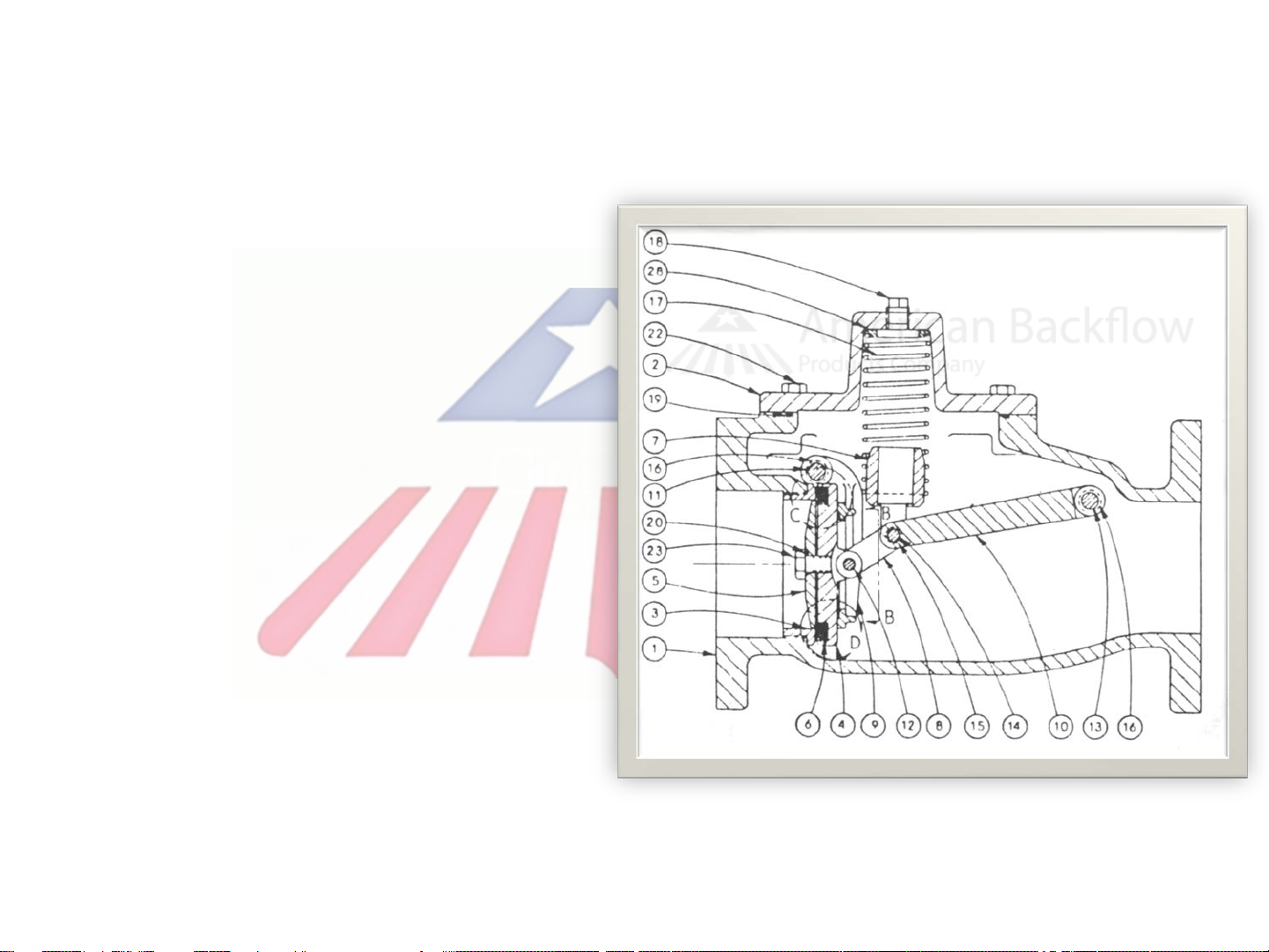

Check Cover Removal

The check covers are secured by bolts and sealed by an o-ring.

2” through 6” sizes remove all but two cover bolts, leaving two bolts 180

degrees apart. Press down on the cover while removing the last two

bolts to prevent the cover from being forcibly ejected by the spring.

8” and 10 sizes, it is suggested that all-thread rod and nuts (jack screws)

be used when removing or replacing the covers. The 8” size uses two

5/8”-11 all-thread approximately 8” long. The 10” size uses two ¾” -10

approximately 8” long. Remove two cover bolts on opposite sides of the

cover, and install all-thread rod. Install and tighten nuts down to cover.

Remove remaining cover bolts. Simultaneously, back the jack screw nuts

off until the spring tension is completely released. Remove the cover.