4 | AmFabSC.com American Fab of SC, LLC | Travelers Rest, SC

Important Safety

Equipment Specic Warnings

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section

at the beginning of this manual

before set up or use of this

product.

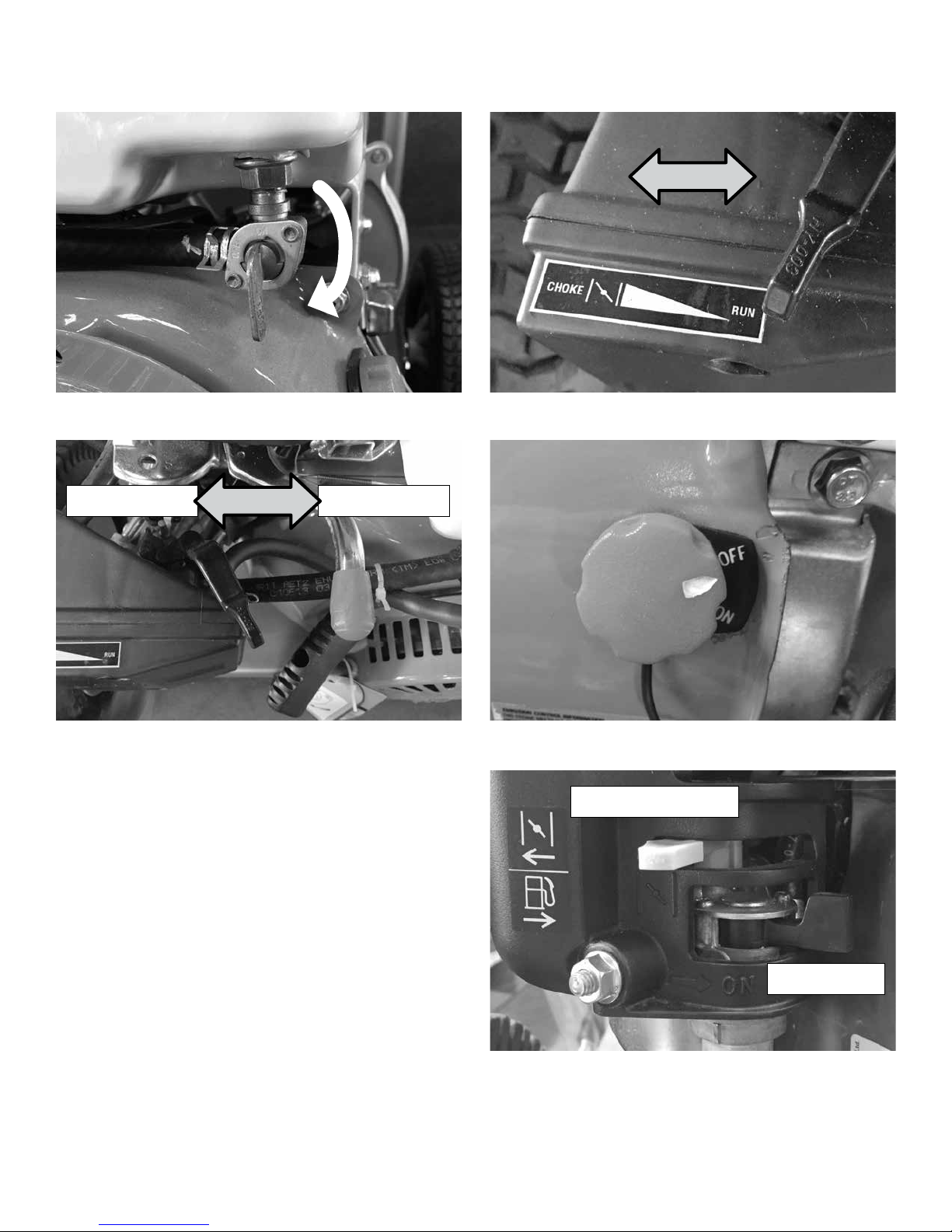

Your Pressure Washer, Model TY-4000 is a gasoline

operated device that converts residential water

pressure into extremely high pressure. The unit is

portable and mobile. The gasoline engine makes it

possible to use the unit in remote areas that are void

of electrical power if needed.

Pressure washer cleaning solvents can be mixed into

the pressurized stream to make the cleaning even

more powerful.

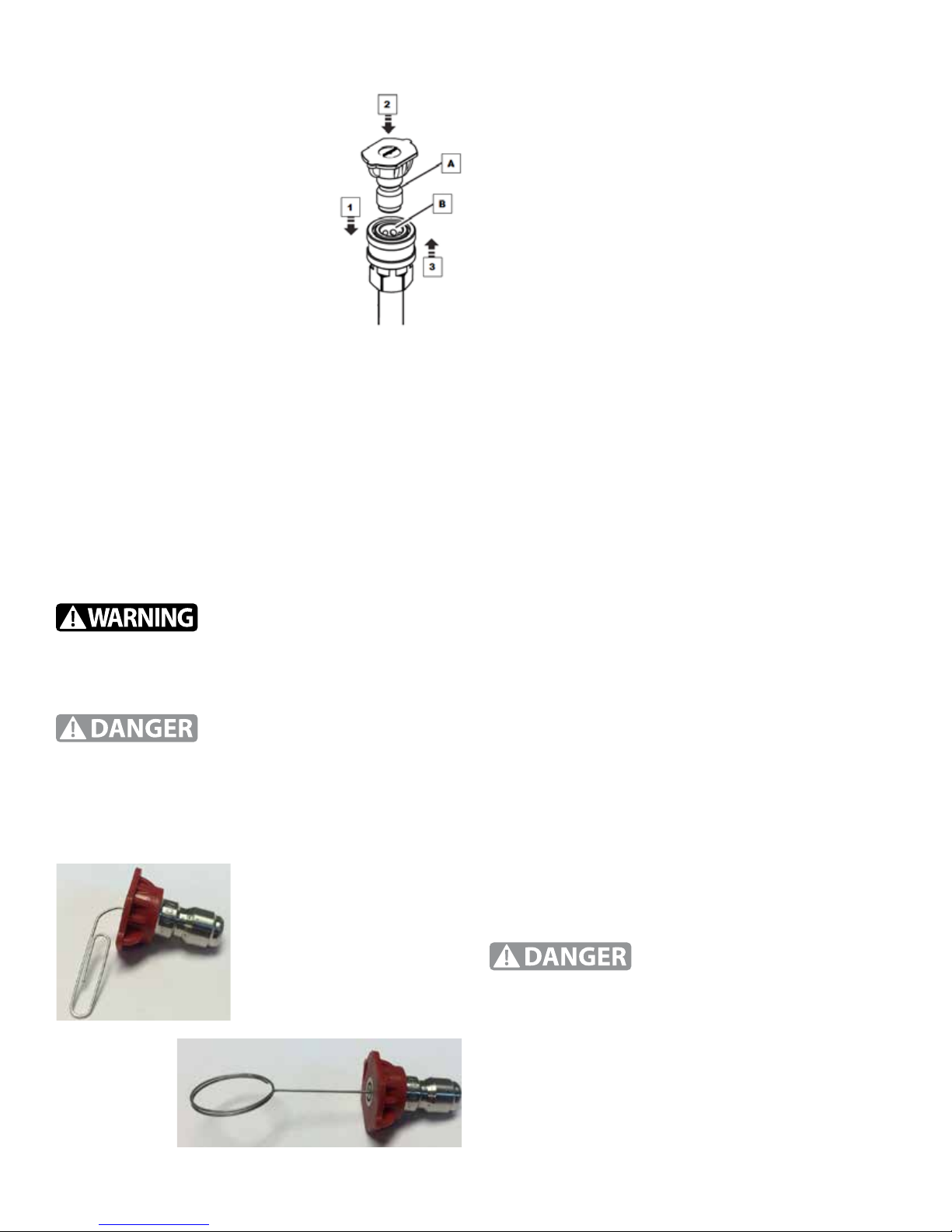

The powerful spray is capable of causing damage

to wooden surfaces, glass, automobile paint

and trim and delicate objects such as owers

or shrubs. Check the item to be cleaned before

directing the pressurized spray. Adjust the

stream to accommodate the item to be washed.

• The following safety precautions must be

observed at all times because the pressure

washer and components make up a high system.

• Follow all codes for the safe operation of this

equipment both local and federal (United States

occupational safety and health OSHA).

• Only people that are well acquainted with the

rules of safe operation should use the unit.

• Read and understand all manuals and instructions

included with the pressure washer before

attempting to use it.

• To reduce the risk of injury, keep children and

other people away. All persons involved should

wear safety glasses and be kept a safe distance

from work area.

• Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Following this

rule will reduce the risk of serious personal injury.

• Do not stand on the unit or attempt to use it as a

hand hold.

• Do not make adjustments to washer while engine

is running. This pump is designed to handle

nonvolatile, nonammable liquids and non-

corrosive liquids.

• Dress properly. Do not wear loose clothing,

gloves, neckties, or jewelry. They can get caught

and draw you into moving parts. Rubber gloves

and nonskid footwear are recommended. Also

wear protective hair covering to contain long hair.

• Hold the handle and wand securely with both

hands. Expect the trigger handle to kick back

when the trigger is pulled due to reactive forces.

Failure to hold securely can cause loss of control

and injury.

• Inspect the entire system for leakage, weaknesses,

damage or deterioration before each use.

• Do not operate the product while under

the inuence of drugs, alcohol, or any

medication.

• Replace or repair any defective parts before using.

• Check all fasteners regularly.

• Check the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire, or

string which can be thrown or become entangled

in the machine.

• Do not touch hot surfaces.

• Shut off The pressure washer immediately if it

begins to vibrate excessively.

• Do not ll the gas tank indoor. Wipe any spilled

gas before attempting to start the pressure washer.

• Stop engine before leaving the area. Never leave

a running unit unattended.

• Always relieve pressure after engine has

stopped!