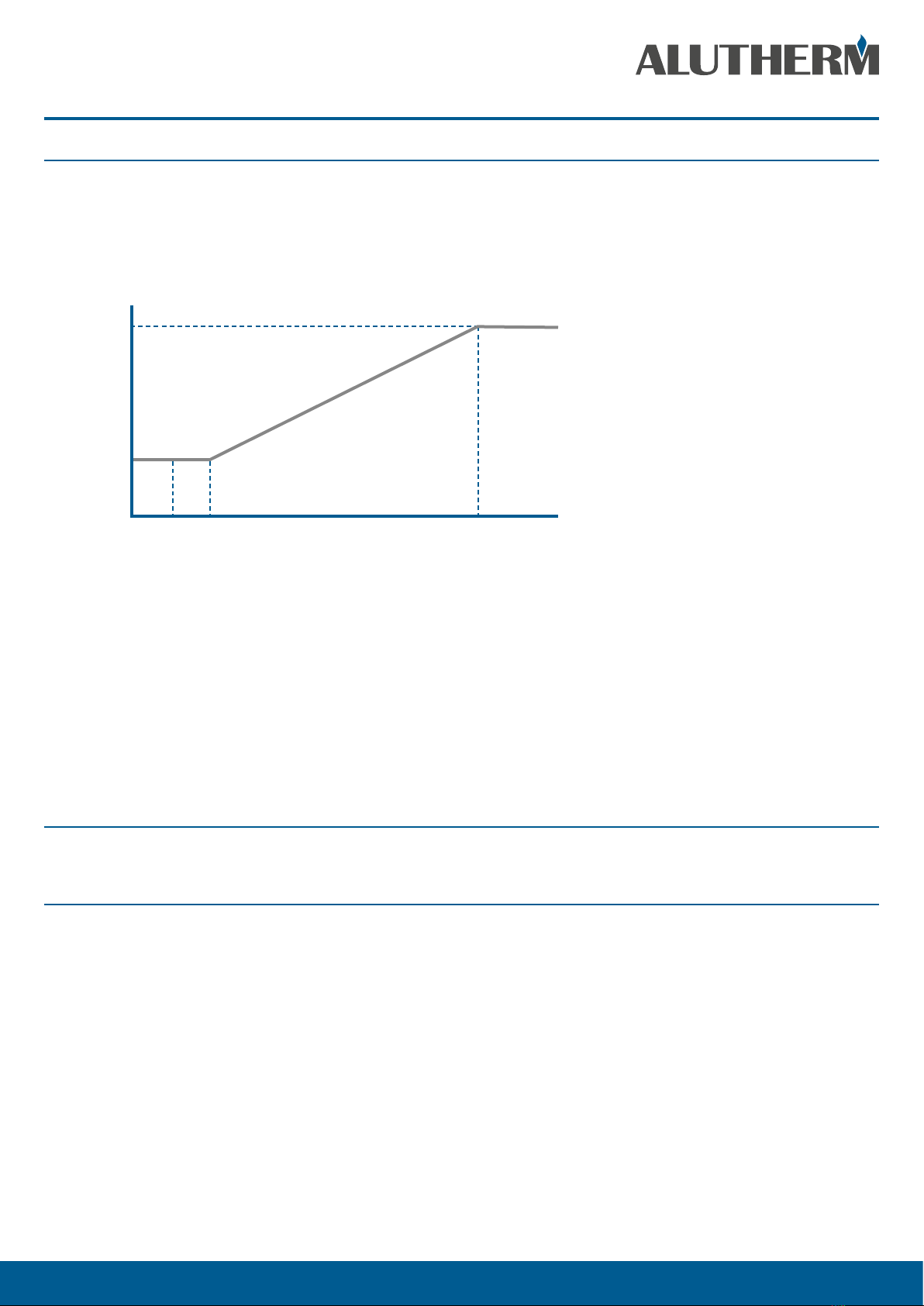

Nominal input min load (Hi) 33,6 42 50,4 58,8 kW

Nominal ouput max load 80-60 °C 163,6 204,5 245,4 282,5 kW

Nominal output min load 80-60°C 32,6 40,7 48,9 57 kW

Efficiency max load 80-60 °C (Hi) 97,4 97,4 97,4 98,4 %

Efficiency min load 80-60 °C (Hi) 97 97 97 97 %

Efficiency max load 50-30 °C (Hi) 102,8 102,8 102,8 103,9 %

Efficiency 30 % load 30 °C (return) (Hi) 107,5 107,5 107,5 107,5 %

Flue-gas

Temperature flue-gas max load 80-60 °C 70-75 70-75 70-75 70-75 °C

Temperature flue-gas min load 80-60 °C 65-70 65-70 65-70 65-70 °C

Mass-flow flue-gases at max load G25 275 343 412 474 m3/h

Mass-flow flue-gases at min load G25 55 69 83 96 m3/h

Maximum flue-resistance 150 150 150 150 Pa

Emission CO (n=1) 38 39 37 35 ppm

Emission NOx (n=1) 29 29 29 29 ppm

Types B23,C(11)3, C13,C33,C53,C63 yes yes yes yes

Gas

Also see 7.1 20,2 25,2 30,3 34,9 m3/h

Gas flow max load G25 4,04 5,05 6,05 7,06 m3/h

Gas flow min load G25 19,75 24,65 29,6 34,05 m3/h

Gas flow max load G25.3 3,95 4,93 5,92 6,9 m3/h

Gas flow min load G25.3 17,4 21,8 26,2 30,2 m3/h

Gas flow max load G20 3,49 4,36 5,92 6,1 m3/h

Gas flow min load G20 9,3 9,3 9,3 9,3 %

CO2 content max load G25/G20/G25.3 9,1 9,1 9,1 9,1 %

CO2 content min load G25/G20/G25.3 3,90 +0,10-0,30 3,90 +0,10-0,30 3,90 +0,10-0,30 3,90 +0,10-0,30 %

O2 content max load G25 4,30 +0,35-0,20 4,30 +0,35-0,20 4,30 +0,35-0,20 4,30 +0,35-0,20 %

O2 content min load G25 3,95 +0,10-0,35 3,95 +0,10-0,35 3,95 +0,10-0,35 3,95 +0,10-0,35 %

O2 content max load G25.3 4,35 +0,35-0,25 4,35 +0,35-0,25 4,35 +0,35-0,25 4,35 +0,35-0,25 %

O2 content min load G25.3 4,25 +0,10-0,35 4,25 +0,10-0,35 4,25 +0,10-0,35 4,25 +0,10-0,35 %

O2 content max load G20 4,60 +0,40-0,20 4,60 +0,40-0,20 4,60 +0,40-0,20 4,60 +0,40-0,20 %

O2 content min load G20

Maximum flow temperature 85 85 85 85 °C

Content heat-exchanger (without manifolds) 16,9 21,3 24,7 30,2 ltr

Working pressure (PMS) 0,8/6 0,8/6 0,8/6 0,8/6 Bar

Hydraulic resistance 90 96 99 103 mbar

(DT 20 nominal flow at full load 80-60 °C)

Maximum DT max load/min load 25/35 25/35 25/35 25/35 °C

Maximum water flow 14,1 17,6 21,1 24,3 m3/h

Weight

Mass heat-exchanger* 82 99 116 133 kg

Total mass Alutherm boiler 193 210 227 244 kg

Sizes of casing

Width 600 600 600 600 mm

Depth 1281 1281 1281 1281 mm

Height 1226 1226 1226 1226 mm

Electrical

Protection 00B 00B 00B 00B IP

Electrical voltage/frequency 230/50 230/50 230/50 230/50 V/Hz

Standby power consumption* 5 5 5 5 W

Maximum power consumption* 1150 1150 1150 1150 W

Fuse 5 5 5 5 A

* as coming from factory without extra devices connected