PTAC

PWHK01G70

WIRE

HARNESS

KIT

INSTALLATION

INSTRUCTIONS

Attention Installing Personnel

As

a professional installer, you have

an

obligation

to

know the

product betterthan the customer. This includes all safety precau-

tions and related items.

Prior

to

actual installation, thoroughly familiarize yourself with_

this Instruction Manual.

Pay

special attention

to

all safety warn-

ings. Often during installation

or

repair,

it

is

possible

to

place

yourself in a position which

is

more hazardous than when

the

unit

is

in

operation.

Remerrber,

it

is

your responsibility

to

install

the

product safely

and

:o

know

it

well enough

to

be able

to

instruct a customer

in

its

safe

use.

Safety

is

a

matter

of

common

sense

...

a

matter

of

thinking before

acting.

Most

dealers

have

a

list

of

specific

good

safety

practices

..

.follow them.

The. precautions listed in this Installation Manual are intended

as

supplemental

to

existing practices. However,

if

there

is

a direct

conflict between existing practices and thecontent

of

this manual,

the

precautions listed here take precedence.

AwARNING

-~--·~·-

-·-

-

~AGE-

D1scoNNECT

ALL

POWER

BEFORE

SERVICING

OR

INSTALLING

THIS

UNIT.

MULTIPLE

POWER

SOURCE

BE

PRESENT.

FAILURE

TO

DO

SO

MAY

CAUSE

PROPERTY

DAMAGE,

PERSONAL

INJURY

OR

DEATH.

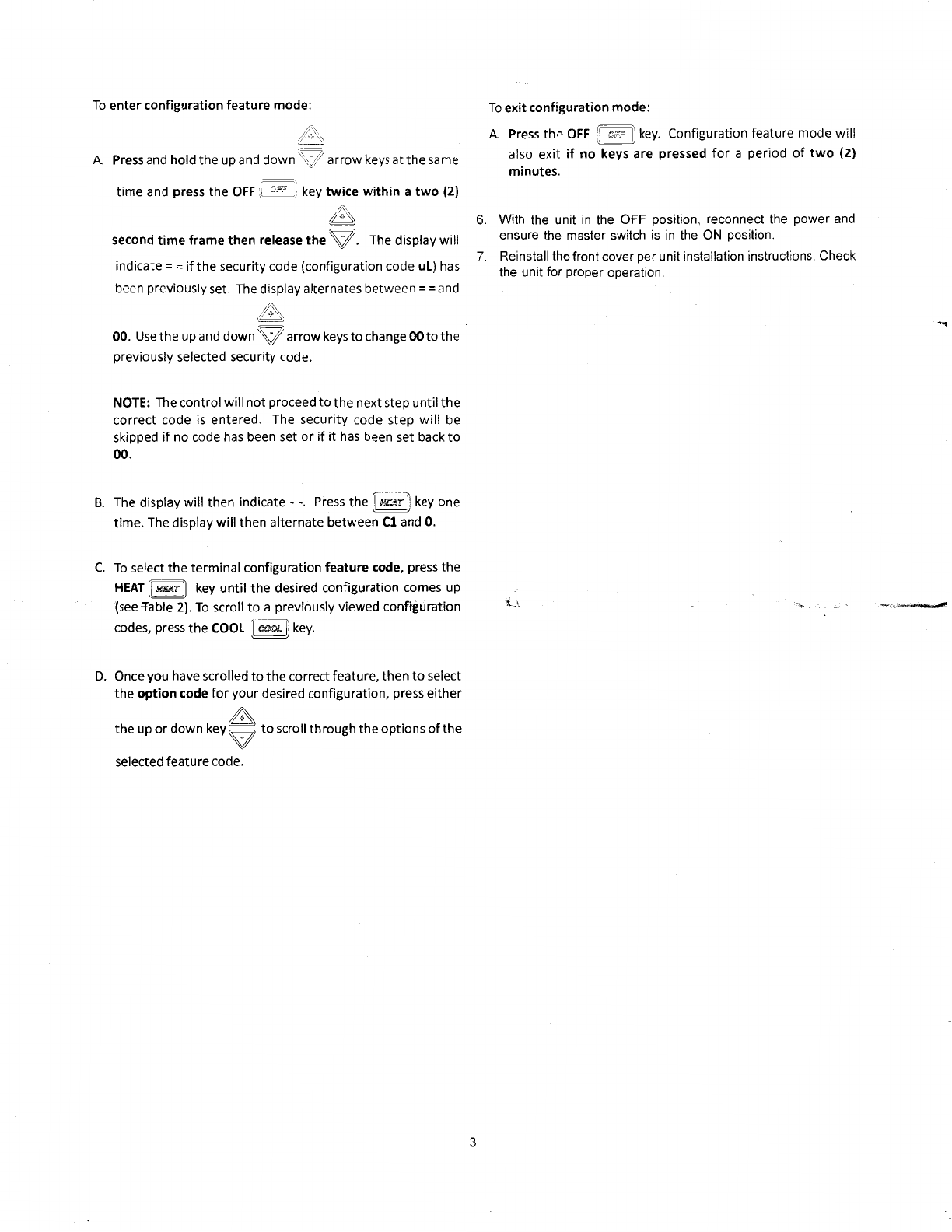

Description

The

PTAC

Wire Harness kit provides connection from

the

10-pin

terminal strip on

the

PTAC

M70 control board

to

the

following

board features:

DoorSwitch*

Motion

Sensor*

Emergency Hydronic

Heat**

Load Shedding**

Front Desk

Control**

Remote

Thermostat*

General Purpose Alarm

Input**

The

kit includes a 10-pin female housing

with

10

jumper

wires

and

wire nuts. The installation and servicing

of

this equipment

should be performed by qualified, experienced technicians.

*Contact yoursoles personfor propermanufacturer-approvedde-

vices and wiring instructions.

**if

other

than a "dry switch"is used

in

connecting

these

features,

consultmanufacturerbeforeproceeding.

u !\

P\

L.)

u

/

-.

B (BLUE)

/

//

;:;GRAY)

7°'),,

+-</•,

,,,:P

/

W:JWHITE)

/ R

(RED)

,,,./'

GH(VIOLET) /

I.

,B

,

INl(ORANGE)

-

,,,:P

/

,,/

f Y(YELLOW)

D

GL

(GREEN) ,

~

COM(BROWN)

/

HIGH VOLTAGE

AwARNING

~

DISCONNECT

ALL

POWER BEFORE SERVICING OR

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES

MA

fi

BE

PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

.

DUE

TO

POLICY

OF

CONTINUAL

PRODUCT

IMPROVEMENT,

THE

RIGHT

IS

RESERVED

TO

CHANGE

SPECIFICATIONS

AND

DESIGN

WITHOUT

NOTICE.

10-815

5/2014 :A.,.,.,..

is

a reglotered

trademark

of

Maytag

C~cporation o• ,ts

related

companies

and

is

used

under

!icense

to

Goodman

Company,

L.P_.

!,-,:o,..;ston,

TX. Ail

r1g~,ts

reserved.

5151 San Felipe. Suite 500 • Houston. TX 77056 •

11

H'H.c1111mw-p1ac.,om

©

2014

Goodman

Company.

L.P.