4

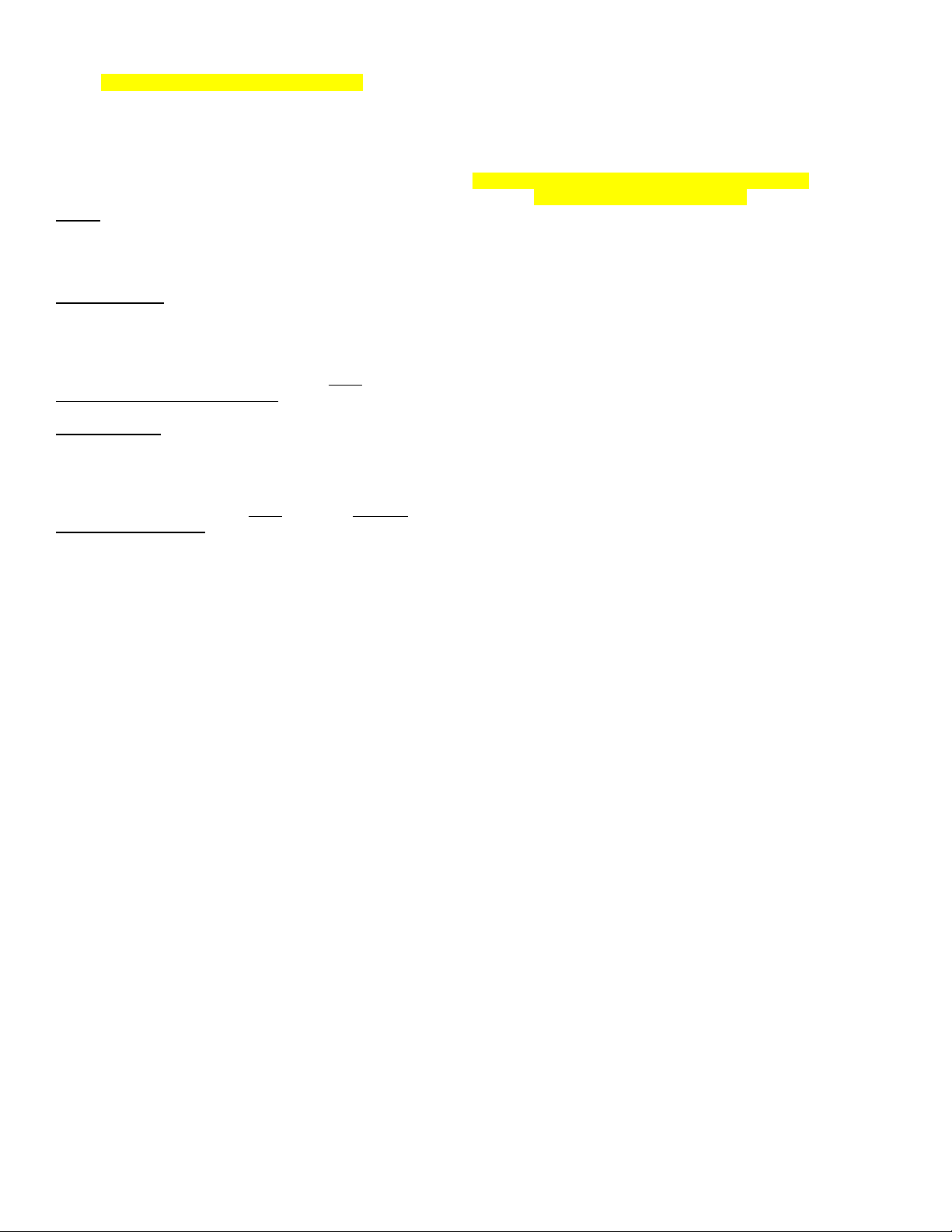

KEYPAD HIDDEN COUNTER FEATURE

The remote keypad has a hidden resettable counter kept on the

keypad itself. To access this counter hold the keypad and

press the #7-#4-#1 keys SIMULTANEOUSLY. The number

that appears is your meter count. To clear the counter, press

the #9-#6-#3 keys SIMULTANEOUSLY. The meter count

has now been reset to zero.

NOTE: THIS COUNTER IS NOT THE METER COUNTER

THAT IS NON-RESETTABLE LOCATED ON THE LOGIC

BOARD INSIDE THE MACHINE! Please open the door to

access that counter.

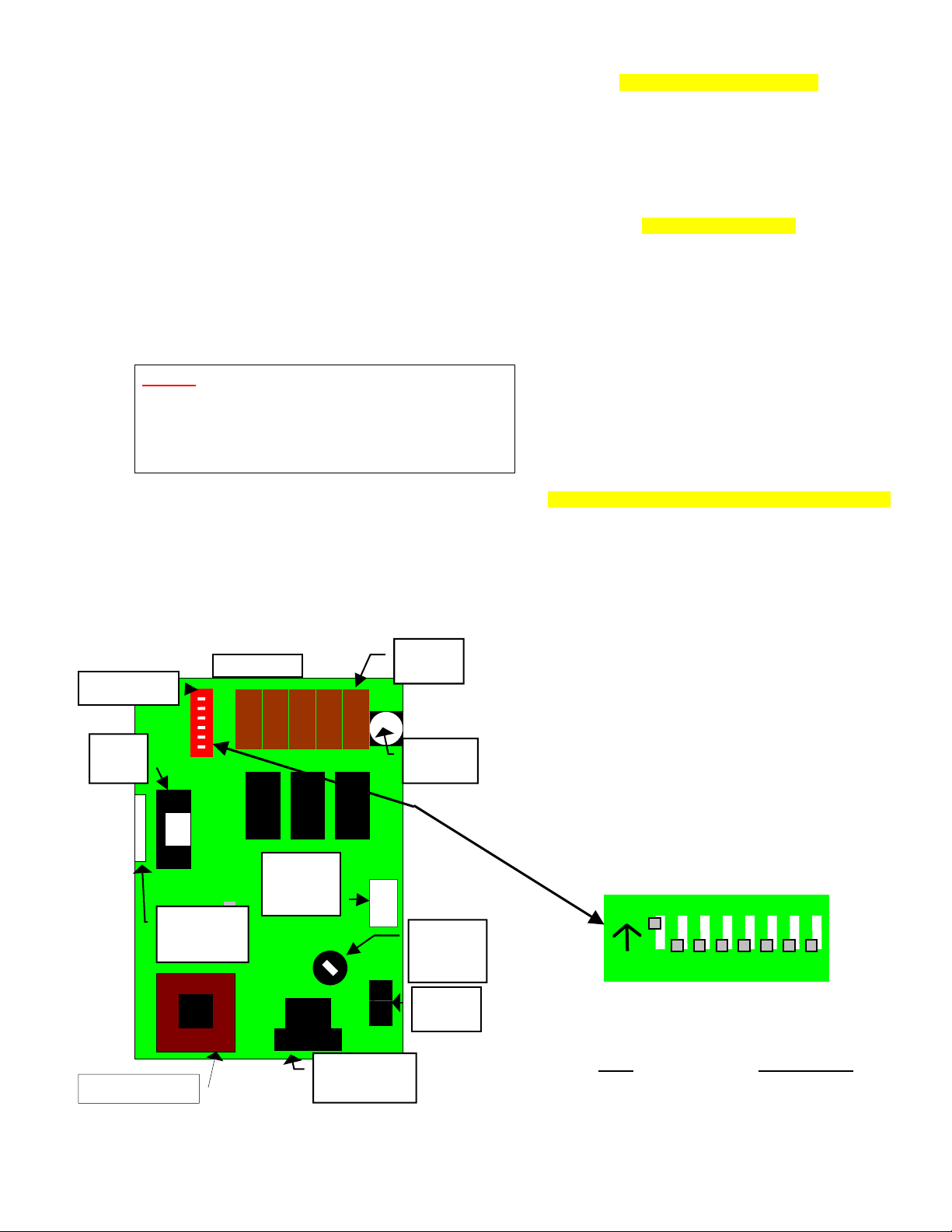

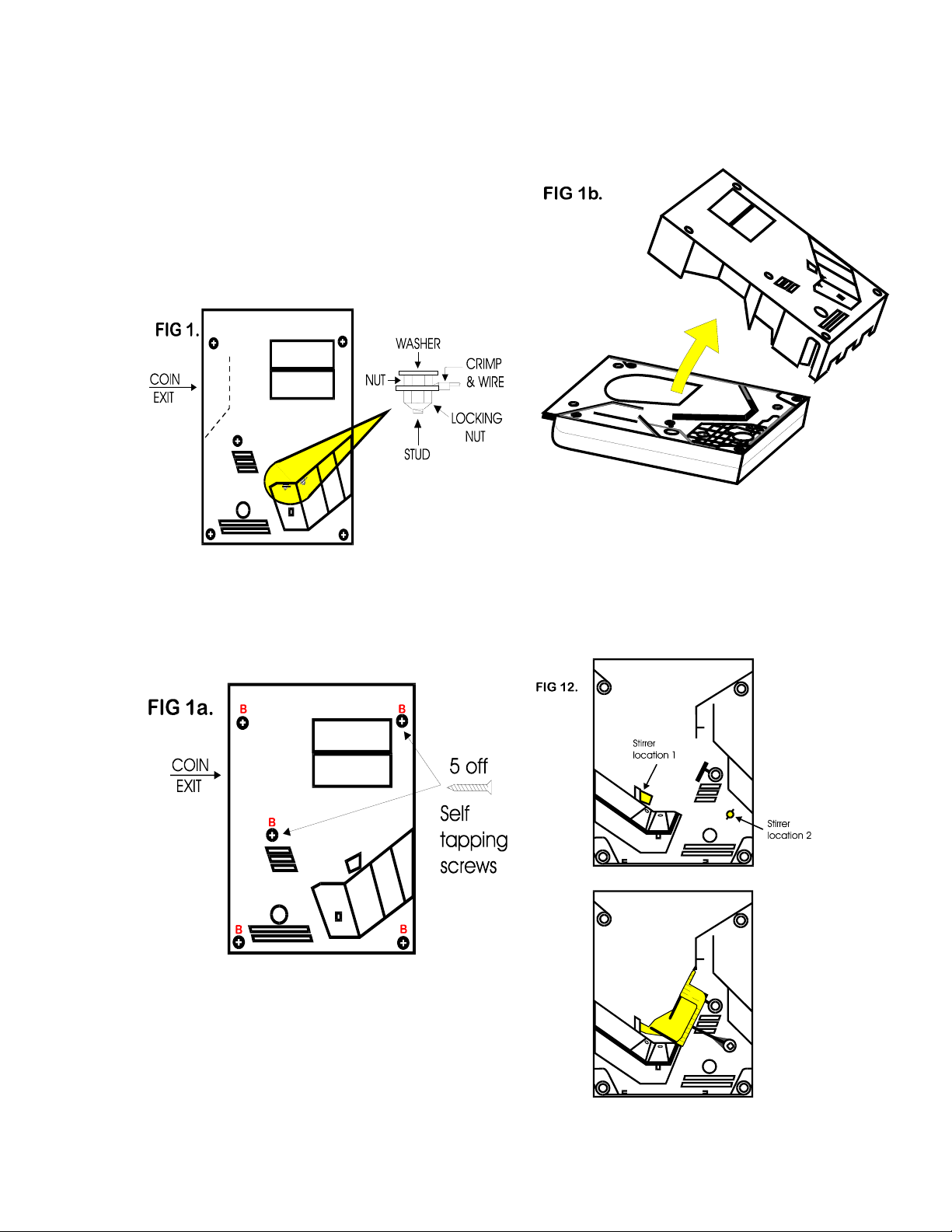

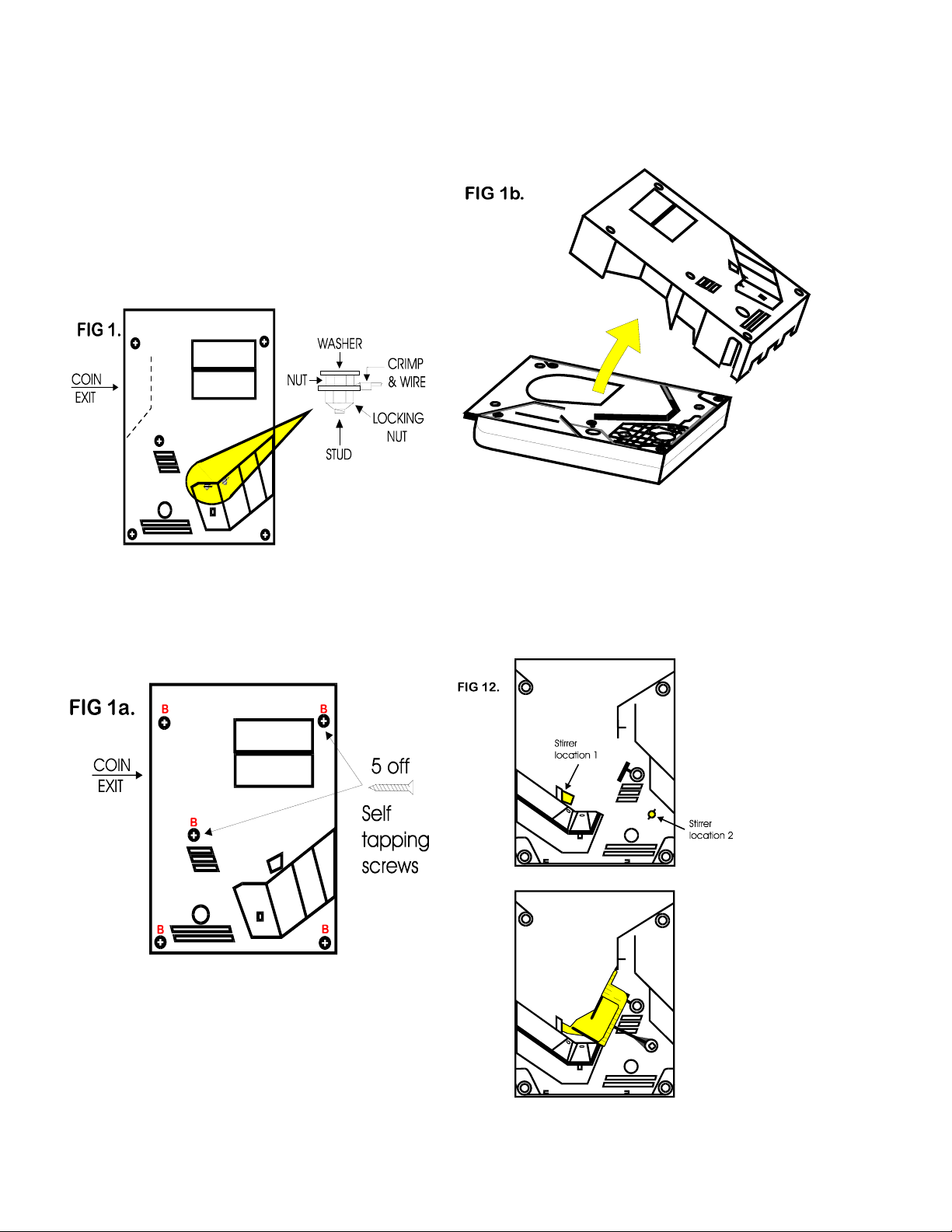

FUSE

High voltage fuse: This is the primary transformer AC fuse

for the main logic board and the validator. Any direct short of

the Transformer or validator will cause this fuse to blow.

Replace this fuse with a 2-½ amp AS fuse only.

REPLACING THIS FUSE WITH ANYTHING OTHER

THAN A 2 ½ AMP “AS” MAY RESULT IN A FIRE OR AN

UNSAFE WORKING CONDITION!! (See fig. 1 for

location of this fuse.)

Low voltage fuse: This is the secondary transformer fuse for

the 5 - 28 vdc sections of the main logic board and hopper. It

is located to the left of the transformer. (See fig. 1) Replace

this fuse with a 2-½ amp AS fuse only. REPLACING THIS

FUSE WITH ANYTHING OTHER THAN A 2 ½ AMP

“AS” MAY RESULT IN A FIRE OR AN UNSAFE

WORKING CONDITION!!

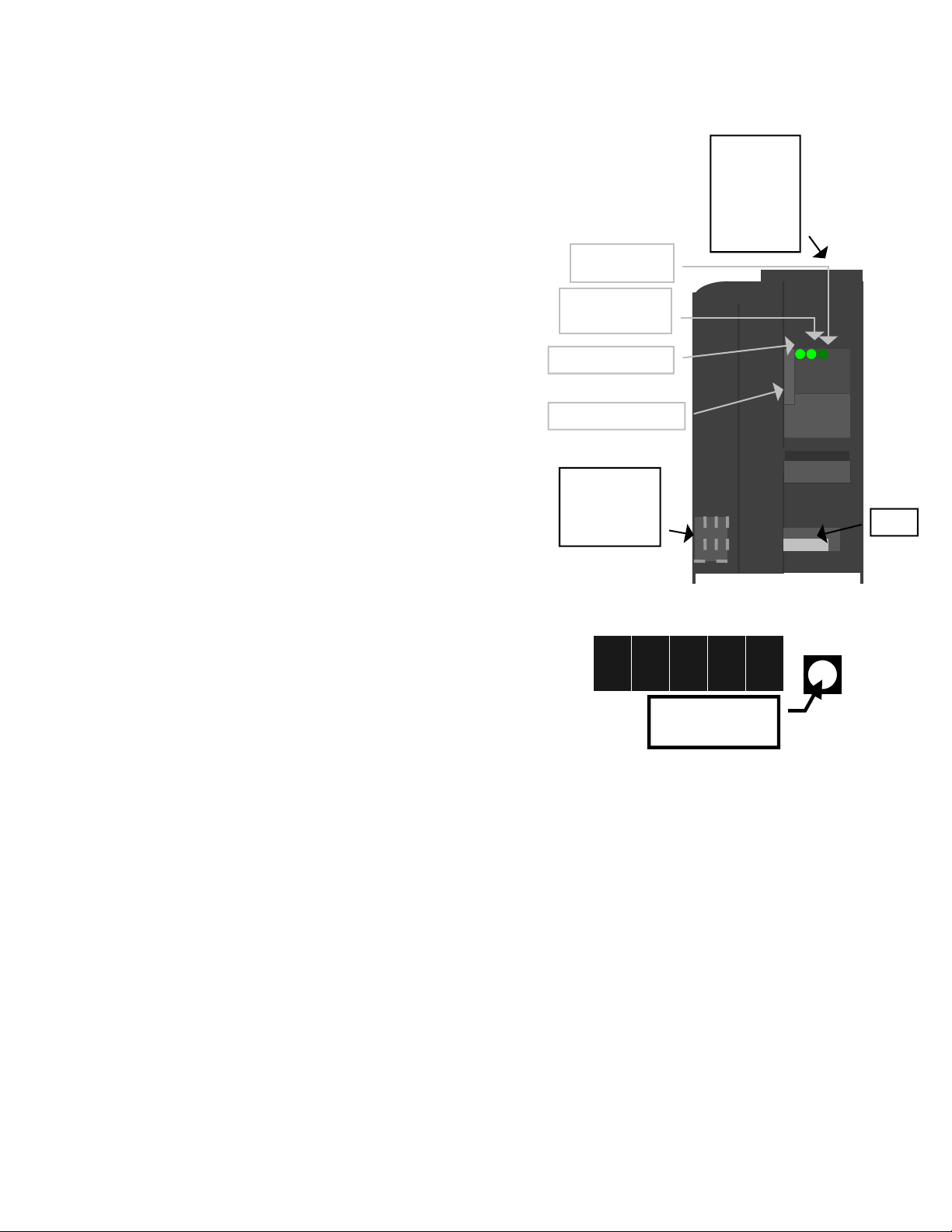

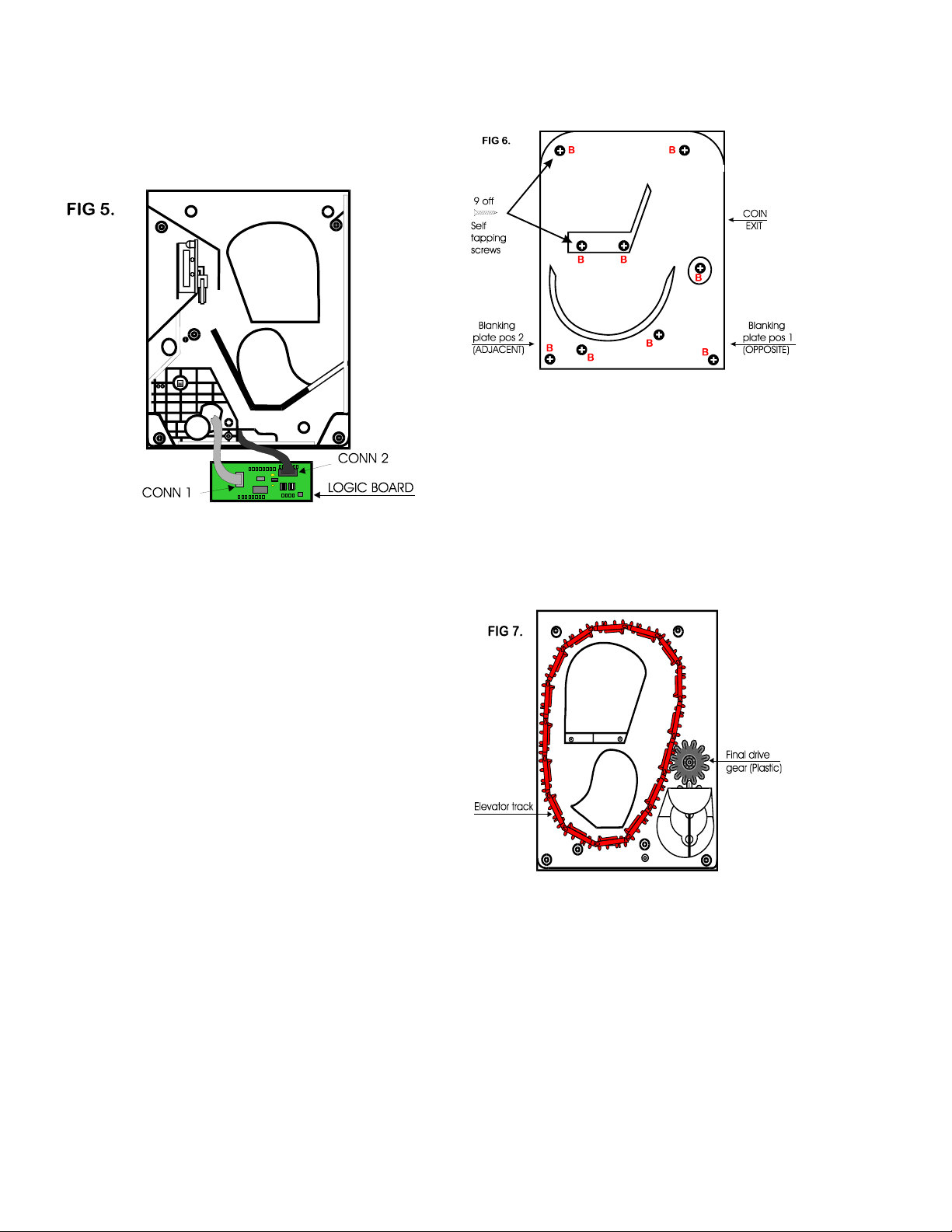

Functional Description of the Series AC250Changer

To follow along with this walk-through of your changer, fill

the hopper with coins and turn the changer on.

1. When power is applied the out-of-service LED flashes

then goes out. The green LED on the main logic board

comes on steady, and the red LED on the main logic

board will light then go off then flicker on once per

second in the standby mode.

2. During the power-up mode the main logic board relay

clicks twice enabling power (120vac). When this relay is

not enabled it routes 12vdc ground to the out-of-service

LED. Without any power to the validator the changer

cannot accept bills. Since we are not in the error mode,

the red LED on the validator logic board is on steady.

3. When the “Enter” button on the keypad is pressed it

grounds the 5vdc lines causing a pulse along the yellow

and blue validator harness wires to pins 5 and 15 of the

main logic board. Each pulse stands for the number on

the keypad display, i.e. 5 means the ground line was

pulsed 5 times.

4. The 5vdc pulse then travels from pins 5 and 15 to the

EPROM chip (MONO A-31) pin #25. The EPROM

sends a 12vdc pulse to the meter chip (U5) out pins #21

& 22 (one pulse per denomination validated ).The

EPROM also multiplies the ground pulse by the DIP

switch settings (The EPROM reads the DIP switch

settings during the power up mode and stores them into

memory.)

5. The EPROM then sends the hopper pulses out pin #23 to

pins 6 and 7 of the red 12-pin hopper plug. These pulses

travel through the purple and brown wires of the hopper

wire harness to the hopper pins 8 and 12.

6. The hopper turns itself on with the first hopper pulse.

The hopper counts the hopper pulses sent from the

EPROM chip on IN3 (pin 12) while dispensing the coins

at the same time. When the amount of hopper pulses in

equals the coins dispensed through the coin counting

optical sensor the hopper turns itself off.

7. The Changer returns to the standby mode with the red

LED flashing once per second until another bill is

inserted.

NOTE: THE METER ON THE MAIN LOGIC BOARD

CANNOT BE RESET TO ZERO!!!

Functional Descriptions of Out-of-Service Conditions

Out-of-Service conditions occur for the AC250 changer for

the following reasons; low coins, hopper fault error, validator

fault, or a blown fuse.

1. Blown Fuse: an AC power spike in line voltage or a bad

transformer on the main logic board can cause A blown

fuse on the main logic board. If either fuse blows the

indication is the green LED on the main logic board will

not light.

A. Replace the fuse. If the green LED now lights then

there was a spike.

B. If it does not and the fuse blows again the power

transformer is shorted. To test the transformer use a

voltmeter set for ohms and measure across the

primary (40ohms) and the secondary (1.5ohms).

2. Hopper Fault: A hopper fault can either be a jammed

hopper, a blocked coin counting optic or a bad hopper

logic board.

A. Indications for a jammed hopper are the changer

accepts bills, the meter counts up, but nothing or

not enough coins are paid out.

1. After 2 minutes the EPROM shuts off the

validator if the coins are not paid out correctly.

The “Empty” LED will flash once per second.

2. At this point the three options open are to

attempt repair on your own, call your

distributor, or return the hopper to American

Changer.

B. Indications for a blocked coin optic or bad hopper

logic board are the out-of-service LED on the

outside of the changer is lit and the red LED on the

main logic board is lit and flickers off once per

second.

1. If two of the 3 green LED’s on hopper logic

board are lit then the hopper logic board is

bad.

2. If there is a coin or foreign object caught in

the coin exit window LED’s #1 and #3 will

be lit on the hopper logic board instead of

LED’s #1 and #2.

a. Take off the side of the hopper with 5

Philips screws. Pull up on the exit

window logic board and look for the

jammed item.

b. Ensure you have the pins aligned before

reconnecting logic board.

3. Low Coins: The low coin condition is probably the most

common fault. The EPROM on the main logic board is

constantly checking for low coins in the hopper. This is

done with a low current 5vdc signal on pin #3 of the

hopper output connector. The voltage then travels down

the hopper wire harness on the white wire to pin #7 of

hopper plug. The signal is applied to one of the gold low

contact plates at the bottom of the hopper. The 5v travels

through the coins through the other contact gold plate to