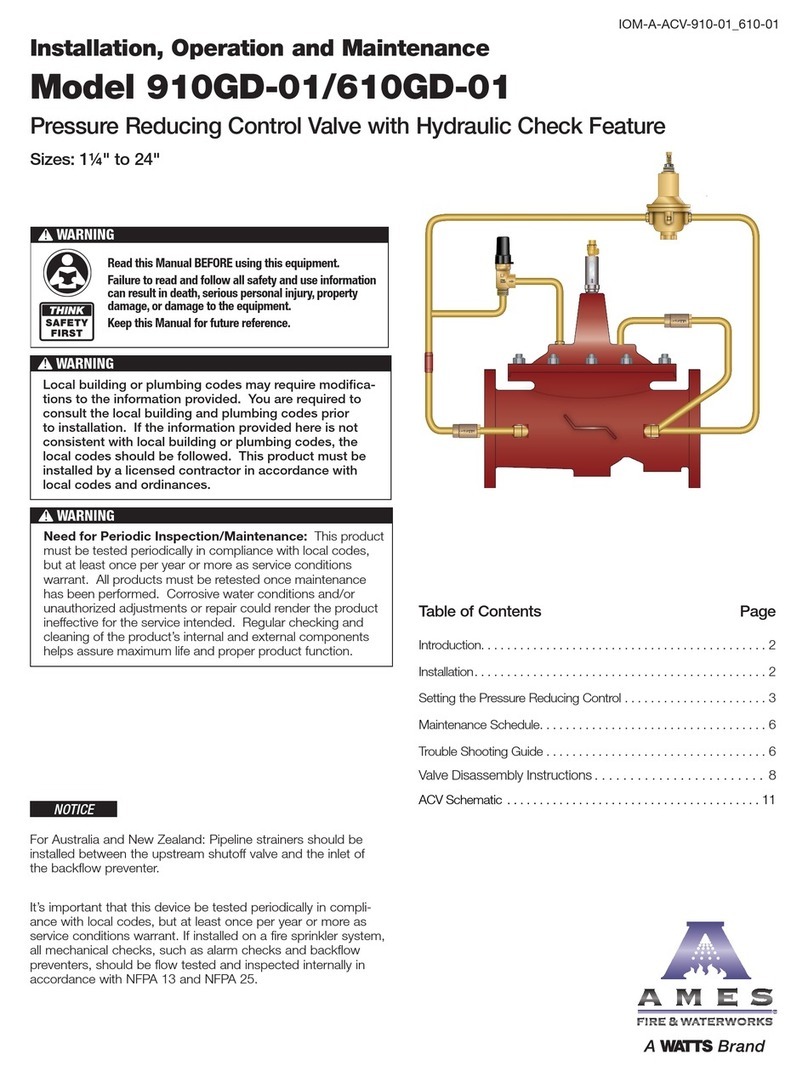

2

NOTE: Ames assemblies require minimum maintenance. All

assemblies must be retested once maintenance has been

performed. Before servicing be certain shut off valves are closed.

A. The installation and maintenance of any Ames Detector

Check Valve should be performed by a qualified licensed

technician. Failure to do so may result in a malfunctioning

assembly. All instructions should be read thoroughly by the

technician before installation or performing any maintenance

on the assembly.

B. Before installing an Ames Detector Check Valve, flush the

lines thoroughly to remove all debris, chips and other foreign

objects. Failure to do so may make the assembly inoperable.

C. Allow sufficient clearance around the installed assembly to

conduct testing, servicing and inspection. Allow a minimum of

12" from the flood level to the bottom of the assembly.

D. Be sure to contact local code authorities for proper

installations.

INSTALLATION NOTE: The flange gasket bolts for the gate valves

should be retightened during installation as the bolts may have

loosened due to storage and shipping.

ATTENTION INSTALLER: After installation, please leave this

Instruction Sheet for occupant’s information.

Installation Instructions

Removing Cam-Check

Place yourself so that the water flow through the valve is left to right.

1. Shut down water system by closing two gate valves and lock out

system if possible. Slowly open bleed port to relieve internal pressure.

After pressure is relieved, loosen bolts on groove coupler and remove

groove coupler and copper plate from valve body.

2. Unscrew (counter clockwise as viewed through the port facing the

check) the Cam-Check. Insert the two grooved coupler bolts into the

holes in the face of the seat. Be sure that the pins or bolts are

installed with one on each side of the cam bar as shown. Insert a long

screwdriver or pry bar between opposing pins and loosen the check

counter clockwise) until it comes free to turn by hand. Finish unscrew-

ing the Cam-Check by hand using the support ears for the clapper

and cam bar to turn the check. (See fig #1A)

3. Lift the Check straight up and out of the port access hole.

4" and 6" Cam-Check Removal

4" and 6" Cam-Check Installation

Install the Cam-Check

Prior to installing the Cam-Check, ensure that all threads are clean

and free of debris, grit, or other particles. Thoroughly clean O-rings

grooves and lubricate O-rings with an FDA approved lubricant.

1. Insert the Cam-Check through the cover port with the clap-

per facing down. Align the threads of the Cam-Check with

the threads in the body and start to thread the Check in by

hand - using the ears which extend from the seat ring to

turn the check assembly. DO NOT use the clapper or the

cam bar to turn the check assembly.

2. Tighten the Cam-Check. Insert grooved coupler bolts into

the holes in the face of the seat (or use the bolts from the lid

groove coupler). Be sure that the pins or bolts are installed

with one on each side of the cam bar. Insert a long screw

driver or pry bar between opposing pins and tighten the

check (clockwise as viewed through the port facing the

check) until it comes to a solid stop. The back the check

out about 15 degrees or from the 1:00 position to the 12:00

position. (See Fig #1B).

START UP: After re-installation of the cover plate and groove coupler — the downstream shutoff valve should be closed. Open upstream

gate slowly, fill the valve and bleed the air through bleed port. When valve is filled, open the downstream shut off slowly. Failure to bleed air

from assembly may cause water hammer or shock damage to the water system.

Figure #1A

Figure #1B