L17401-CL06JEN-E2-S02, REV. C INTRODUCTION TO TROUBLESHOOTING

Copyright © 2019 Amatrol, Inc.

S02-5

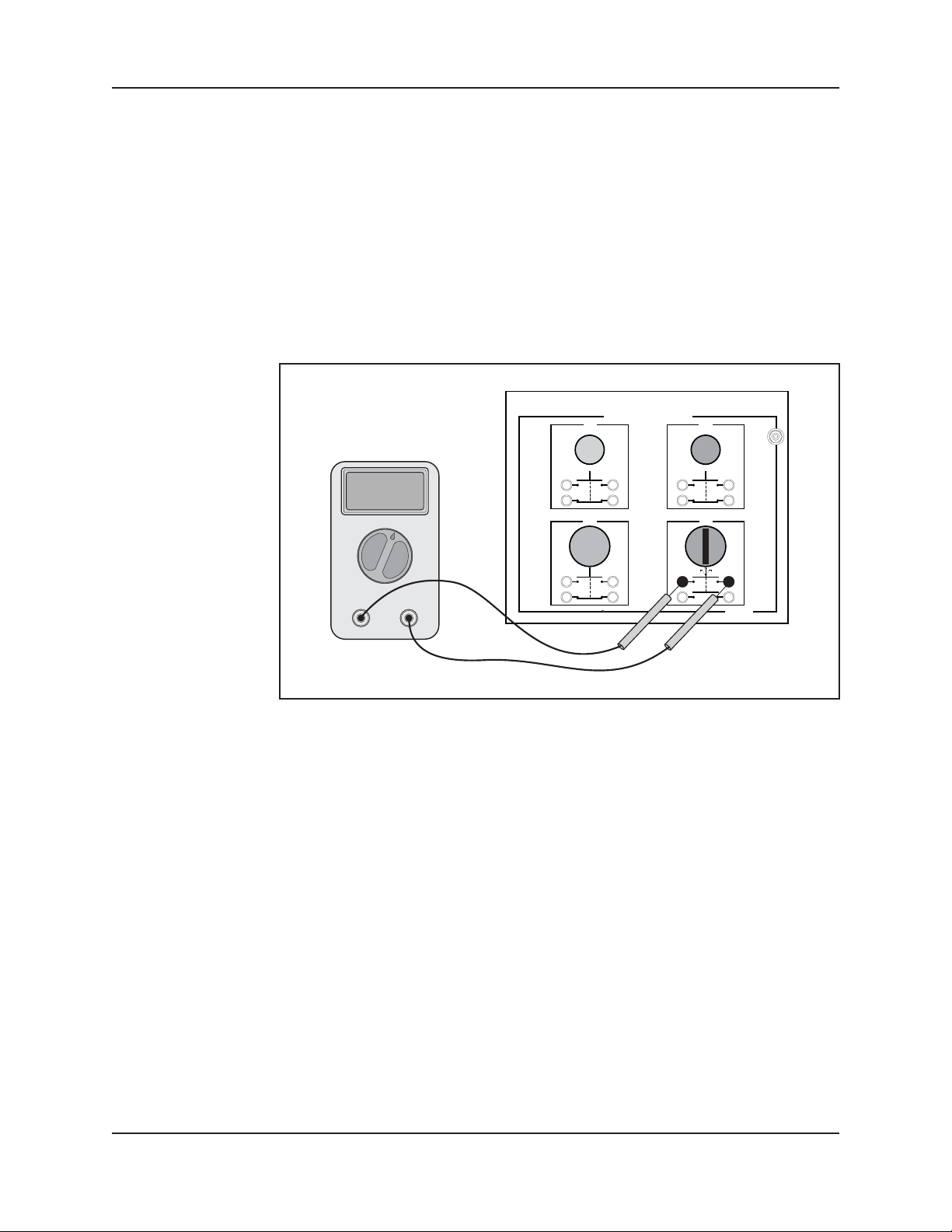

SKILL 2 TEST A MANUAL SWITCH

B. If you are using the FaultPro Troubleshooting System, turn on the system.

C. Start up the FaultPro software and login using your ID number and

password.

D. If necessary, open the Class folder by clicking the +to the left of the class

name.

E. Open the LAP 6: Introduction to Troubleshooting option.

F. Select the Skill 2: Test a Manual Switch option.

G. Click the Single Fault Mode button.

The FaultPro software will open the Single Fault Mode window.

H. Type 6in the Enter Fault field.

I. Press the Enter key or click to activate the fault.

Fault 6 is now active. You should observe that the fault status field changes

from “No Faults Active” to “Fault 6 is Active.”

Fault 6 is a short in the N.O. contacts of PB1.

J. Repeat step 4 to test the pushbutton and record your measurements.

PB1 Resistance (not pressed) ___________________________ (Ohms)

PB1 Resistance (pressed)_______________________________ (Ohms)

Component Status _________________________________ (Good/Bad)

This time you should find that the multimeter measures zero resistance

in both conditions. This means that there is a short in the contacts. The

component is bad.

K. Click the Clear Fault button to clear the fault or remove the fault plug.

With the FaultPro software, the fault will clear and the fault status field

should change to “Fault 6 is cleared.”

If you are using manual fault insertion, remove the short plug from

terminal 6 and replace it with the standard jumper plug.

L. Repeat the pushbutton test in step 4.

PB1 Resistance (not pressed) ___________________________ (Ohms)

PB1 Resistance (pressed) ______________________________ (Ohms)

Component Status _________________________________ (Good/Bad)

The resistance should change this time when the pushbutton is pressed.

This means it is good again.

Now proceed to the next substep to test an open type fault in N.O. contacts.

M. If you are using manual fault insertion, locate the open fault plug and plug

it into station fault terminal 7. Then, go to substep P. If you are using the

FaultPro software, continue with substep N.

N. Type 7to insert fault 7 in the Enter Fault field.