AM-TC10626LA

Contents

Precautions...................................................................................................................................................1

1. General Information............................................................................................................................... 3

1.1.

Usage......................................................................................................................................................3

1.2.

Features...................................................................................................................................................3

1.3.

Specifications..........................................................................................................................................3

1.4.

Applicable Range...................................................................................................................................3

1.5.

Working Conditions ...............................................................................................................................3

1.6.

Description of Safety Signs................................................................................................................... 4

1.7.

Position of Safety Signs........................................................................................................................ 4

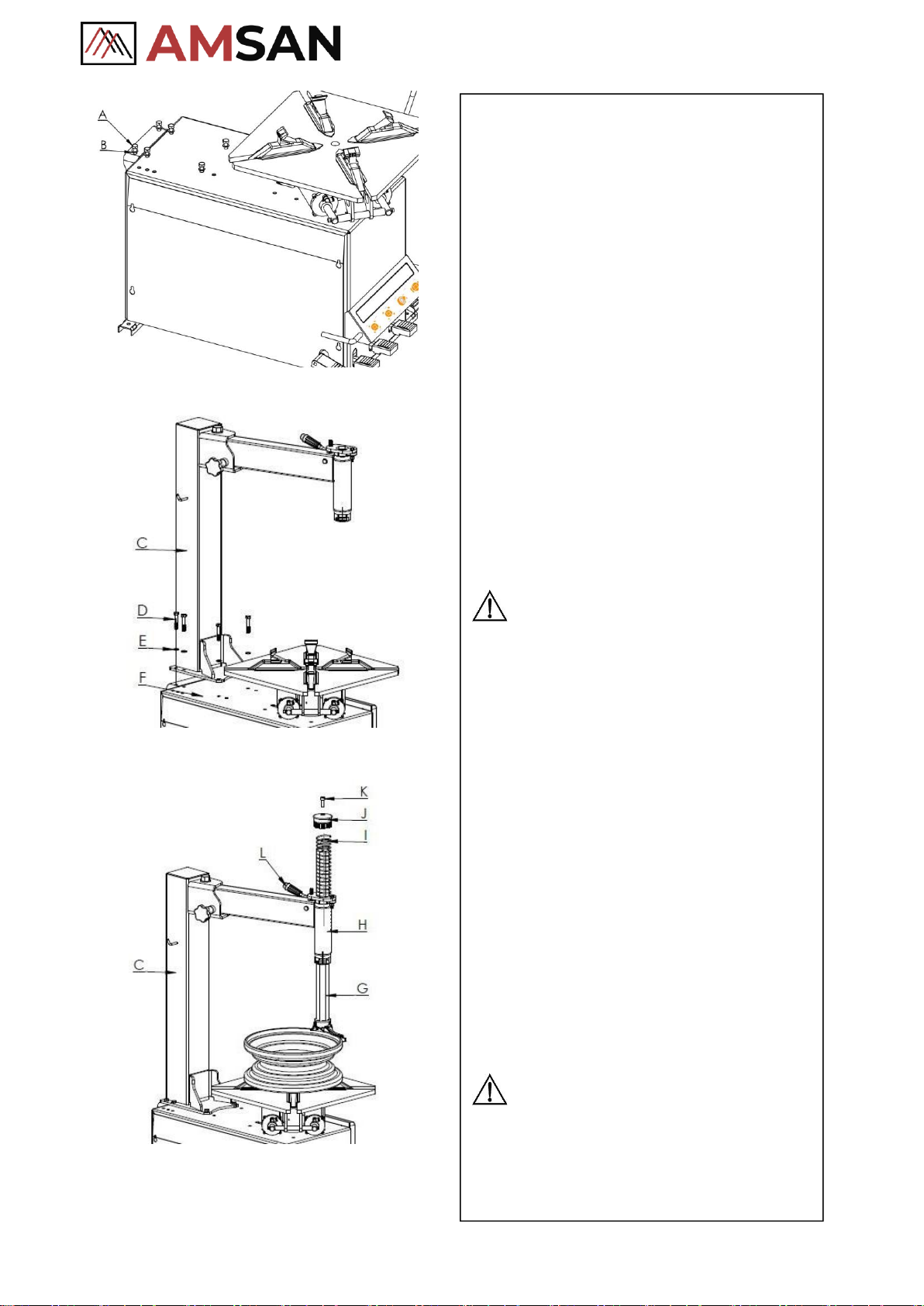

2. Main

Structure

.........................................................................................................................................5

3. Installation and adjusting.......................................................................................................................6

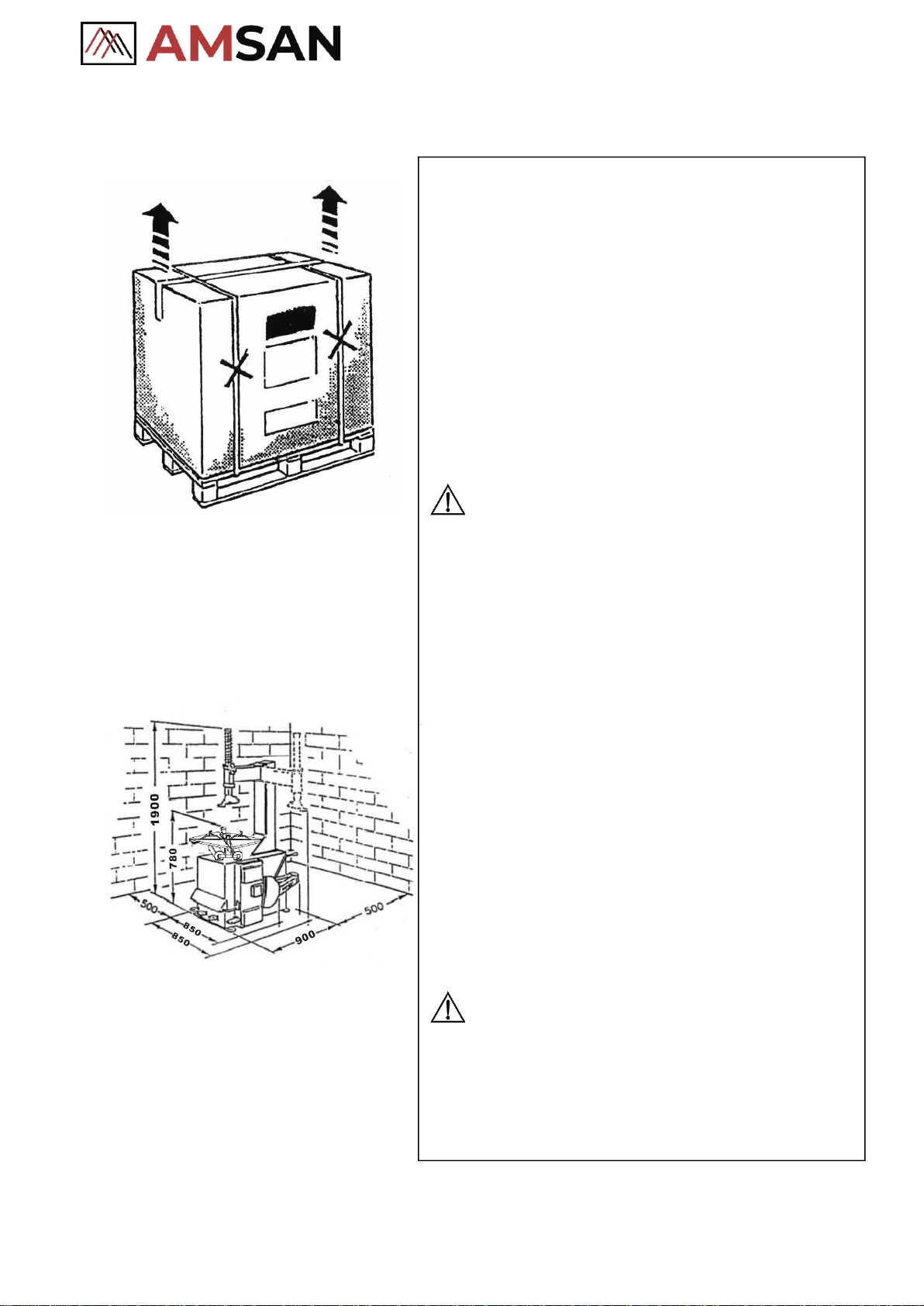

3.1.

Unpacking...............................................................................................................................................6

3.2.

Location..................................................................................................................................................6

3.3.

Installation ..............................................................................................................................................7

3.4.

Power and Air Connections and Regulator.......................................................................................... 10

4. Operation...............................................................................................................................................11

4.1.

Principles..............................................................................................................................................11

4.2.

Demounting

Tire

..................................................................................................................................11

4.3.

Mounting Tire......................................................................................................................................14

4.4.

Inflating Tire......................................................................................................................................... 15

5. Trouble

Shooting

....................................................................................................................................15

6. Maintenance ..........................................................................................................................................

16

7. Storing and Scrapping..........................................................................................................................16

7.1.

Storing ..................................................................................................................................................16

7.2.

Scrapping..............................................................................................................................................16

8. Spare Parts List....................................................................................................................................

17

9. Exploded Drawings............................................................................................................................... 21

9.1.

Column Assembly................................................................................................................................

21

9.2.

Turntable Assembly..............................................................................................................................

22

9.3.

Gearbox & Motor Assembly ...............................................................................................................23

9.4.

Body Assembly ....................................................................................................................................24

9.5.

Bead Breaker Cylinder & Breaker Arm Assembly.............................................................................. 25

9.6.

Quick inflating system (optional)......................................................................................................... 26

9.7.

Simple left help arm (optional)........................................................................................................... 27

9.8. Simple double help arms(optional)....................................................................................................... 34

Appendix1:Electrical

Diagram

..............................................................................................................

40

Appendix 2:Air Passage Diagram .........................................................................................................41

Appendix 3:Optional accessories.........................................................................................................

41

Appendix 4:Maintenance Log ..............................................................................................................

42