2 Safety instructions

The installation and commissioning as well as the connection of electrical components require

technical knowledge commensurate with a recognised vocational qualification as a fitter for

plumbing, heating and air conditioning technology, or a profession requiring a comparable level of

knowledge [specialist].

The following must be observed during installation and commissioning:

●relevant local and national regulations

●accident prevention regulations of the professional association

●instructions and safety instructions mentioned in these instructions

CAUTION

Personal injury and damage to property!

The product must only be used in heating circuits filled with heating water according

to VDI 2035 / Ö-Norm H 5195-1.

►The product must not be used in drinking water applications.

NOTICE

Material damage due to mineral oils!

Mineral oil products cause lasting damage to seals made of EPDM, whereby the sealant properties

are lost. We do not assume liability nor provide warranty for damage to property resulting from

sealants damaged in this way.

►It is imperative to prevent the EPDM sealing elements from making contact with substances

containing mineral oils.

►Use a silicone- or polyalkylene-based lubricant free of mineral oil such as Unisilikon L250L

and Syntheso Glep 1 from Klüber or a silicone spray.

NOTICE

Damage to property!

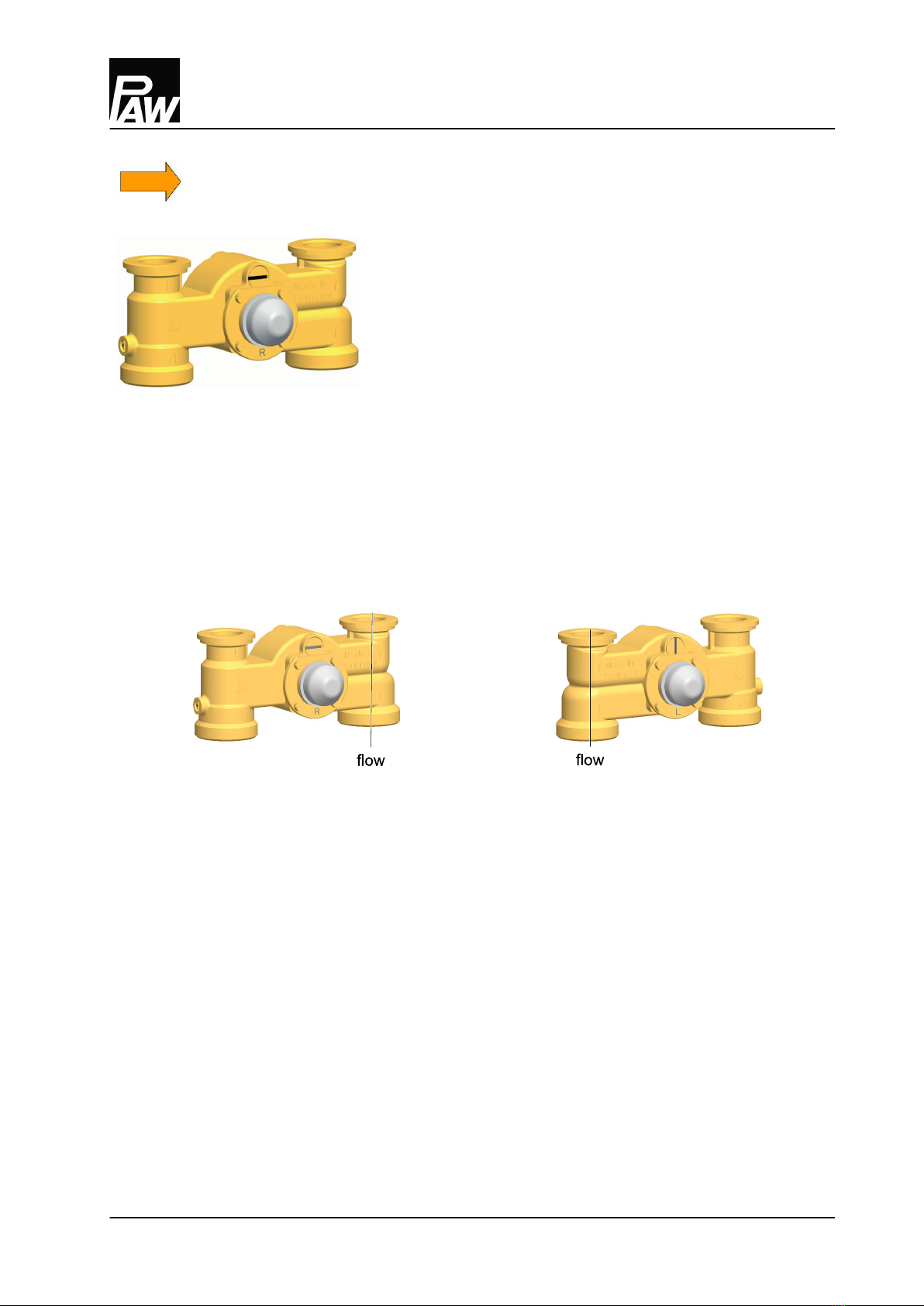

►It is mandatory to mount the contact thermostat at the flow.

Only in this way, it prevents the HeatBloC® from overheating.

2 Safety instructions

4 9936073x-mub-en - V04 08/2023