Remove the connector cover.

(Do not lose the cover.)

Expansion

connector

LA-A1AW

LB-A1AW DP-DN 20mA ①

■Current consumption

■Conditions for extension

common

LA-A1AW

LB-A1AW 16 points ③

16 points ②

■I/O points

4-20mA

4-20mA

1-5V

4-20mA

4-20mA

Other conditions:

-L*A1AW 5/12-

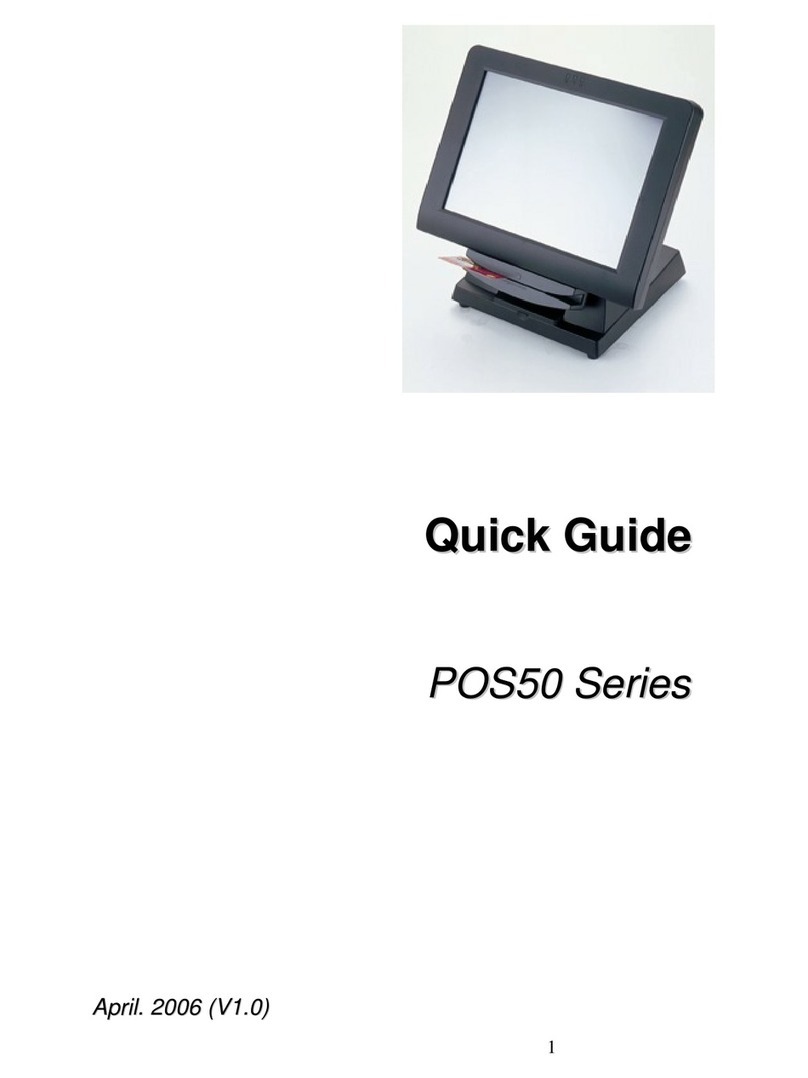

[Installation]

[Removal]

[Installation Location]

D

A

A

Upper side

Upper side

D

B

G

Base Extension

[Precautions when Using]

C

A

The installation and removal methods are the same for both the base

unit and the extension unit.

Put the moving claw on the A side on the DIN rail.

Push down on xed latch D on the opposite side until you hear a click.

Push this product in direction B, removing xed latch D from the DIN rail.

Lift up straight in direction G, lifting and removing the product.

- Location where this product is not directly subject to vibration or shock

- Location where this product is not directly exposed to dust

- Location where this product is not directly exposed to a conductor, such as

waste metal or sputter

- Location without condensation

- Location where the atmosphere is free of corrosive gas, ammable gas, and

sulfur

- Location far from high-voltage or high-current cables

- Location far from cables and controllers that generate servo, inverter, or other

high-frequency noise

If connecting this unit to a transmission line or expanding the base unit with an

extension unit, do so with supply of the transmission signal stopped.

Performing connections while wires are live may cause the unit to detect

chattering as an error upon connection and stop.

If installing vertically, bring the

movable latch below the DIN rail.

[Expansion]

An extension unit or power supply unit can be extended to a base unit

for this analog input unit.

Remove the connector cover of the base unit and connect the

extension unit with a built-in extension connector. (Power supply unit

→Refer to P6)

Decide the maximum number of extended devices within the range

meeting the conditions below.

Extension

Base

Example)

(1) Considering based on the limit of I/O points

LA-A1AW: Input 16 points × 1 device ②,

LB-A1AW: Input 16 points × 7 devices ③

Maximum input points: 256 points ⑦÷ 16 points = 16

16 × 1 + 16 × 7 = 128 ≦256 points ⑦(Maximum number of input points)

(2) Reviewing based on the limit of DP-DN current consumption per block

LA-A1AW: 20 mA × 1 device ①, LB-A1AW: 20 mA × 7 devices ①

In other words, LA-A1AW: (1 device × 20 mA), LB-A1AW (7 devices × 20 mA = 140 mA)

Therefore, 20 mA +140 mA = 160 mA ≦800 mA ⑤→No problem

(3) Reviewing based on the limit of 24V-0V current consumption per block

Analog sensor: 50 mA × 8 devices ⑥⑨

In other words, analog sensor: (8 devices × 50 mA = 400 mA)

(4) Reviewing based on the limit of DP-DN current consumption per system

Eight devices consisting of LA-A1AW: 1 device and LB-A1AW: 7 devices →160 mA ①

Therefore, 400 mA ≦800 mA ⑥→No problem

Therefore, 160 mA ≦2 A ⑧→No problem

31 ④

DP-DN: 800 mA or less ⑤

24V-0V: 800 mA or less ⑥

The maximum number of extended devices in

connecting the base unit to the extension unit or

power supply unit

Total DP-DN current consumption for 1 block

(base unit + extension unit)

Input: 256 points or less ⑦

Output: 256 points or less

50 m/1.25 mm2: 2 A ⑧

(Refer to P2)

■Conditions for 1 system

Make sure the total number of I/O points of

connected devices does not exceed the maximum

transmission points per one system by master setting.

Make sure the total DP-DN consumption of

connected devices does not exceed the maximum

allowable supply current per one system.

Transmission conditions: Transmission distance (total extension), transmission distance

diameter 1.25 mm

2

, I/O 256 points respectively

Device conditions: Only 1 LA-A1AW and 7 LB-A1AW are connected.

Analog sensor 24V Current consumption 50 mA × 8 devices ⑨

Total power supply unit 24V-0V current

consumption used for 1 block above

Mixed-connection of LB-A1AW and LB-A12W is possible to

LA-A1AW. The range of each channel can be mixed.

LB-F1011 cannot be connected.