Page

4.3.1 Programming working width ..............…….... 4 - 3

4.3.2 Checking programmed working width .....….. 4 - 4

4.3.3 Determining seed drill factor .................……… 4 - 4

4.3.4 Calculating seed drill factor ..................………. 4 - 7

4.3.5 Programming seed drill factor ...........……........ 4 - 9

4.3.6 Checking seed drill factor ..............…..……….. 4 - 9

5 Operation ............................................…….. 5 - 2

5.1 Hectare counter (F.2, F.7, F.8, F.9) .......…… 5 - 2

5.1.1 Displaying / clearing memory contents

HA.1 / HA.2…………………………………….. 5 - 2

5.1.2 Metering area …………………………………. 5 - 3

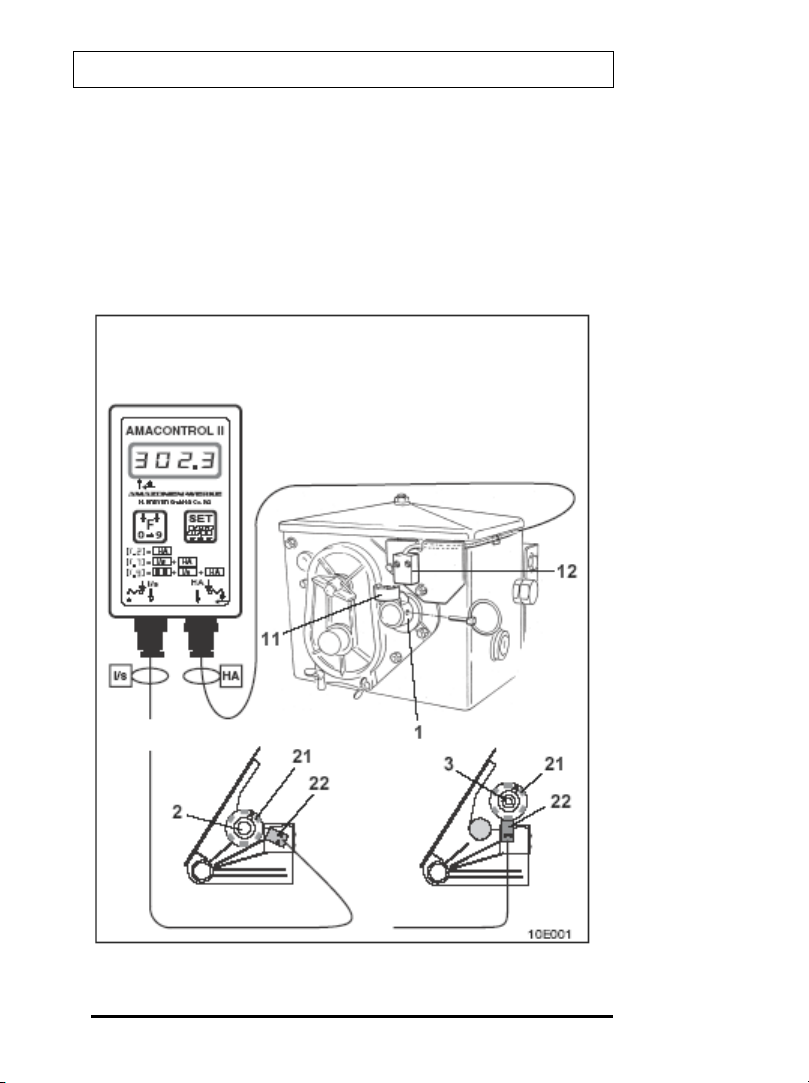

5.2 Monitoring drilling shaft (F.7, F.8) ............. 5 - 4

5.2.1 Alarm ................................................…......... 5 - 4

5.2.2 Setting alarm delay time.................................. 5 - 5

5.3 Displaying switching position of the

tramline switching mechanism

(F.8, F.9) ..............................……………….... 5 - 6

5.3.1 Setting switching time and number of

programs prior to commencing work ………. 5 - 6

5.3.2 Commencing work ........................................ 5 - 7

5.3.3 During operation ........................................... 5 - 10

5.4 Monitoring lay shaft of seeding wheel

tramline switching mechanism (F.9) .......... 5 - 11

5.4.1 No alarm ..............................................……. 5 - 11

5.4.2 Alarm ...................................................…..... 5 - 11

5.4.3 Alarm delay time ............................................. 5 - 11

Contents