Specifications Information and Repair Parts Manual 3682, 3694, and 3704

3682-251-00

2

Small Straight Centrifugal Pedestal Pumps

MAINTENANCE

Make certain that unit is disconnected from power source before

attempting to service or remove any components!

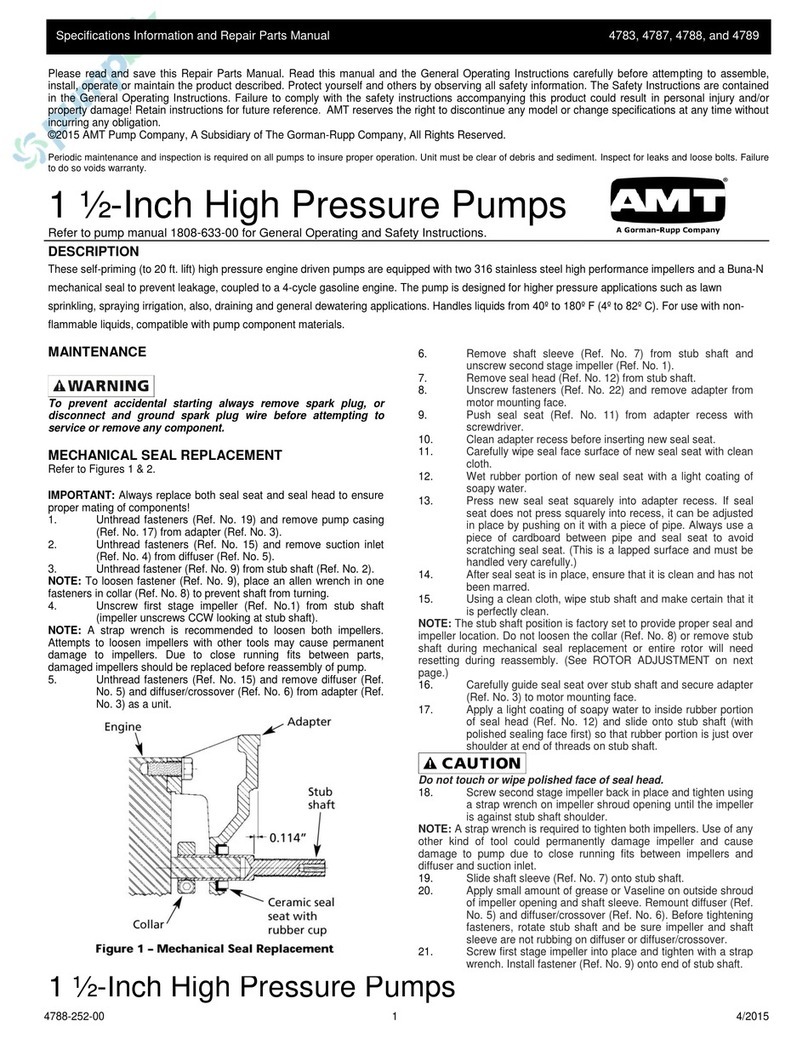

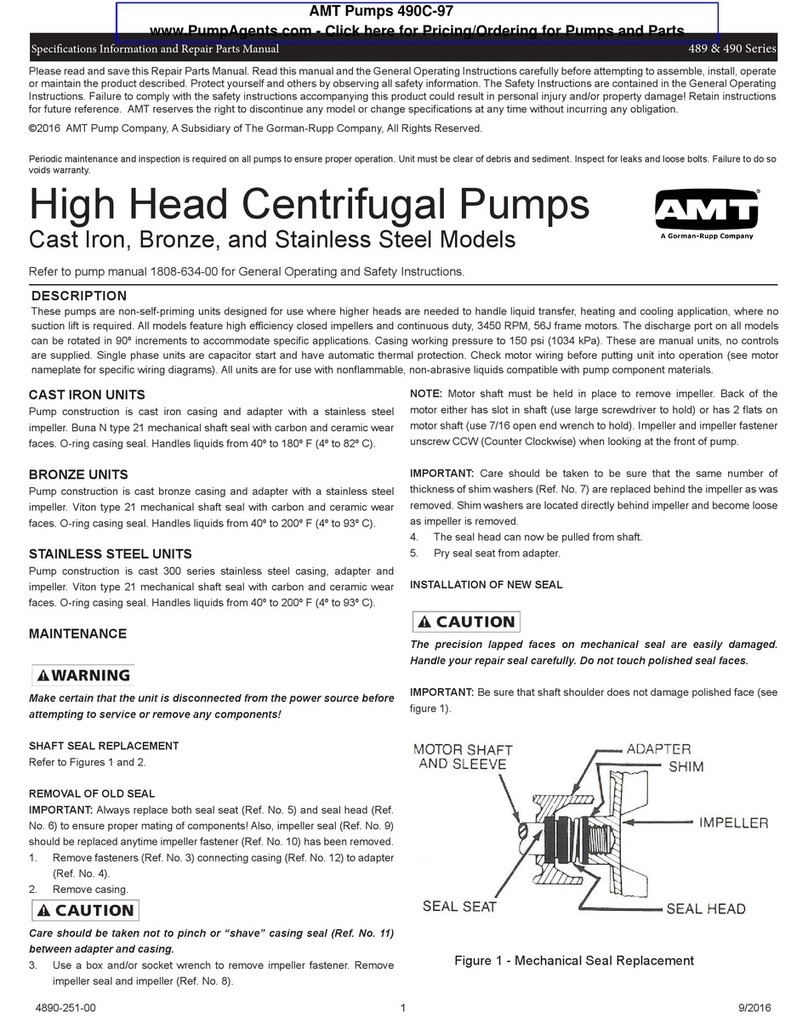

MECHANICAL SEAL REPLACEMENT

Refer to Figure 1.

IMPORTANT: Always replace both seal seat (Ref. No.8) and seal

head (Ref. No. 7) to insure proper mating of components! Also,

impeller seal (Ref. No. 10) should be replaced anytime impeller

fastener (Ref. No. 11) has been removed.

1. Remove fasteners (Ref. No. 14) connecting casing (Ref. No.

13) to pedestal (Ref. No. 5).

2. Remove casing and casing seal (Ref. No. 12).

Care should be taken not to "pinch" or "shave" casing seal

between pedestal and casing.

3. Use a box and/or socket wrench to remove impeller fastener.

Remove impeller seal and impeller (Ref. No. 9). Seal seat

can now be pried from impeller.

IMPORTANT: Care should be taken to ensure that same number and

thickness of shim washers (Ref. No. 8A) are replaced behind impeller

as was removed. Shim washers are located directly behind impeller

and become loose as impeller is removed.

4. To free shaft assembly (Ref. No. 4), see “Bearing Housing

Service”.

5. After shaft assembly is removed, press seal head from

pedestal.

The precision lapped faces on mechanical seal are easily

damaged. Handle your replacement seal carefully. Do not touch

polished seal faces.

IMPORTANT: Be sure that shaft shoulder does not damage polished

seal face.

6. Thoroughly clean all surfaces of seal seat cavity in pedestal

and impeller.

7. While wearing clean gloves or using a clean light rag, press

seal head squarely into pedestal recess, use cardboard

washer (usually supplied with new seal), place over polished

surface and use a piece of pipe or dowel rod to press in

firmly, but gently. Avoid scratching polished face.

8. Dispose of cardboard washer. Check again to see that

polished surface is free of dirt and all other foreign particles

and that it has not been scratched or damaged.

9. Wet rubber portion of new seal seat with a light coating of

soapy water. While wearing clean gloves or using a clean

light rag, press seal seat squarely into impeller recess, use

cardboard washer (usually supplied with new seal), place

over polished surface and use a piece of pipe or dowel rod

to press in firmly, but gently. Avoid scratching polished face.

NOTE: A short "run-in" period may be necessary to provide completely

leak free seal operation.

10. Replace any shim washers which may have been removed

in disassembly.

11. Screw impeller back in place, tightening until it is against

shaft shoulder. Install impeller seal and impeller fastener.

12. Remount casing seal and casing on pedestal.

IMPORTANT: Always inspect casing seal (Ref. No. 12) whenever unit

is disassembled. Replace when cracked or worn.

IMPORTANT: After pump is completely assembled it is necessary to

rotate pump shaft by hand to check for striking of impeller. If striking or

rubbing occurs, adjust impeller shims as required (see “Shim

Adjustment”).

BEARING HOUSING SERVICE

1. Remove casing (Ref. No. 13) and impeller (Ref. No. 9) as

described under “Mechanical Seal Replacement”.

2. Remove shaft assembly (Ref. No. 4) by first removing snap

ring (Ref. No. 1) and shims (Ref. No. 2). Push shaft

assembly out of pedestal by rapping on threaded end of

shaft with a soft mallet, or block of wood and a hammer.

Slinger washer (Ref. No. 6) will come loose at this time.

3. Replace shaft assembly by sliding assembly into pedestal

(be sure to align slinger washer), threaded end first. Push

assembly completely in by gently tapping on keyway end of

shat with a soft mallet. Replace shims and snap ring.

4. Reassemble pump as described under “Mechanical Seal

Replacement”.

SHIM ADJUSTMENT

When installing a replacement impeller (Ref. No. 9) or shaft assembly

(Ref. No. 4), it may be necessary to adjust number of shims (Ref. No.

8A) to ensure proper running clearance between impeller and casing

(Ref. No. 13). Proceed as follows:

NOTE: A proper running clearance is less than 0.010".

1. For impeller replacement, add one 0.010" shim in addition to

those removed originally.

2. For shaft assembly replacement, add two 0.010" shims in

addition to those removed during disassembly.

3. Reassemble pump using “Mechanical Seal Replacement”

for reference.

IMPORTANT: Be sure that casing is snugly in place and check shaft

to make sure it is turning freely. If it turns freely, check to be sure that

pedestal (Ref. No. 5) and casing are fitted "metal to metal" where they

meet on outside. If they are not "metal to metal" tighten fasteners (Ref.

No. 14) and recheck shaft for free turning. Tighten carefully turning

shaft while tightening so that bearings are not damaged in the event

that too many shims were installed. If shaft seizes before fasteners are

completely tight, disassemble pump and remove one 0.010" shim and

repeat reassembly.