Advanced Micro Instruments has developed and patented key technologies that enable our devices to

deliver the highest levels of PERFORMANCE, RELIABILITY and EASE-OF-USE. These technologies

are included in THE BARRACUDA MODEL 4010LX and cannot be replicated by any other company.

This powerful software platform comes standard with every MODEL 4010LX

purchase and provides users with access to a full suite of advanced features, including:

– Settings & logic adjustments for 2-fully independent Alarm Relay Contacts

– Security settings to prevent unauthorized adjustments to the Analyzer via the

front panel

– Changing the analog outputs from 4 –20 mA to 1–5 VDC or vice versa

– Datalogger that records measurement readings, temperature of the Cell Block,

gas pressure, brown-outs and power voltage over a period of 15 days @1-min

intervals (data can be displayed on a graph or in tabular format)

– Error Status Display that alerts users to any error(s) detected by the Analyzer

– Communication with the Analyzer via USB Virtual COMport and Modbus

bi-directional RS485 Communication

KEY INNOVATIONS

ELIMINATOR CELL BLOCK

COMMAND CENTER INTERFACE SOFTWARE

ELECTRONICS PLATFORM

command

center

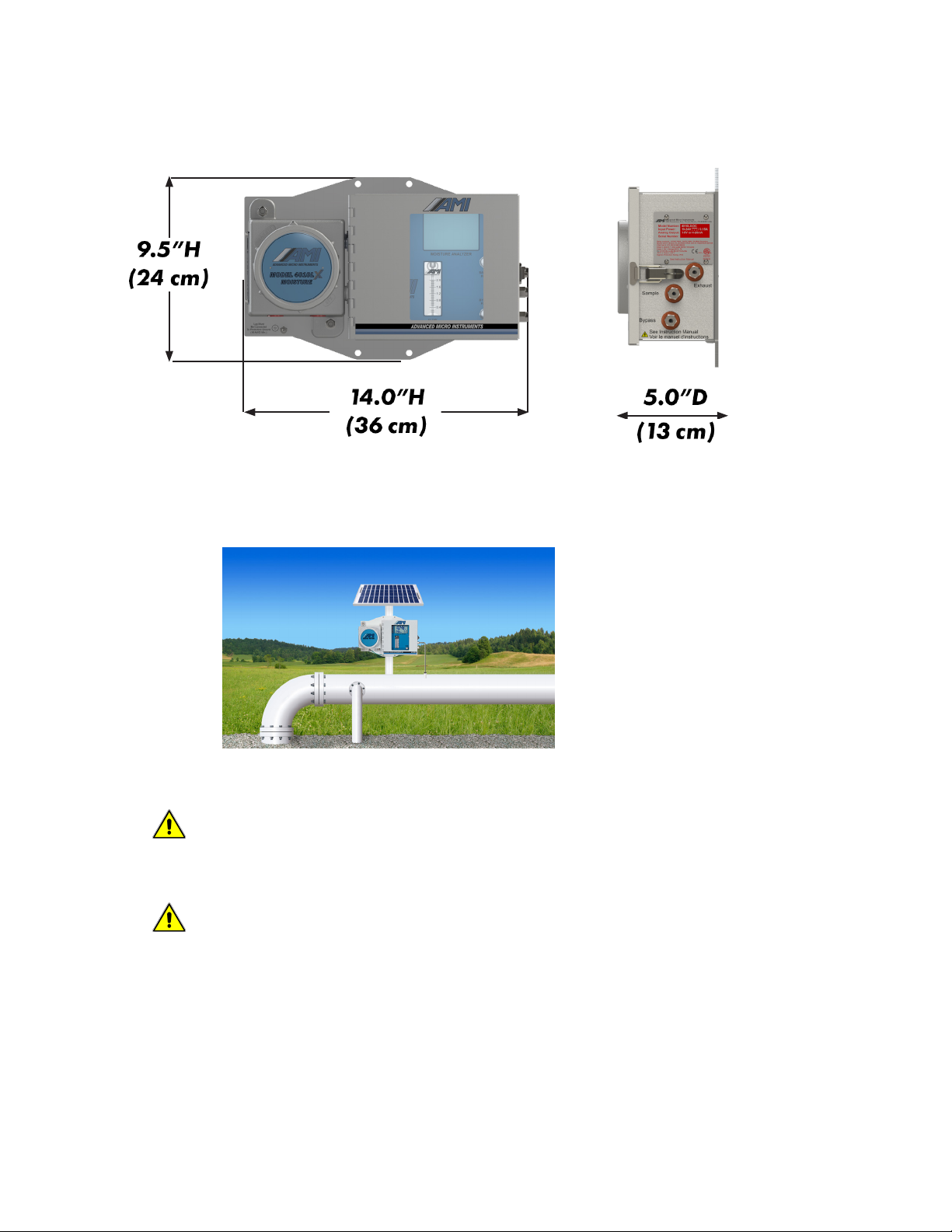

Our patented Cell Block Technology provides the next generation of innovation

for a complete, very compact sample system that virtually eliminates all

potential leak paths while optimizing flow efficiencies. The volume and distance

the sample gas travels prior to entering the laser chamber has been

dramatically reduced.

THE BARRACUDA MODEL 4010LX is programmed with a proprietary

measurement algorithm to carry out trace moisture measurements. Not only will

THE BARRACUDA complete multiple scans every second for the signature

H2O peak and CH₄ (methane) peak, its algorithm contains a compensation

function to account for pressure and temperature. This ensures maximum

stability and accuracy regardless of the methane levels.

MEASUREMENT ALGORITHM AND SMART CALIBRATION

A Smart Calibration feature is also enabled on THE BARRACUDA. Over

time, laser-based Moisture Analyzers eventually see a gradual movement of

their signature peaks on the x-axis of the measurement waveform. THE

BARRACUDA MODEL 4010LX can easily realign the laser to the critical H2O

peak and CH4peak through the touch of a button.

All sample handling components, including the Herriott Cell, have been

machined from a series of solid compact blocks with precision-drilled

intersecting passages in place of long lengths of tubing and compression fittings.

Additionally, metering valves, pressure sensor and flowmeter are all directly

integrated into the machined blocks.

Finally, the ELIMINATOR CELL BLOCK features a unique liquid rejection/

particulate membrane that is sealed between cell blocks. As a result, all

liquids and particulate are effectively exhausted through the bypass without

ever reaching the optical components.

5