2

XP SERIES INVERTERSXP SERIES INVERTERS

XP SERIES INVERTERSXP SERIES INVERTERS

XP SERIES INVERTERS

DC/AC Sine Wave Inverters: 125 - 1100 Watts

Features

• True sine wave output

• Will power all types of loads

• State of the art switched mode design

• High MTBF>180,000 hours

• DC input options: 12V, 24V, 32V, 48V, 66V & 108V

• Frequency options: 50, 60 and 400HZ

• Output options: 100, 120, 230 VAC

• Overload, thermal and overvoltage protection

The XP series inverters provide the best regulated true sine wave

inverters on the market. Reliable, lightweight and with input

options from 12V to 110DC. With distortion of <2%, the XP

inverters are designed to provide smooth, clean, continuous AC

power without noise and spikes which could affect todays high

tech electronic equipment. They will also operate any type of

load, making them the ideal inverter in AC standby power

applications for telecommunications, industrial and other

commercial applications.

Power

XP

1 = 125W (not with 230V)

2 = 250W

6 = 600W

K = 1100W

0 = 100VAC

1 = 120VAC

3 = 230VAC

1 = 12VDC

2 = 24VDC

B = 32VDC

3 = 36VDC

4 = 48VDC

E = 66VDC

I = 110VDC

5 = 50HZ

6 = 60HZ

4 = 400HZ

Input 48VDC

Output 230VAC 50HZ, 600W

Power Code:

Out VAC code:

Input VDC code:

Frequency code:

eg. XP6 - 3 - 4 - 5 =

Model Selection

Frequency

Output VAC Input VDC

12VDC (10.5 - 16.5)

24VDC (21.0 - 33.0)

32VDC (28.0 - 44.0)

48VDC (42.5 - 62.0)

66VDC (58.0 - 91.0)

108VDC (95.0 - 149.0)

Sinusoidal

Typically 1.5%, maximum 2%

100V, 120V or 230VAC options

50HZ, 60HZ or 400HZ options

Regulation ±0.1%

125 to 1100 watts. Refer to table

Typically 2.2 times rated output

(except 125W units and 250W)

Typically 88% at rated load

Typically 0.1% maximum 0.5%

Typically 3% maximum 5%

-25°C to 40°C at rated power

5% to 95% non condensing

-200ft to 10,000ft operating

Less than 45dbA

Convection cooled 125 - 250W models.

Thermostatically controlled forced air

600 - 1100W models

EN55014

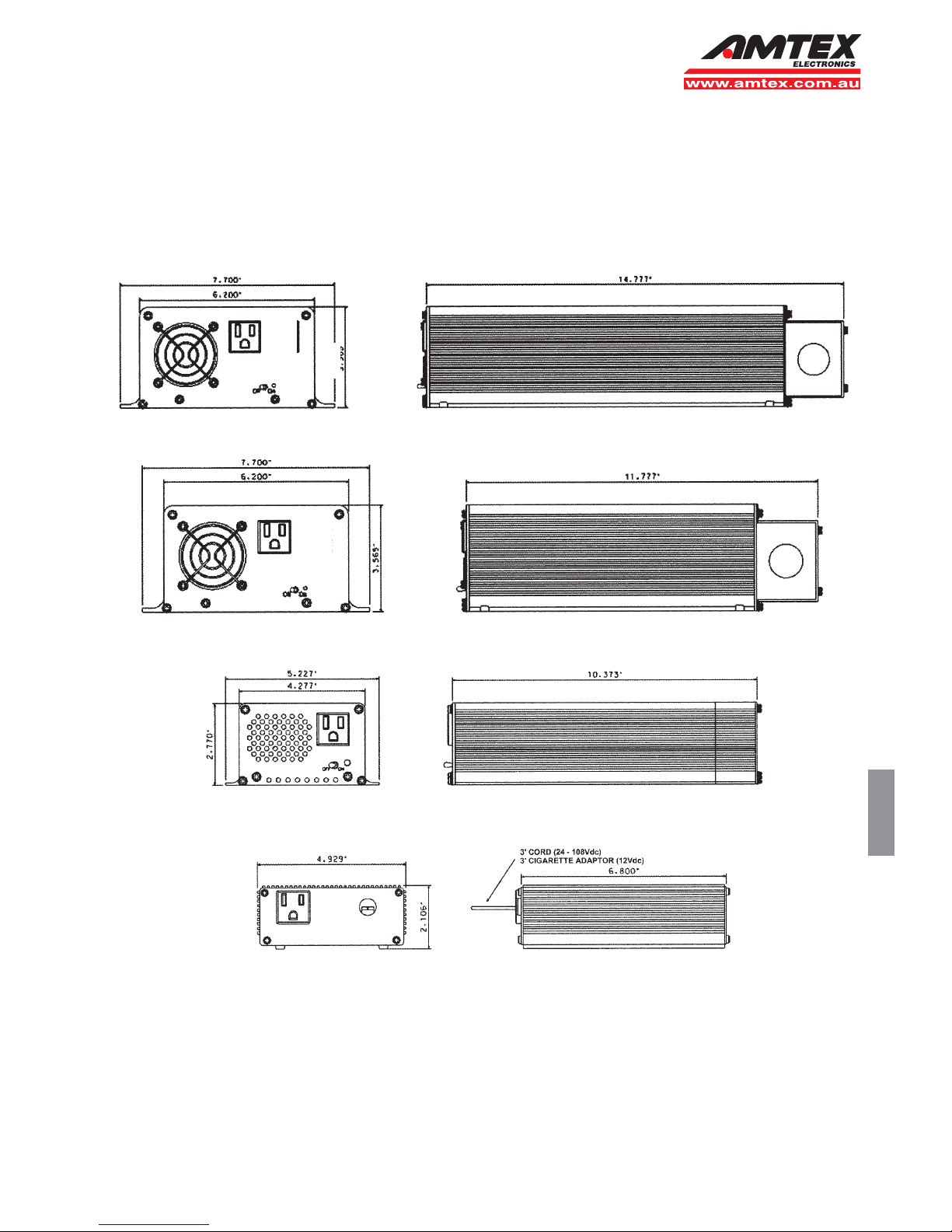

XP125: 118 x 51 x 172mm 0.9kg.

XP250: 265 x 70 x 135mm 3.0kg

XP600: 196 x 92 x 300mm 4.5kg.

XP1100: 196 x 92 x 375mm 4.5kg.

Shutdown at maximum input voltage

condition.

Shutdown at minimum input voltage

condition.

Shutdown at 105°C internal temperature,

warning buzzer at approximately 5°C

before shutdown.

Unit will shutdown in event of output

short.

P190BK050683 - converts IEC output

plug, to Australian plug.

INPUT VOLTAGE:

(Typical range)

AC WAVEFORM:

OUTPUT VOLTAGE:

HARMONIC DISTORTION:

FREQUENCY:

FREQUENCY REG:

OUTPUT POWER:

SURGE POWER:

EFFICIENCY:

REGULATION LINE:

REGULATION LOAD:

OPERATING TEMPERATURE:

HUMIDITY:

ALTITUDE:

AUDIBLE NOISE:

COOLING:

DIMENSIONS (WHD) & WEIGHT:

EMC:

PROTECTION (Automatically reset):

*

Specifications

*OVER VOLTAGE:

*UNDER VOLTAGE:

*THERMAL:

OUTPUT PROTECTION:

OUTPUT CABLE: