Contents 3

ALF19 Series

Contents

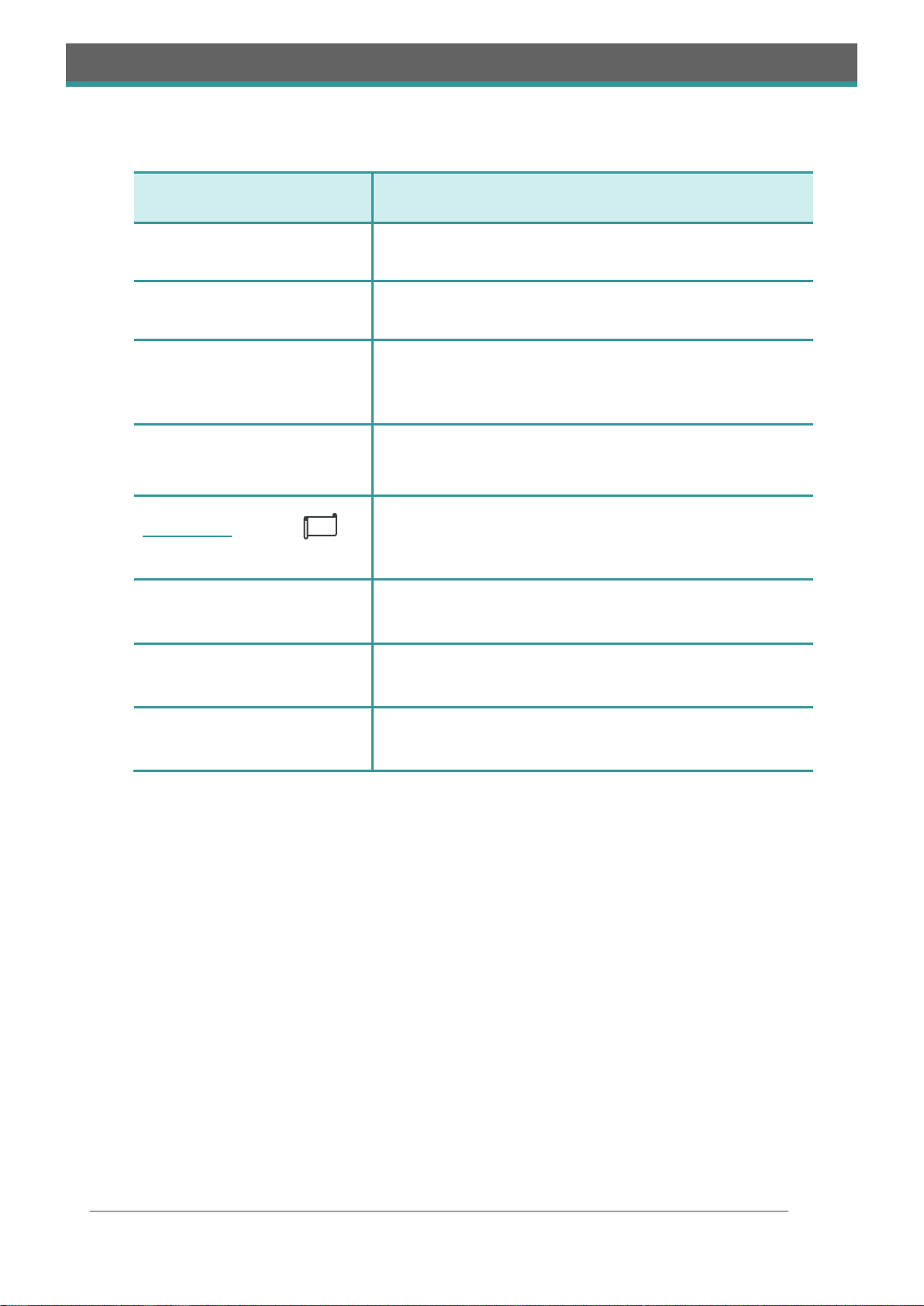

Contents...................................................................................................3

1About these operating instructions.....................................................5

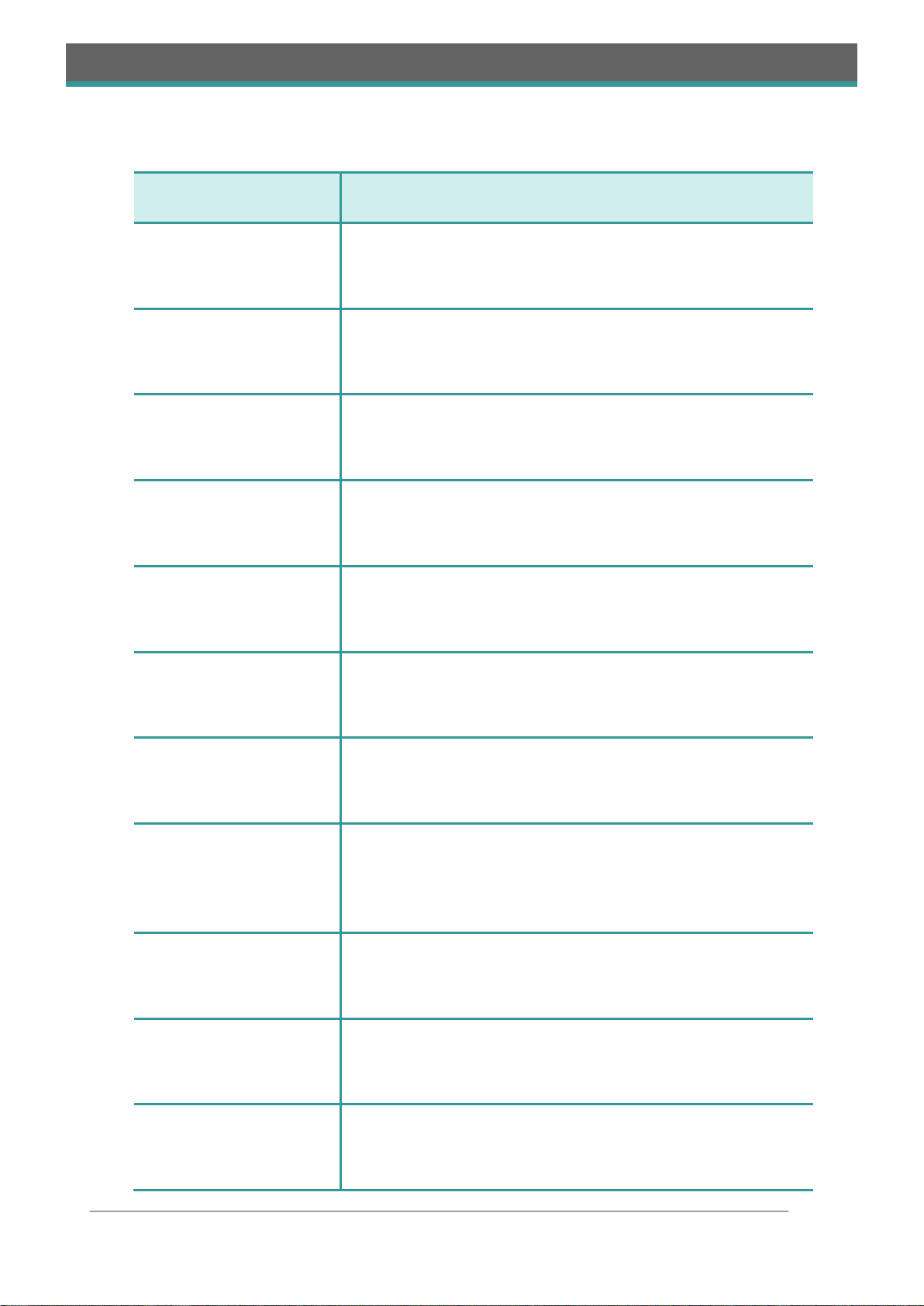

1.1 General information about these operating instructions...........................................5

1.2 Design of the operating instructions......................................................................... 6

1.3 List of abbreviations.................................................................................................. 7

1.4 Glossary.................................................................................................................... 8

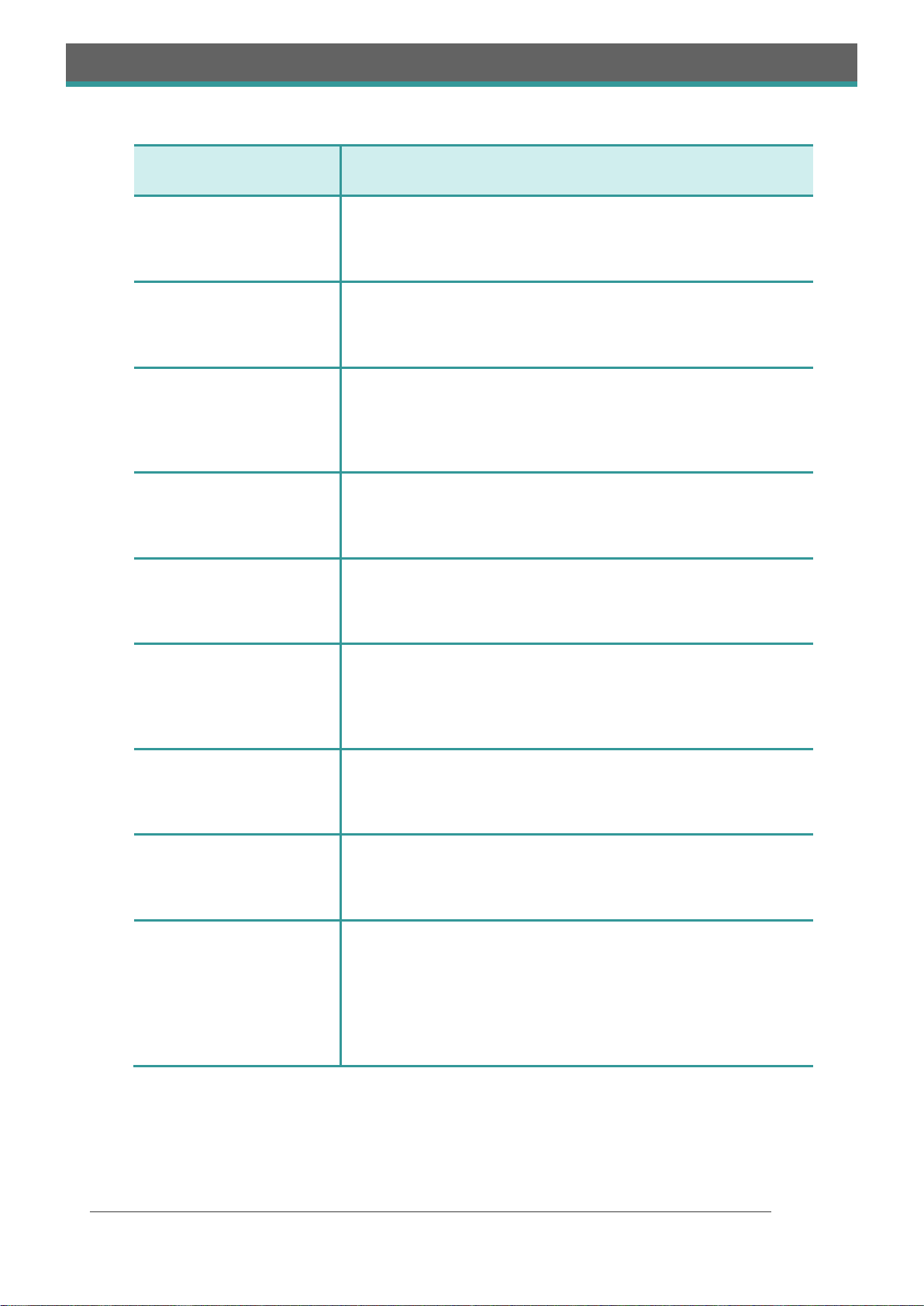

2Safety first ........................................................................................10

2.1 Safe product ...........................................................................................................10

2.2 Intended use........................................................................................................... 10

2.3 Operator responsibility............................................................................................10

2.4 Presentation of warning notices and other information.......................................... 11

2.5 Personnel requirement...........................................................................................13

2.6 General safety information ..................................................................................... 14

3The label feeder at a glance.............................................................15

3.1 Scope of delivery....................................................................................................15

3.2 Short description of the device...............................................................................15

3.3 Views...................................................................................................................... 17

3.3.1 Label Feeder....................................................................................................17

3.3.2 Machine adapter.............................................................................................. 19

3.4 The control panel....................................................................................................21

3.5 Menu structure and settings................................................................................... 23

4Preparing the label feeder for operation...........................................30

4.1 Requirements for the installation site .....................................................................30

4.2 Unpacking the label feeder.....................................................................................31

4.3Power supply..........................................................................................................31

4.4 Mounting the label feeder on the machine adapter................................................ 32

4.5 Threading the label carrier...................................................................................... 35

4.6Setting examples.................................................................................................... 41

5The label feeder in operation............................................................45

5.1 Troubleshooting......................................................................................................47

6Maintaining the label feeder ............................................................. 50

7Packing the label feeder................................................................... 51