5

IMPORTANT PROCEDURES

FOR THE AMERICAN ACCESS SYSTEM

Please take note that your ramp system may have several different leg types and sizes, ramp sizes and even plat-

form sizes.

INSTALL NOTES:

The “XM” system uses 2 styles of leg supports.

• The ramps use a UCHANNEL style

• The platforms use a SQUARE TUBE design

MOST residential ramp systems will be 36” wide with 2’, 3’, 4’, 5’, 6’, and 8’ long ramp sections.

When a ramp is connected to or pushed against a platform, U-legs and a bridge plate must be installed

Please refer to installation manual for details.

We highly recommend that you lay out your parts until you become more comfortable and familiar with them.

Please evaluate and take notice of the components you have for the layout design you have purchased. If you

are still unclear and need assistance after your evaluation, please call customer service and we will be glad to

help.

888-790-9269 Mon-Fri 8am - 5pm Central time

Lay out all your leg supports so you can identify tallest to shortest. This will allow you to install your modular

ramp at a quicker pace.

Important Note: There may be times that you have a tall starting height, but because the first ramp or

platform begins on a porch or over a set of steps, you will be using shorter legs at that point, then once

you clear these obstacles, you will begin using the taller legs.

Your ramp system will also come with handrail loops. Loops are used when the ramp terminates on platforms or

at the end of the ramp.

Once you have laid out your components and identified them, you may begin your installation.

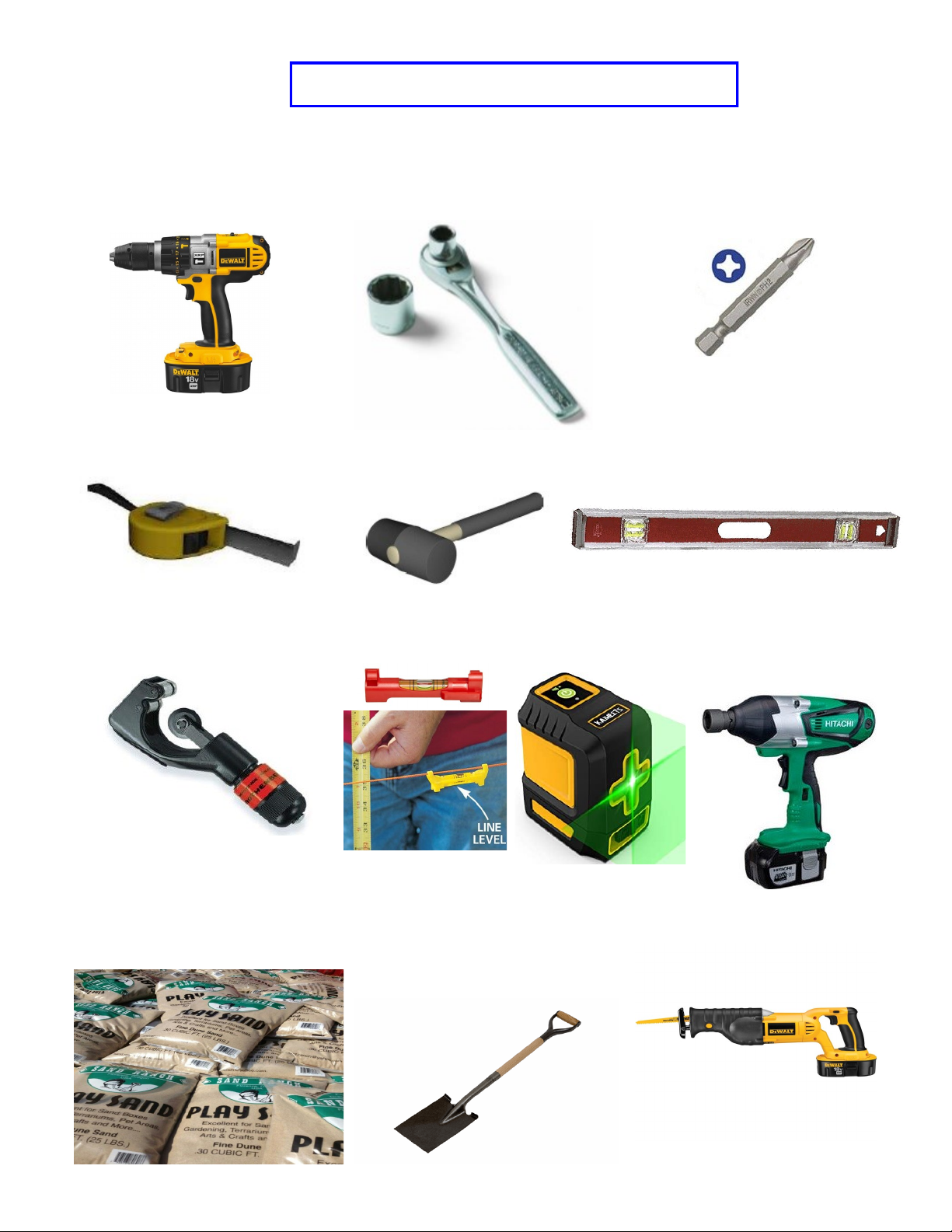

MAIN HARDWARE FOR THE AMERICAN ACCESS “ XM “ SYSTEM:

The hardware used on the “XM” system is 3/8” Zinc Grade 5 requiring a 9/16” socket:

• RHPN Ramp Hardware Packet

43/8” 16 - 1” Carriage Bolt for support U-Legs

83/8” 16 - 2 1/4” Carriage Bolt for Handrails

12 3/8” 16 - Flange Nut

• PHP Platform Hardware Packet

33/8” -16 - 4.5” SS Bolt

43/8” - 16 - 1/2” SS Bolt

33/8” SS nuts

63/8” SS washer

11 #14 Tek Screw

16 Black Plugs for post holes

2Rail post stabilizer (u channel)