Measumax 10-124 User manual

Electronic Micrometer Operation Manual

Models 10-124, 10-1242

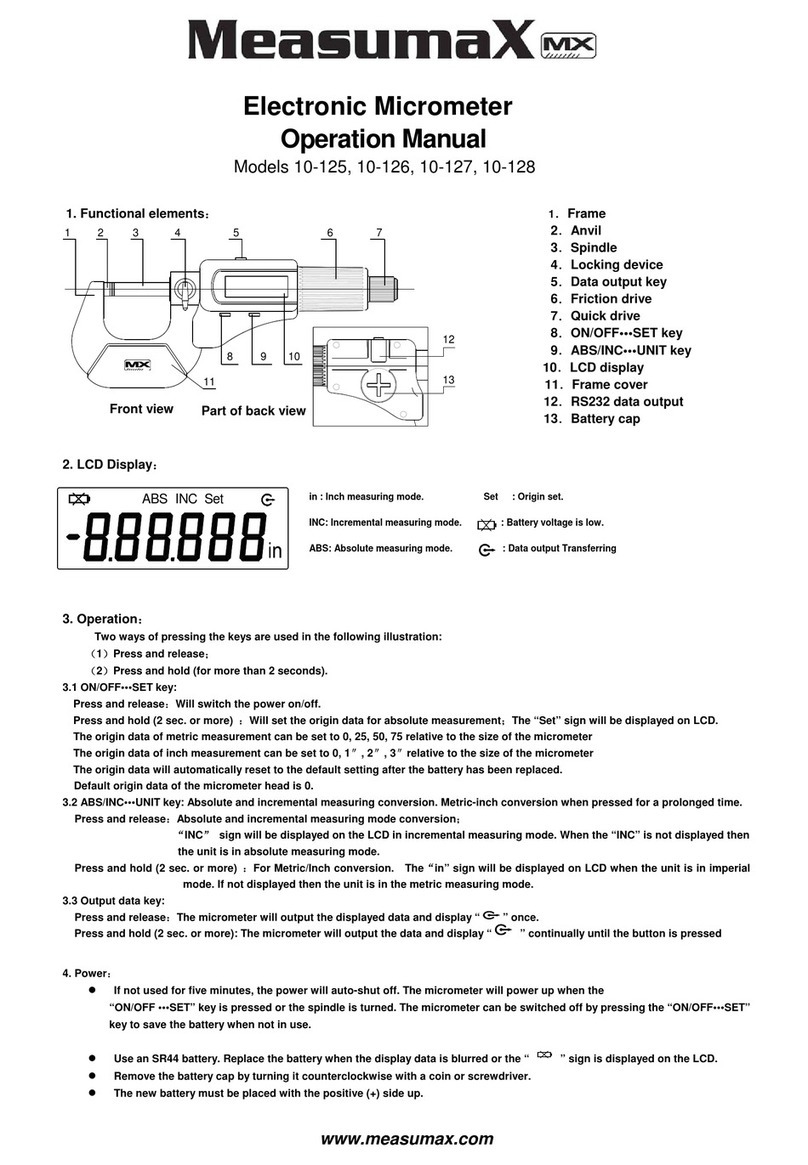

1. Functional elements

2. LCD Display

1. Frame

2. Anvil

3. Spindle

4. Locking device

5. Data output key

6. Friction drive

7. Quick drive

8. ON/OFF•••SET key

9. ABS/INC•••UNIT key

10.LCD display

11.Frame cover

12.RS232 data output

13.Battery cap

Front View Part Back View

www.measumax.com

Electronic Micrometer

Operation Manual

Models 10-124,10-1242

1. Functional elements::

2. LCD Display::

3. Operation::

Two ways of pressing the keys are used in the following illustration:

((1))Press and release;;

((2))Press and hold (for more than 2 seconds).

3.1 ON/OFF•••SET key:

Press and release::Will switch the power on/off.

Press and hold (2 sec. or more) ::Will set the origin data for absolute measurement;;The “Set” sign will be displayed on LCD.

The origin data of metric measurement can be set to 0, 25, 50, 75 relative to the size of the micrometer

The origin data of inch measurement can be set to 0, 1″″, 2″″, 3″″relative to the size of the micrometer

The origin data will automatically reset to the default setting after the battery has been replaced.

Default origin data of the micrometer head is 0.

3.2 ABS/INC•••UNIT key: Absolute and incremental measuring conversion. Metric-inch conversion when pressed for a prolonged time.

Press and release::Absolute and incremental measuring mode conversion;;

““INC””sign will be displayed on the LCD in incremental measuring mode. When the “INC” is not displayed then

the unit is in absolute measuring mode.

Press and hold (2 sec. or more) ::For Metric/Inch conversion. The““in” sign will be displayed on LCD when the unit is in imperial mode.

If not displayed, then the unit is in the metric measuring mode.

3.3 Output data key:

Press and release::The micrometer will output the displayed data and display “ ” once.

Press and hold (2 sec. or more):The micrometer will output the data and display “ ” continually until the button is pressed

4. Power::

If not used for five minutes, the power will auto shut off. The micrometer will power up when the

“ON/OFF •••SET” key is pressed, or the spindle is turned. The micrometer can be switched off by pressing the “ON/OFF•••SET”

key to save the battery when not in use.

Use an CR2032 battery. Replace the battery when the display data is blurred or the “ ” sign is displayed on the LCD.

Remove the battery cap by turning it counterclockwise with a coin or screwdriver.

The new battery must be placed with the positive (+) side up.

Front view

12 3 4 5 67

11

89 10

12

Part of back view

1

..Frame

2

..

Anvil

3

..

Spindle

4

..

Locking device

5

..

Data output key

6

..

Friction drive

7

..

Quick drive

8

..

ON/OFF•••SET key

9

..

ABS/INC•••UNIT key

10

..

LCD display

11

..

Frame cover

12

..

RS232 data output

13

..

Battery cap

13

in : Inch measuring mode.

INC: Incremental measuring mode.

ABS: Absolute measuring mode.

Set : Origin set.

:: Battery voltage is low.

: Data output Transferring

ABS Set

INC

3. Operation

Two ways of pressing the keys are used in the following illustration:

(1)Press and release.

(2)Press and hold (for more than 2 seconds).

3.1 ON/OFF•••SET key:

• Press and release: Will switch the power on/o.

• Press and hold (2 sec. or more): Will set the origin data for absolute

measurement, The “Set” sign will be displayed on LCD.

• The origin data of metric measurement can be set to 0, 25, 50, 75 relative to

the size of the micrometer

• The origin data of inch measurement can be set to 0, 1″, 2″, 3″relative to the

size of the micrometer

• The origin data will automatically reset to the default setting after the battery

has been replaced.

• Default origin data of the micrometer head is 0.

3.2 ABS/INC•••UNIT key:

Absolute and incremental measuring conversion. Metric-inch conversion

when pressed for a prolonged time.

• Press and release: Absolute and incremental measuring mode conversion:

“INC” sign will be displayed on the LCD in incremental measuring mode.

When the “INC” is not displayed then the unit is in absolute measuring mode.

• Press and hold (2 sec. or more). For Metric/Inch conversion. The“in” sign

will be displayed on LCD when the unit is in imperial mode. If not displayed,

then the unit is in the metric measuring mode.

3.3 Output data key:

• Press and release: The micrometer will output the displayed data

and display “ ” once.

• Press and hold (2 sec. or more): The micrometer will output the data and

display “ ” continually until the button is pressed

4. Power

• If not used for ve minutes, the power will auto shut o. The micrometer will

power up when the “ON/OFF •••SET” key is pressed, or the spindle is turned.

The micrometer can be switched o by pressing the “ON/OFF•••SET” key to

save the battery when not in use.

• Use an CR2032 battery. Replace the battery when the display data is

blurred or the “ ” sign is displayed on the LCD.

• Remove the battery cap by turning it counterclockwise with a coin or screw-

driver.

•The new battery must be placed with the positive (+) side up.

5. Data output

• Data output interface is RS232C.

•The micrometer can be connected to a PC’s serial port, or USB port, serial

port by using the correctly congured cables

•Remove the cap of the output connector and insert the cable. (Do not re-

move the cap of the cable plug as it is water resistant.

5.1 Serial port format

Baud rate 1200KB/S Stop bit 2

Start bit 1 Parity none

Data bit 7 Data logic reverse

5.2 Data output format

order12345678910

Metric S N1 N1 N ° N N N CR LX

Inch S N1 ° N N N N N CR LX

S=Minus or Space N1=Minus or Space or digit 0-9 N=Digit 0-9

6. Precautions

• Do not subject the instrument to blows or knocks.

• Do not drop it or apply excessive force.

• Do not disassemble the instrument.

• Do not press the keys with a pointed object. Only press the keys in the

direction intended to insure correct sensitivity.

• Do not use or store the instrument under direct sunlight, or in extreme

temperatures.

• Do not let the instrument near strong magnetic elds and high voltage.

• Use a soft dry cloth to wipe stains from the instrument. Do not use organic

solvents such as acetone and benzene. Wipe measuring faces of the instru-

ment before use it.

• Remove the battery if the instrument is not to be used for a long period of

time.

7. Specications

Measuring force: 5~10N Power consumption: <=35μA

Operating temperature: 0 ~ 40°C Storage temperature: -20 ~ 60

• Button & coin batteries (new or used) are hazardous and are to be kept away

from children

•If a lithium button/coin battery is swallowed or placed inside the body can cause

fatal injuries in 2 hours or less

•If a non-lithium button /coin battery is swallowed or placed inside the body can

cause serious injuries

•Medical attention should be sought immediately if suspected the battery has

been swallowed or placed inside the body

•Phone 13 11 26 Australian Poisons Information Centre for 24/7 fast,

expert advice

WARNING!

Electronic Micrometer Operation Manual

Models 10-124, 10-1242

8. Trouble shooting

Failure Causes Repairing

Display “E 1” on LCD. Data overow. Move spindle in reverse or

press the “ON/OFF•••SET” key.

Display “E 3” on LCD. 1. Sensor overow.

2. Faulty sensor.

1. Reset battery.

2. Return the micrometer for repair.

Measuring data is not correct. 1. Battery not correctly positioned.

2. Flat battery

1. Clean measuring surfaces.

2. Inspect preset data and reset it.

No display on LCD. 1. Battery not correctly positioned.

2. Flat battery

1. Reset battery.

2. Replace battery.

1. Display isn’t steady.

2. Display is illegible.

1. Battery voltage is under 1.45v.

2. Battery voltage is under 1.45v.

1. Replace battery.

2. Replace battery.

1. Display blurred.

2. The output data is wrong.

Battery voltage under 1.45v. Replace battery.

The output data failed The cable not correctly connected Insert the cable again and check for correct

connection.

Display “E 1” on LCD. Data overow. Move spindle in reverse or

press the “ON/OFF•••SET” key.

Display “E 3” on LCD. 1. Sensor overow.

2. Faulty sensor.

1. Reset battery.

2. Return the micrometer for repair.

Measuring data is not correct. 1. Dirty measuring surfaces.

2. Preset data isn’t correct.

1. Clean measuring surfaces.

2. Inspect preset data and reset it.

No display on LCD. 1. Battery not correctly positioned.

2. Flat battery

1. Reset battery.

2. Replace battery.

1. Display isn’t steady.

2. Display is illegible.

1. Battery voltage is under 1.45v.

2. Battery voltage is under 1.45v.

1. Replace battery.

2. Replace battery.

1. Display blurred.

2. The output data is wrong.

Battery voltage under 1.45v. Replace battery.

The output data failed The cable not correctly connected Insert the cable again and check for correct

connection.

SPC DATA DOWNLOAD SYSTEM 40-400

The system is designed to connect the computer and micrometer, to make full use of the electronic micrometers precision and the computer’s data processing

functions. This system expands the electronic micrometers functions and is ideal for use in manufacture, to manage quality controland measurement recording.

For example:

In quality inspection: Pick out the qualied products, reprocess products, and the inferior product

In processing: can record the working situation of machine tools and operators.

Hardware

Connection to the computers from the electronic micrometers through the 9 pin RS232 COM port on the computer, and a small jack plug on the micrometer.

The data is then transferred to the computer every time the “Data” button is presses Measumax can also supply interface units that can connect with 4 or 8

micrometers

www.measumax.com

This manual suits for next models

1

Other Measumax Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

TECNOMOTOR

TECNOMOTOR TM 133 Instructions for use

Shineway Technologies

Shineway Technologies OCC-50 user manual

Testec

Testec TT-HVP 2739 instruction manual

Innerspec

Innerspec ROLLMATE installation instructions

IFM Electronic

IFM Electronic efector300 SD8001 operating instructions

Endress+Hauser

Endress+Hauser Deltapilot M FMB50 Brief operating instructions