Amptek Inc. XR-100CR Manual

- 8 -

4 OPERATING NOTES FOR THE XR-100CR CONNECTED TO THE PX2CR

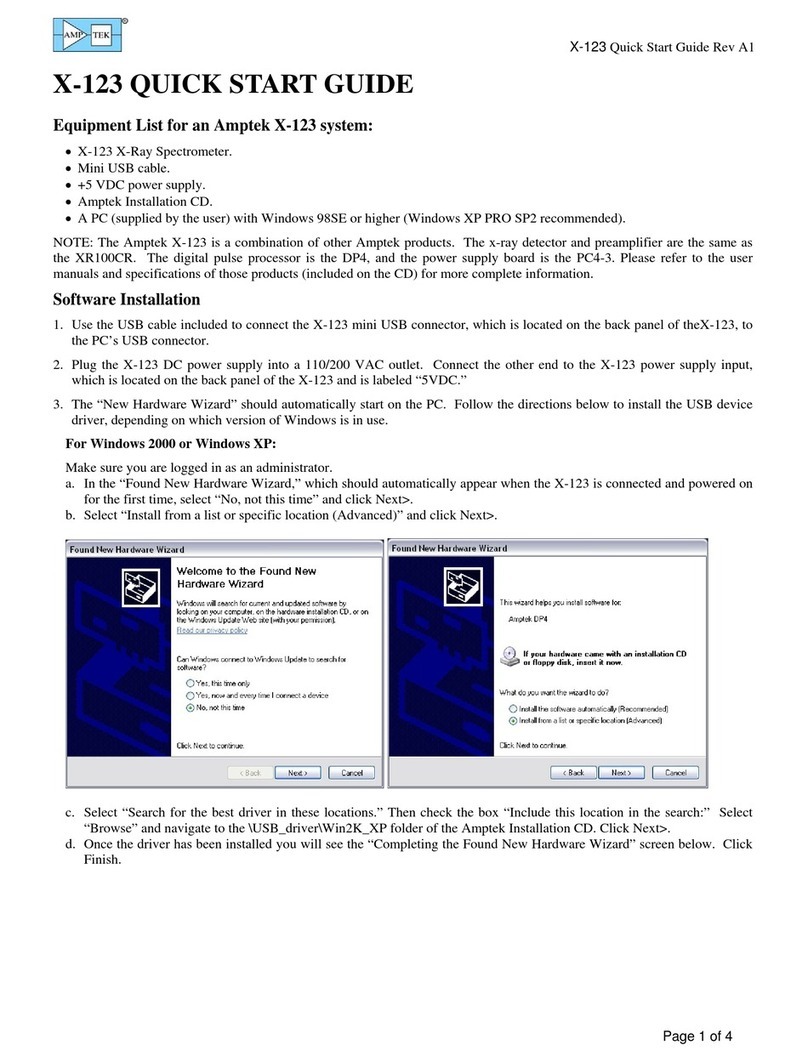

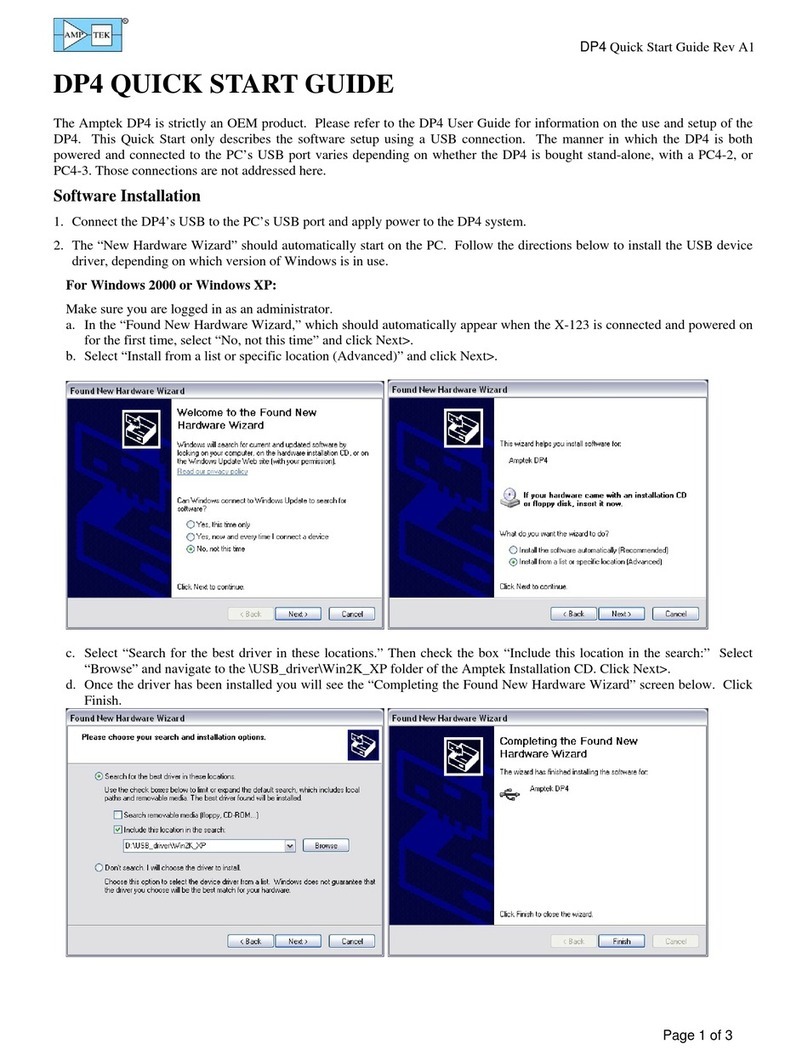

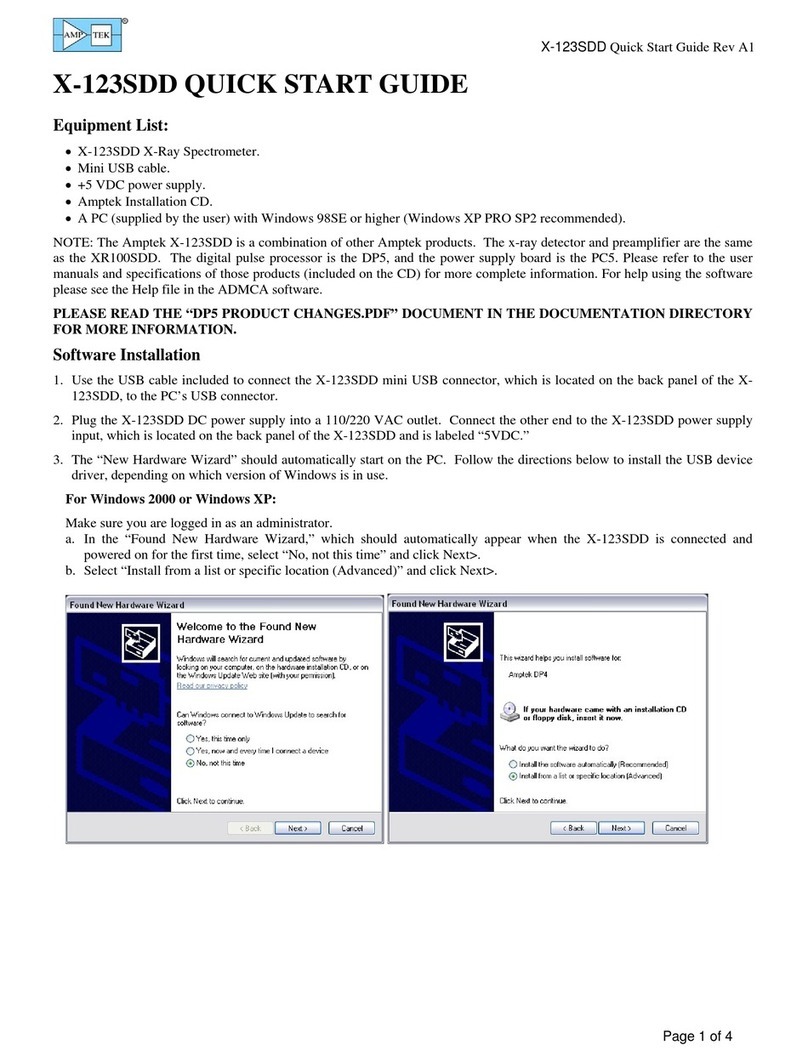

1. Turn the power to the PX2CR OFF.

2. Connect the 9-Pin D-Connector from the XR-100CR to the PX2CR.

3. Connect the Output of the XR-100CR (OUT) directly to the Input of the PX2CR (AMP IN) with

a BNC cable. DO NOT terminate the cable with a 50 termination.

4. Connect the Output of the PX2CR (AMP OUT) directly to the input of a Multichannel Analyzer

(MCA). DO NOT terminate the cable with a 50 termination.

5. Connect the +/- TEMP from the PX2CR to a µA meter.

6. Turn the AC power to the PX2CR ON via the rear panel switch.

7. Observe the µA meter. As the temperature of the cooler decreases, the µA meter will decrease

from 293 µA to about 250 µA. The temperature monitor IC provides 1 µA per 1°K. Please note:

room temperature = 293°K = 20°C.

NOTE:

Depending on the detector type, the internal temperature monitor could be a Diode sensor instead of an

IC sensor. If it is an IC sensor, the above instructions are valid. If it is a Diode sensor, please see

below.

For detectors with Diode temperature sensors:

The +/- TEMP MONITOR on

the PX2CR will be measured in

mV instead of A. The graph to

the right is used to cross

reference the mV reading to the

actual detector temperature in

degrees C.

If the PX2CR was ordered

together with a detector that has

a Diode temperature sensor, it

has been modified at the factory

to directly read in mV across the

(+ TEMP -) banana terminals.

This modified PX2CR is set at

the factory to provide 800 A of

current through the diode and

provide a TEMP reading in mV

only.

If a customer has both types of detectors with IC and Diode temperature sensors, the measurement can

still be made with a standard PX2CR that has not been modified exclusively for the Diode sensor. For

the IC operation, perform the A measurement as described in steps 5, 6, and 7 above. For Diode

operation, connect the two + and - terminals together with a banana shorting plug and measure mV

between the shorted + and - banana plug and the PX2CR chassis ground. Then cross reference the mV

reading to the graph in order to get degrees C.

XR100 Temperature Sensor Calibration

1N914 Lot #P1839244 I = 800uA

y = -0.4329x + 281.5

-65

-55

-45

-35

-25

-15

-5

5

15

25

590 610 630 650 670 690 710 730 750 770 790 810

mV

deg C

7/19/02