Service, Replacement Parts and Maintenance

CALIFORNIA PROPOSITION 65 WARNING

This product contains lead, a chemical known to the State of California to cause birth defects or other reproductive harm.

(Plumber: California law requires that this warning be given to the consumer.)

CONSUMER INFORMATION ABOUT CALIFORNIA PROPOSITION 65 WARNING

All faucets and products made of leaded brass alloys, even those that comply with U.S. Environmental Protection Agency

regulations, contribute small amounts of lead to water that is allowed to stand in contact with the brass. This product

complies with all E.P.A. regulations regarding the amount of lead used in plumbing brass and solder. The amount of lead

contributed by any faucet/product is highest when the faucet/product is new.

The following steps will reduce potential exposure to lead from faucets and other parts of the plumbing system:

•Always run the water for a few seconds prior to use for drinking or cooking.

•Use only cold water for drinking or cooking.

•If you wish to flush the entire plumbing system of water that has been standing

in the pipes or other fittings, run the cold water until the temperature of the

water drops, indicating water coming from the outside main.

•If you are concerned about lead in your water, have your water tested by an

EPA-certified laboratory in your area.

Ames Model A200 Sizes 3/4” to 2”

Limited Warranty (Full description of limited warranty is found in Ames

Product catalogue.)

This Ames warranty is expressly in lieu of any other warranties, expressed or

implied including without limitation, warranties of MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. Ames shall not be responsible for

any incidental or consequential damages including without limitation, damages

or other costs resulting from labor charges, delays, vandalism, negligence, foul-

ing caused by foreign material, damage from adverse water conditions, chemi-

cals, or any other circumstances over which Ames has no control.

No statement, representation, agreement or understanding, oral or written,

made by agent, by an authorized Ames dealer, an Ames representative or em-

ployee which is not contained in this limited warranty will be recognized or en-

forceable or binding upon Ames Company, Inc. Only a written statement signed

by and officer of Ames may modify this limited warranty.

Any action for breach of any Ames Warranty must be commenced within one

(1) year after date on which cause of action occurred.

Note: Ames assemblies require minimum maintenance. All assemblies

must be retested once maintenance has been performed prior to use.

Internal parts can be removed, repaired or inspected

without removing the valve from the piping.

Freeze Protection Guidelines:

Purging of a PVB Assembly with Pressurized Air:

1. Close main shut-off valve.

2. Open upstream drain, test cocks and isolation ball valves to

depressurize line.

3. Purge with pressurized line

4. Leave test cocks and isolation ball valve handles in 45º

angle to drain ball valves and prevent casting damage

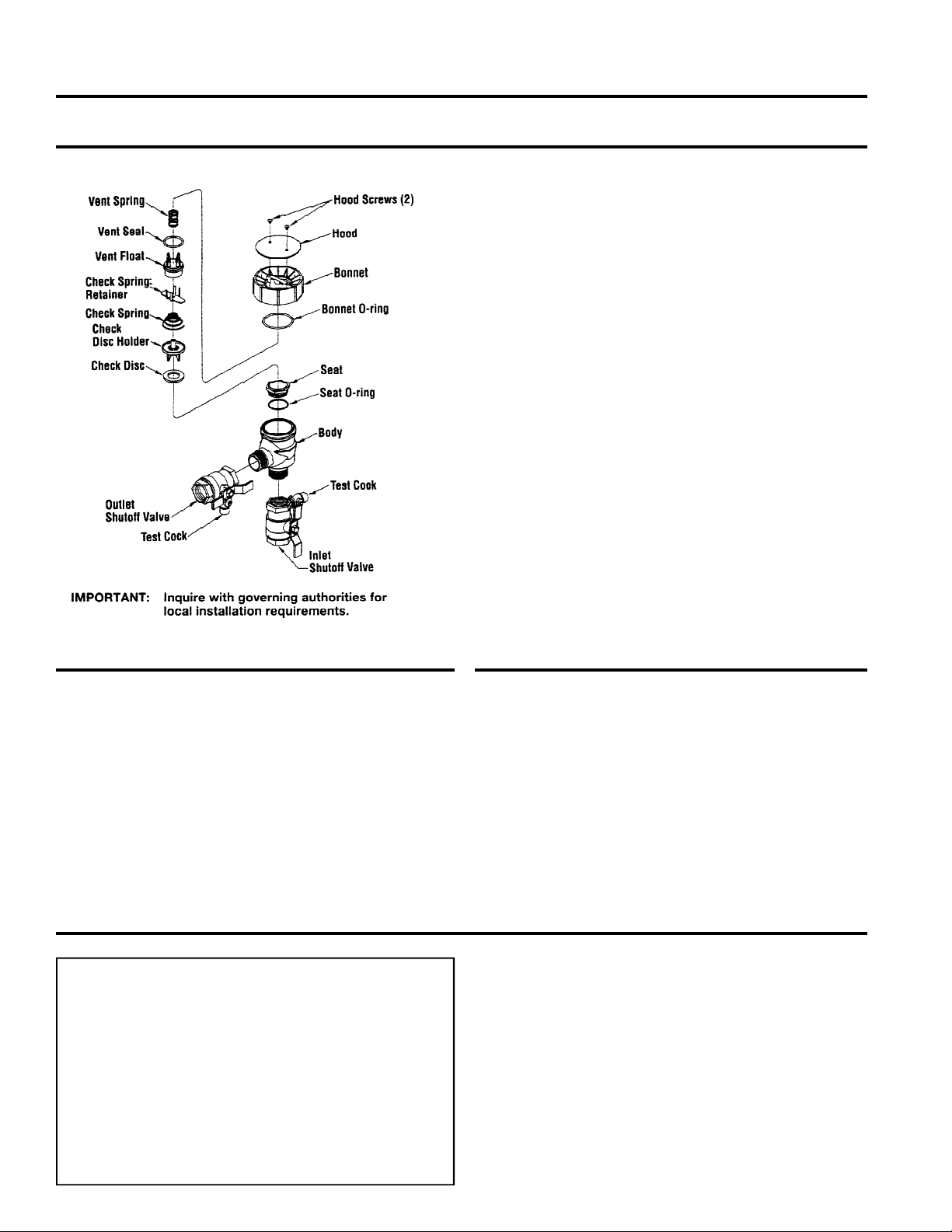

A200 REPAIR KITS

Check Kit: Include Check disc assembly (disc and disc

holder), Bonnet, O-ring and Spring.

Vent Float Kits: Includes Float vent disc assembly, (vent

float, spring) and Bonnet O-ring.

Bonnet Assembly Kits: Include Bonnet, Bonnet O-ring

an Vent Spring.

Rubber Parts Kits: Include Vent disc, Check disc and

Bonnet O-ring.

Seal Kits: Include Seat, Seat O-ring and Bonnet O-ring.

Disassembly:

1. Shut off the supply pressure and drain the valve.

2. Remove the two hood screws and the hood.

3. Place a wrench on the parallel flats of bonnet and stem

assembly. Turn counter clockwise and remove.

4. Remove the vent assembly.

5. Press down on the spring retainer and disengage it from the

retaining lugs. Then turn 90º and remove.

6. Remove the spring retainer and spring. Note that the large

diameter of the spring is down on the guide assembly.

7. Remove the check disc holder and guide assembly.

8. Disassemble the check disc holder assembly.

Reassembly:

Reassemble in the reverse order utilizing the new parts from

the repair kit.