Specications Information and Repair Parts Manual 4230-97 and 4231-97

4230-250-00 1 3/2015

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the General Operating

Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property damage! Retain instructions

for future reference. AMT reserves the right to discontinue any model or change specications at any time without incurring any obligation.

©2015 AMT Pump Company, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure to do so

voids warranty.

3/8-Inch Bronze Coolant Pumps

Refer to pump manual 1808-634-00 for General Operating and Safety Instructions.

OPERATION

1. Liquid level should always be at least 2” below the bottom of the motor.

Motor is NOT submersible.

2. Activate the unit. No controls are supplied with this unit. Dry running will

not harm pump or motor.

3. Familiarize yourself and others with all controls for this pump. Learn how

to stop pump/motor quickly in an emergency.

MAINTENANCE

Make certain that the unit is disconnected from the power source before

attempting to service or remove any component! Failure to do so could

result in electrical shock.

LUBRICATION

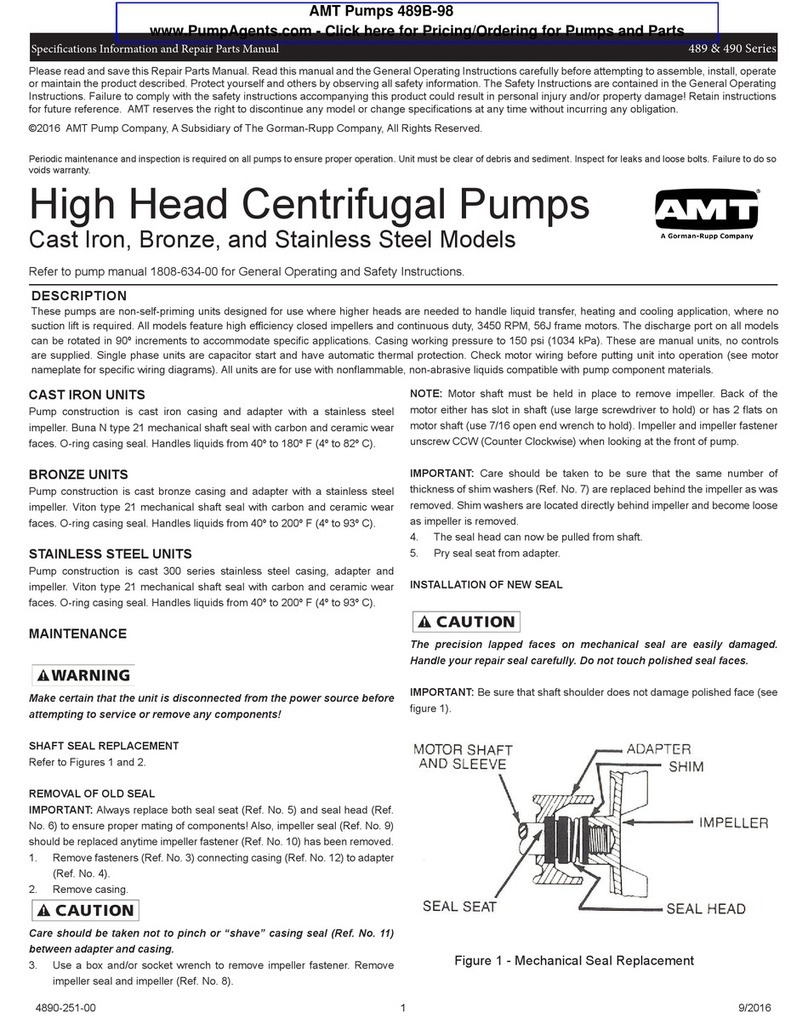

Remove pump from installation and lay on side. Find two oil slots on the side of

the motor (See Figure 2) and put in 4 or 5 drops of SAE 20W oil or its equivalent

every 6 months. Let pump lay on its side for a few minutes to let the oil saturate

the bearing. Do not over-oil. Over-oiling can shorten motor life. Replace rubber

grommets.

IMPELLER MOTOR REPLACEMENT PROCEDURE

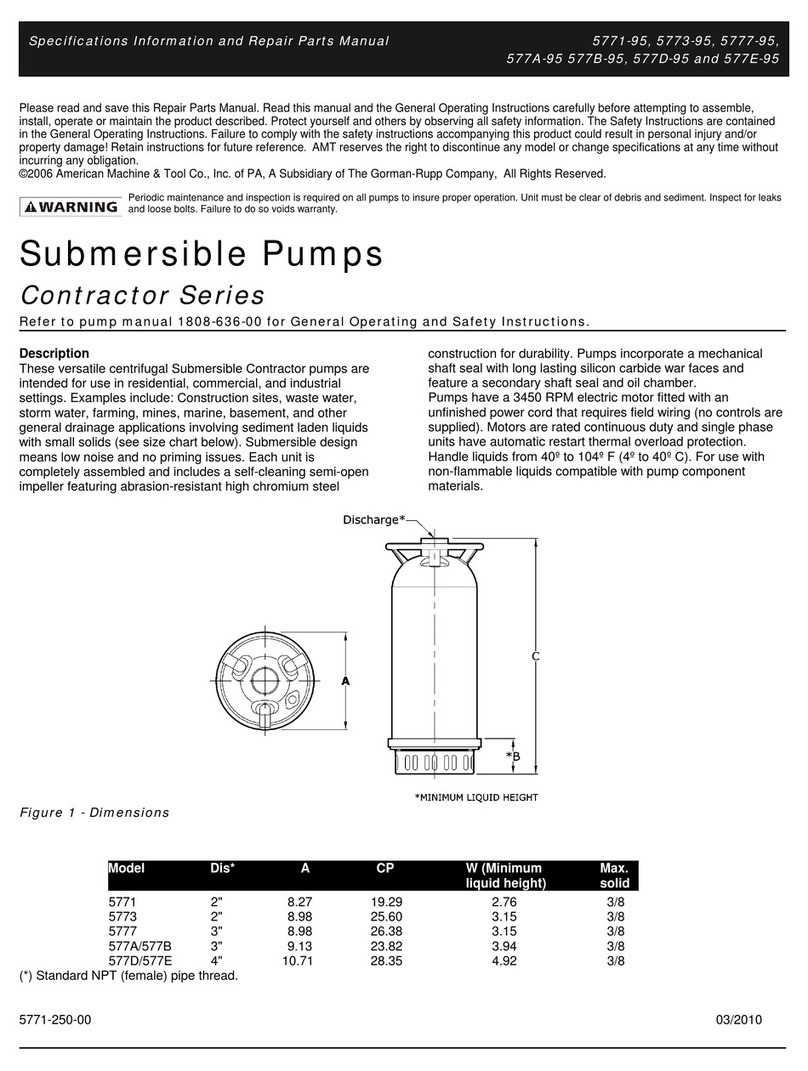

1. Remove base volute housing (Ref. No. 9) by removing three mounting

screws (Ref. No. 5).

2. Remove impeller from impeller tubing (Ref. No. 7). If it doesn’t come off

easily, cut it off.

3. Unscrew motor adapter (Ref. No. 2) from motor exposing impeller tube

without impeller.

4. Cut tubing of impeller assembly diagonally so that it comes off motor

shaft. Do not cut motor shaft.

5. When replacing a new motor, a new impeller assembly must also be

installed.

6. Reassemble pump parts (Ref. Nos. 2, 4, and 6) back onto motor,

tightening screws (Ref. No. 3) into place.

7. Before pressing impeller assembly onto shaft, insert a piece of metal to

hold motor shaft from being pressed out.

8. Turn motor around onto xture and press impeller assembly onto shaft

using tool with guide pin that ts into impeller tube. Press unit in until there

is enough room so it touches neither the volute nor the volute cover while

running.

9. Turn unit on momentarily to see if unit vibrates. If it does, insert a

screwdriver into impeller assembly and bend slightly. Retest to see if

vibration is still there. If it has increased bend opposite way, etc.

10. Replace volute housing. Unit is ready to use.

DESCRIPTION

These coolant/recirculating pumps are heavy-duty units designed for a variety of applications involving evaporative coolers, fountains, laboratories, bilge pumping,

etc. Each pump is equipped with motor, 36” 3-conductor cord, brass tube column and bronze base and impeller. Handles liquids from 40º to 200º F (4º to 93º

C). For use with non-ammable liquids compatible with pump component materials. The motor on this pump is not intended to be submersed in liquid. The liquid

level should be at least 2” below motor bottom.

All 115V motors are equipped with automatic thermal protection. Check motor wiring before putting unit into service (see motor nameplate for specic wiring

diagram). These are manual units, no controls are supplied. All units are for use with nonammable, non-abrasive liquids, compatible with pump component

materials.

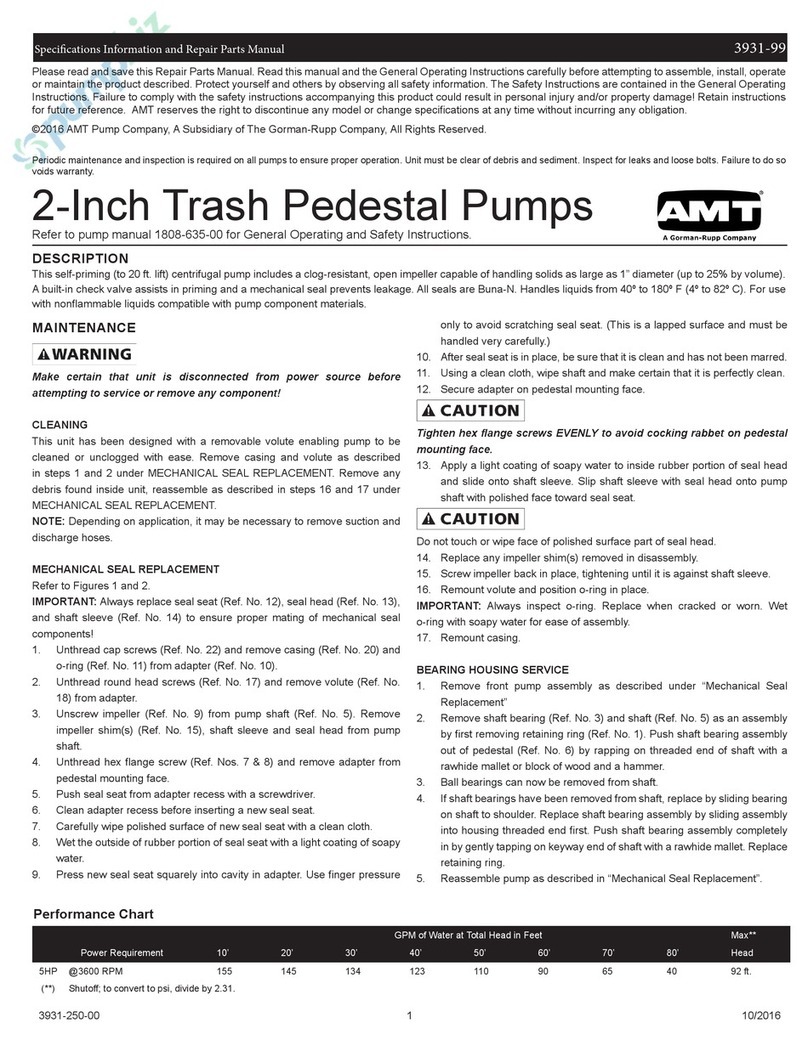

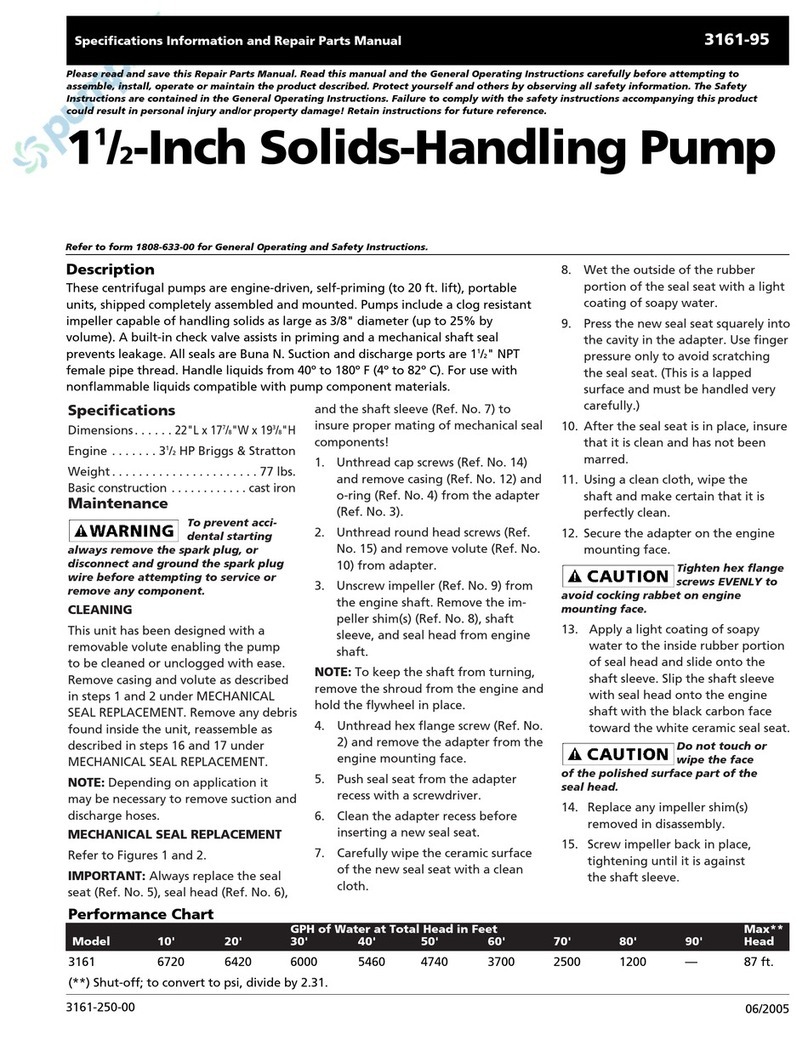

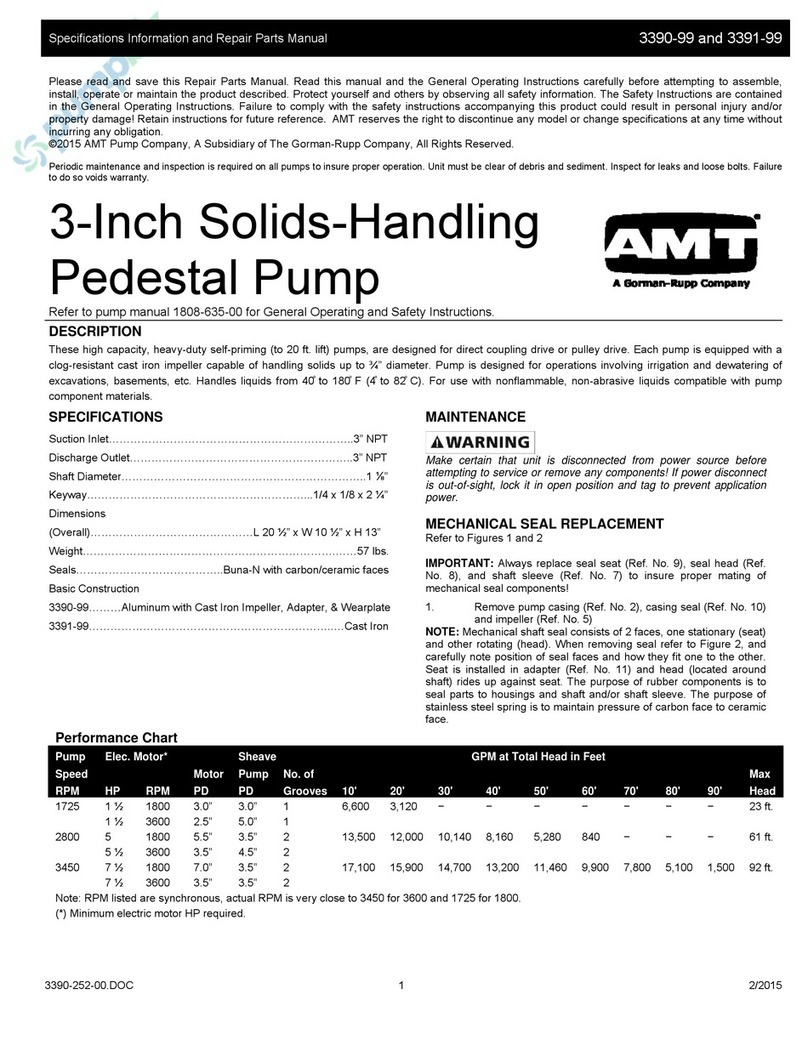

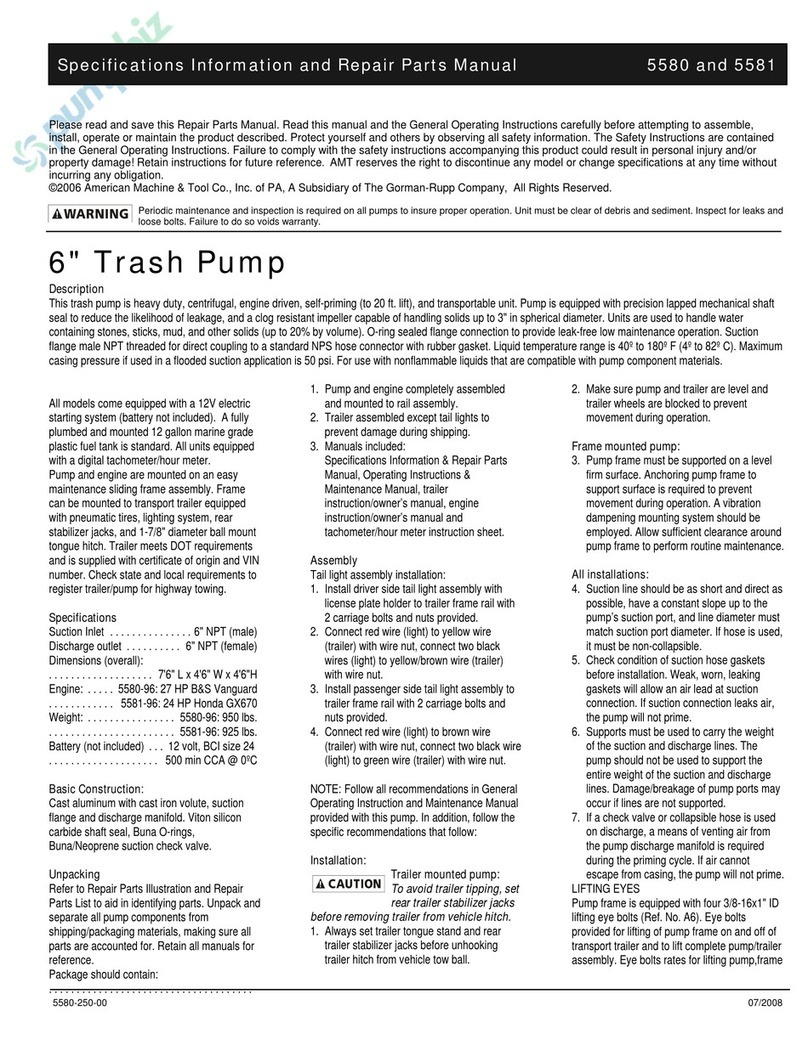

Outlet GPM of Water at Total Head in Feet Shut

Piping 1’ 3’ 5’ 8’ 10’ Off

3/4” ID 8.3 7.1 6.0 3.5 0.8 10.2 ft

1/2” ID 6.7 5.4 4.2 2.0 0.6 10.2 ft

3/8” ID 5.0 3.3 2.2 1.2 0.3 10.2 ft

Performance Chart

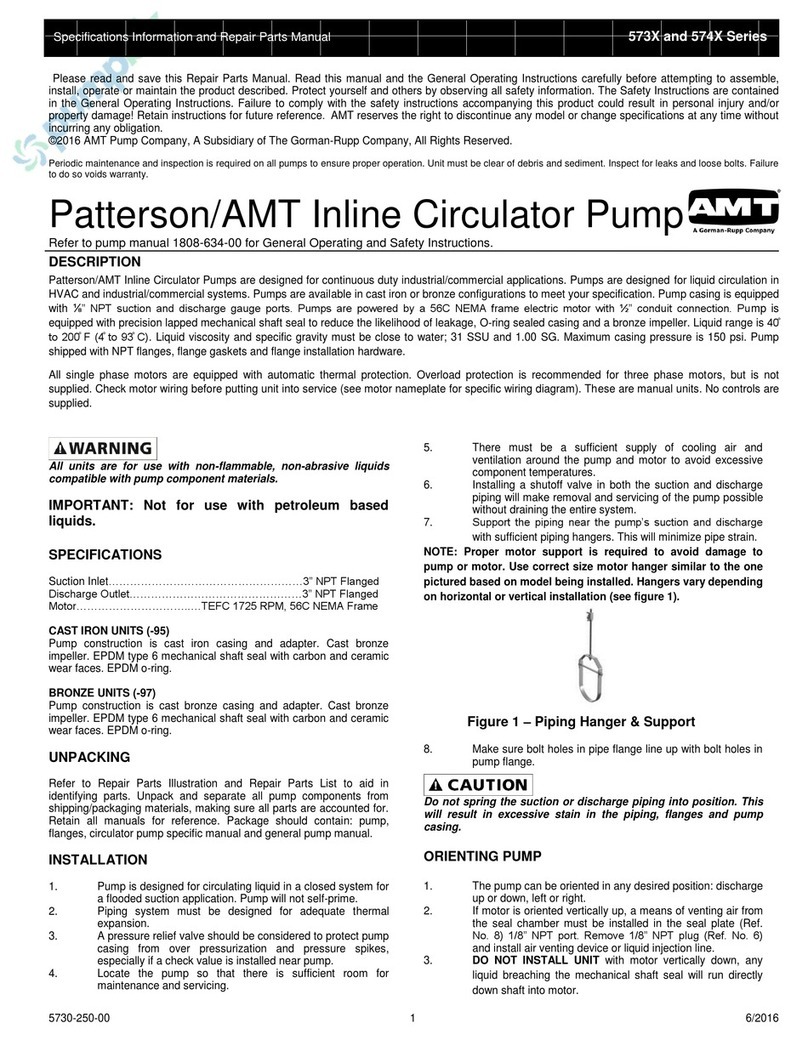

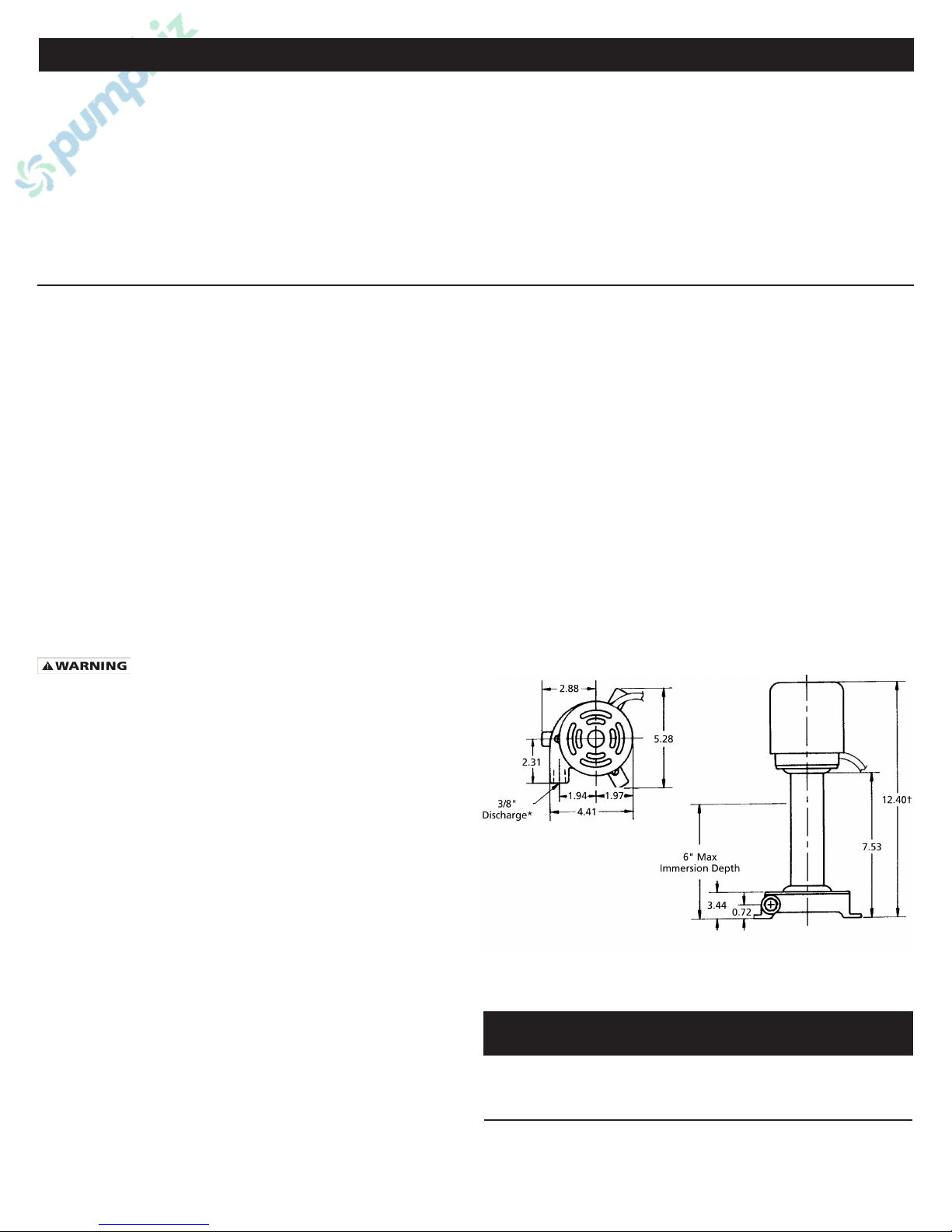

Figure 1 – Dimensions (inches)

NOTE: Dimensions are ±1/8”

(*) Standard NPT (female) pipe thread.

(†) This dimesion may vary due to

motor manufacturer’s specications.