1

ONE: INTRODUCTION

Congratulations! You have just purchased one of the most advanced professional Programmable Power Supplies

available. The innovative ergonomic design and overall high quality will provide years of reliable operation.

Therefore, it is very important to completely familiarize yourself with the unit before attempting use. Please read

this manual carefully, paying particular attention to the Warning and Caution sections.

At this time, please fill out the warranty card with all the applicable information and return to American

Reliance. The completed warranty card will ensure the benefits of a three-year warranty. We at American

Reliance, thank you for your selection of one of our products and welcome you to the family of American Reliance

product owners. Remember that, at American Reliance service does not end upon your purchase, it is just

beginning. If you have any questions, please do not hesitate to call our toll-free technical support line at (800) 654-

9838.

1.1 DESCRIPTION

The Programmable Power Supply Series from American Reliance Inc. offers a complete solution to power supply

system requirements. These models are indispensable instruments in assisting in the development and testing of

new products, as well as being standard instruments for automatic test systems. The wide range of output selection

combined with excellent load/line regulation creates a vital instrument in your lab environment.

The PPS Series come standard with a GPIB interface and a three-year warranty. Plus, all units come standard with

output voltage and current programming, overvoltage and overcurrent protection, remote sense, reverse polarity

protection and output enable/disable. All models of the programmable power supply series are able to be calibrated

either in local or remote mode.

1.2 INSPECTION

When you unpack your new programmable power supply from its original packaging, carefully check each item for

damage that may have occurred during shipment. If anything is damaged or missing, please contact American

Reliance at (818) 303-6688 for immediate service.

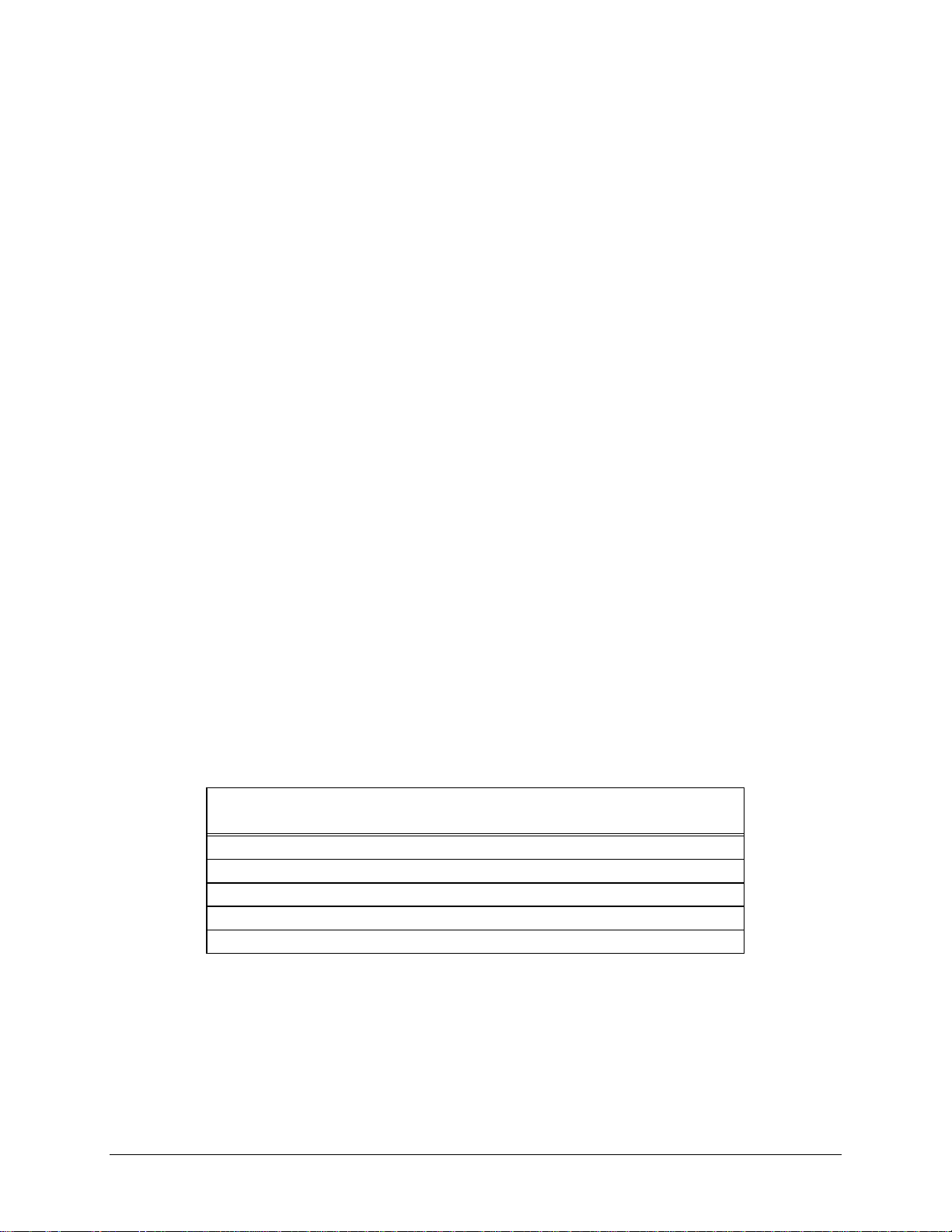

1.3 INCLUDED ITEMS

Programmable Power Supply

Operation Manual

Power Cord

1.4 CAUTIONS AND WARNINGS

1. The input power requirements for the programmable power supplies are 115/230 VAC ±10% or 240VAC

±10%, 50/60 Hz.

2. Before begin to operate the power supply, set the correct voltage 115 or 230(240) VAC setting equal to the

applied voltage, otherwise damage will result to the power supply.

3. Do not use solvents or aromatic hydrocarbons to clean the module as they may damage the finish. If cleaning

is necessary, use only a mild solution of soap and warm water. Be careful not to allow water to enter the unit.

Please be sure to always disconnect the power cord before cleaning.

4. Use only specified fuses. Do not use a substitute fuse which is of a different size and rating. Otherwise, damage

may result to the unit.

5. Do not substitute or modify any internal circuits.