1

Contents

1 General description............................................................. 3

1.1 Features.................................................................................... 3

1.2 Main Application and Testing Range......................................... 3

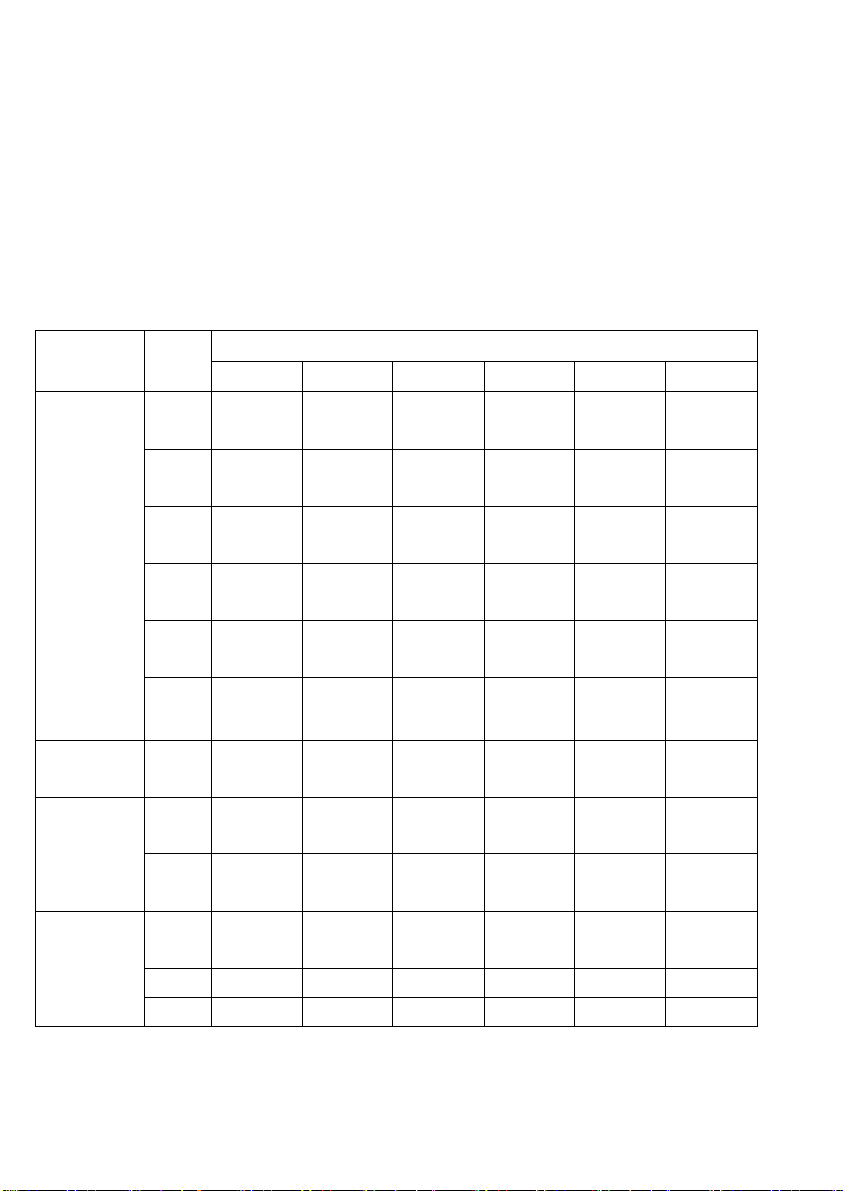

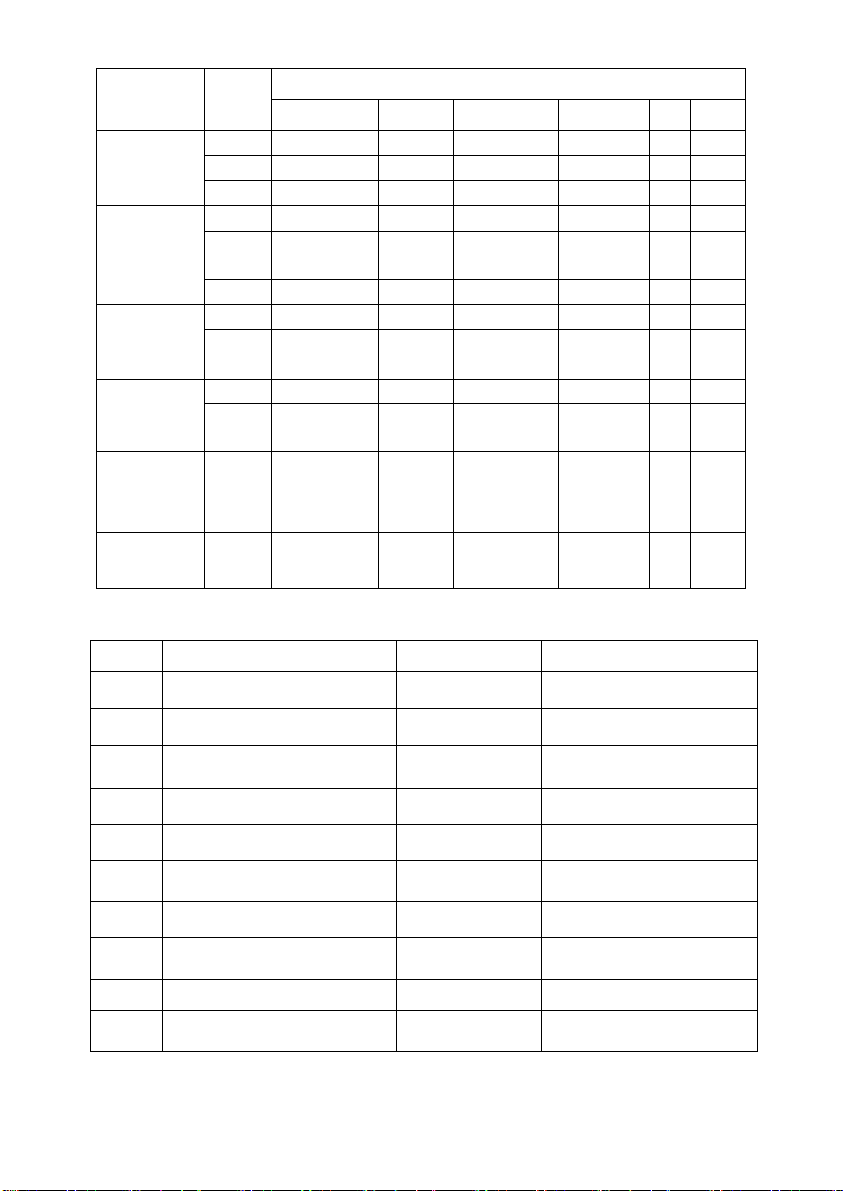

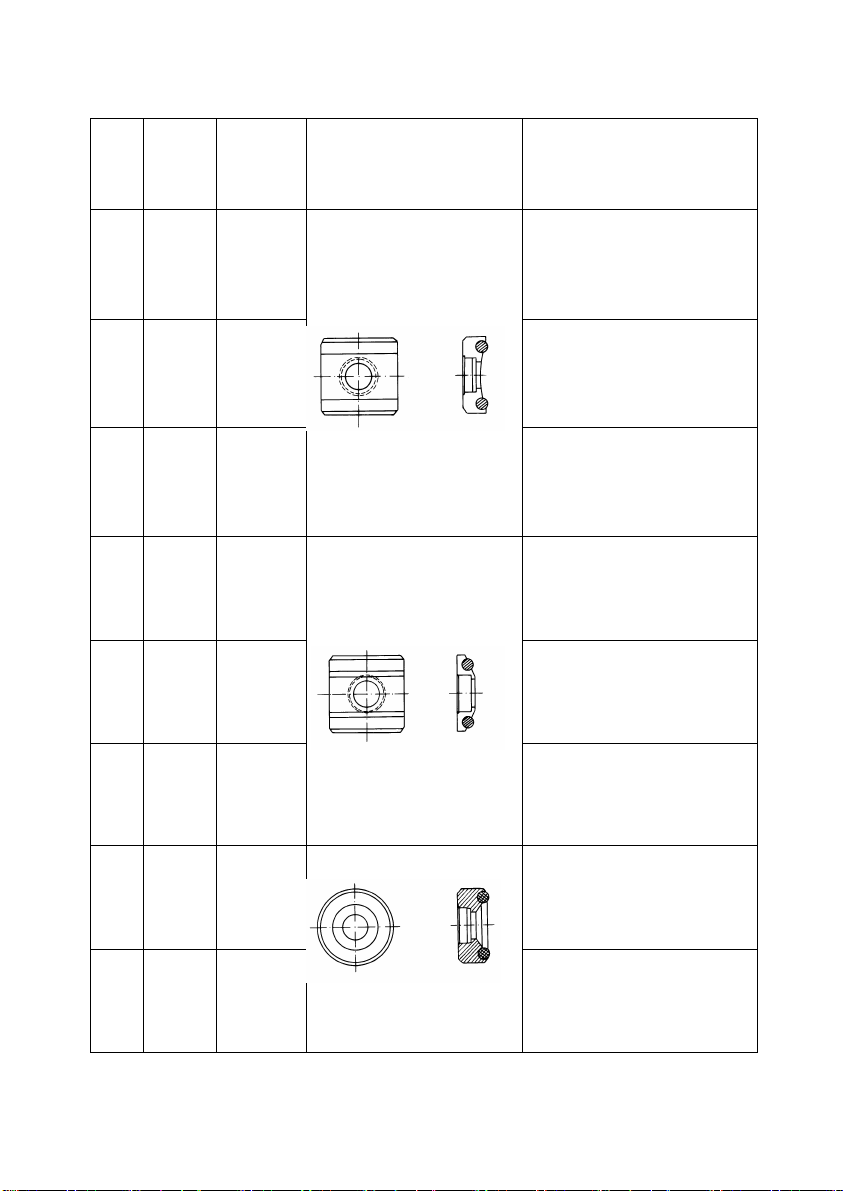

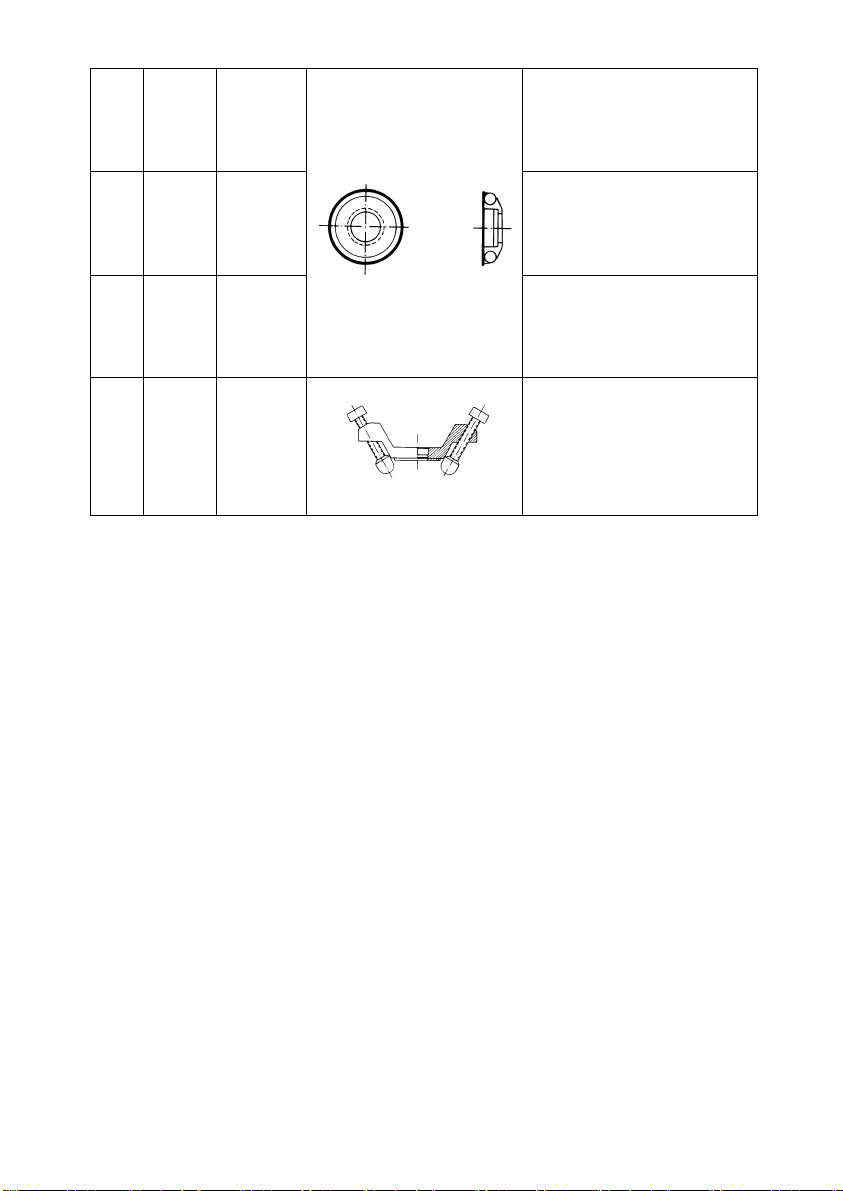

1.3 Types and specification............................................................. 6

1.4 Operating conditions:................................................................ 9

2 Structure features and Testing principle........................... 10

2.1 Structure features.....................................................................10

2.2 Testing principle......................................................................12

3 Technical capabilities ........................................................ 12

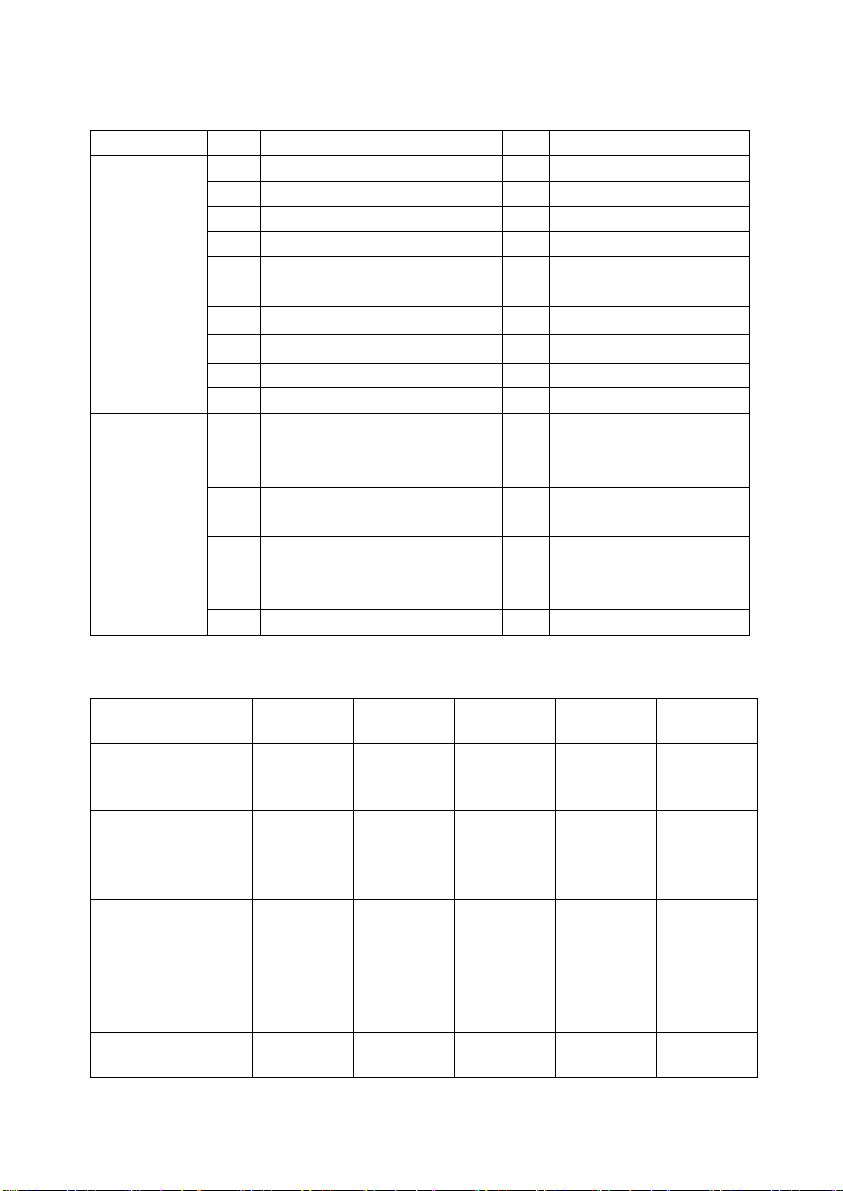

3.1 Specifications..........................................................................12

3.2 Dimension size and weight.......................................................13

4 Testing............................................................................... 13

4.1 Preparation and Inspection prior to testing ................................13

4.2 Testing ....................................................................................15

5 Special prompts................................................................. 18

6 Detail Testing procedures.................................................. 19

6.1 Start-up...................................................................................19

6.2 Turn On or turn off ..................................................................19

6.3 Testing ....................................................................................19

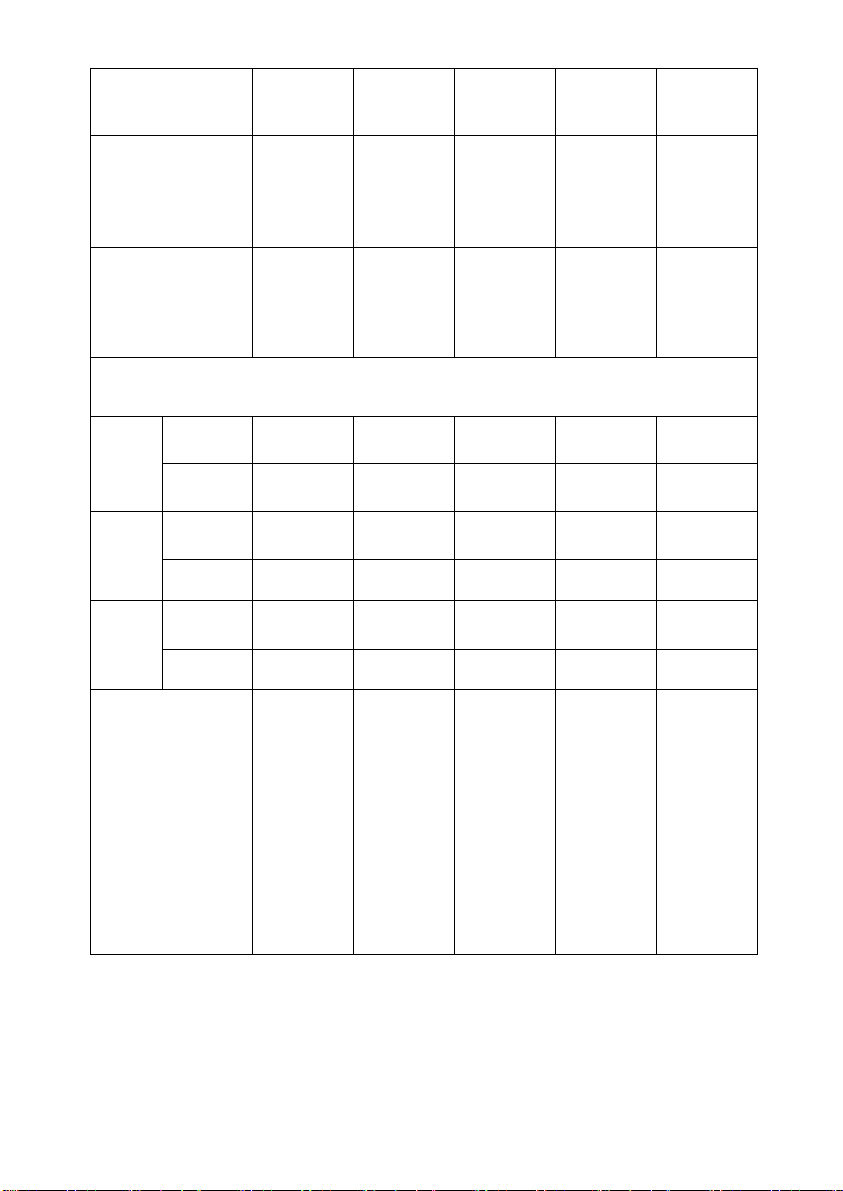

6.4 Menu structure diagram...........................................................22

6.5 Measuring condition setting .....................................................23

6.6 Print function...........................................................................25

6.7 Memory manager ....................................................................27

6.8 System Set ..............................................................................28

6.9 About software ........................................................................28

6.10 Software calibration...............................................................29

6.12 Turn off the power automatically............................................30

6.13 Battery Charge.......................................................................30

6.14 Battery Replacement..............................................................31

6.15 Paper Loading .......................................................................32

6.16 The connection of data communication cable..........................32