For full warranty information, refer to the AMX Instruction Manual(s) associated with your Product(s).

6/13

©2013 AMX. All rights reserved. AMX and the AMX logo are registered trademarks of AMX.

AMX reserves the right to alter specifications without notice at any time.

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 • 800.222.0193 • fax 469.624.7153 • technical support 800.932.6993 • www.amx.com

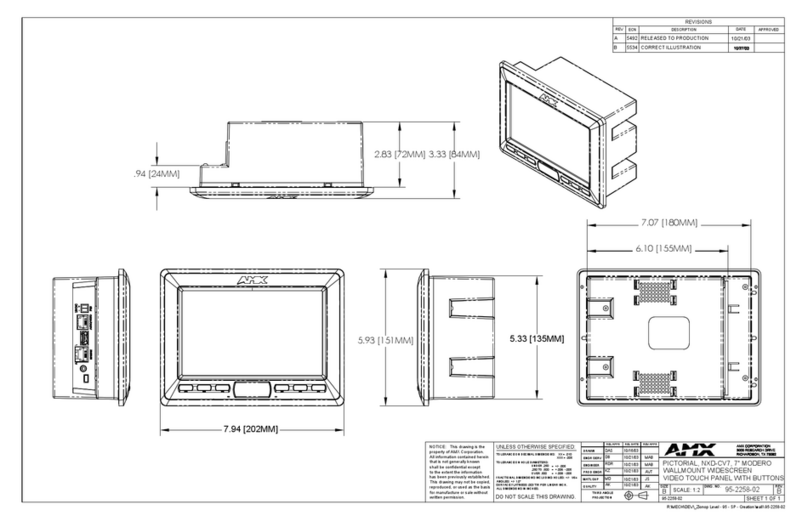

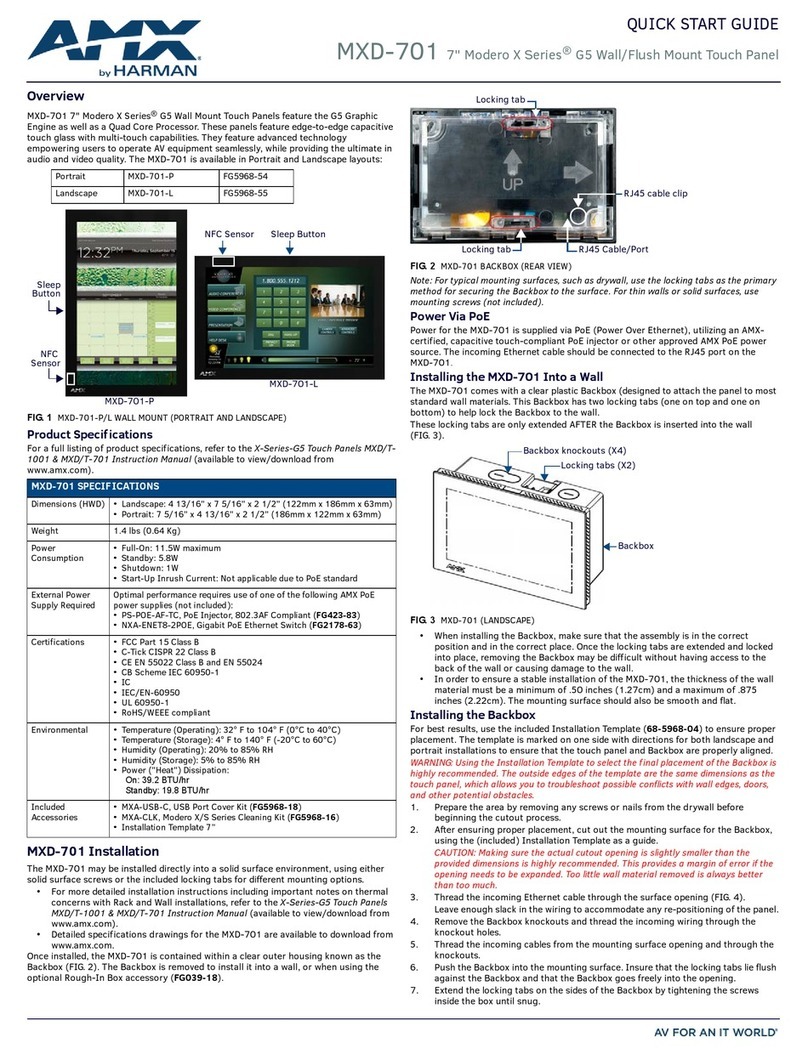

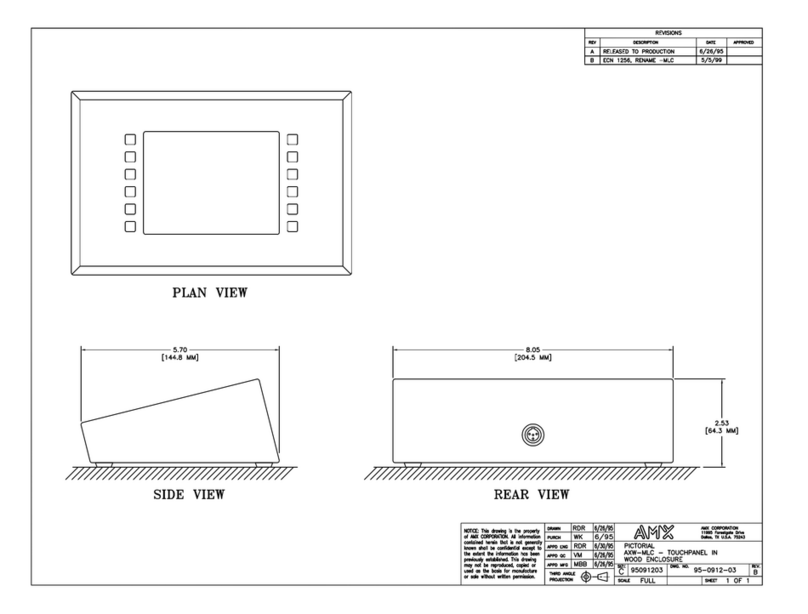

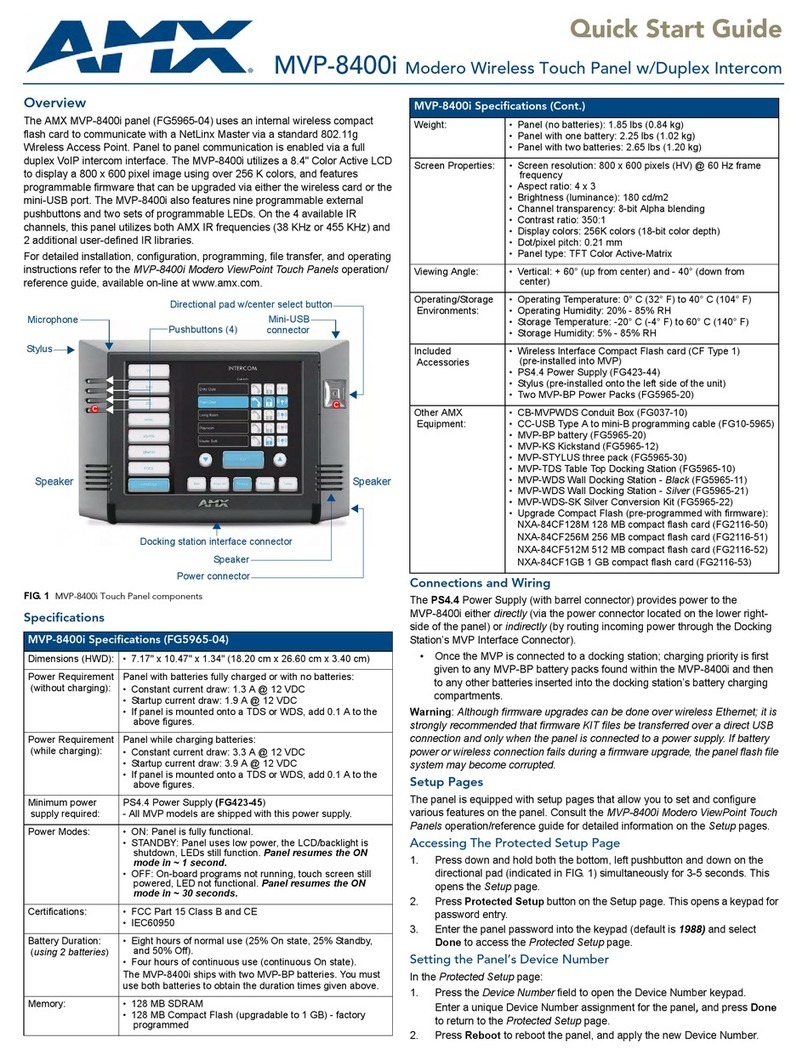

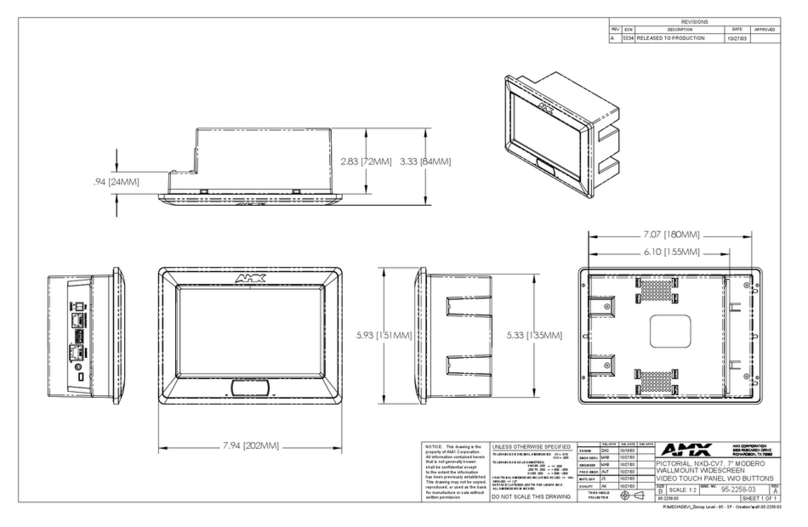

Panel Connectors and Wiring

FIG. 2 shows the main connectors located on the underside of the MXD-1900L-PAN.

The Micro-USB port is used for camera video output. A second, limited access USB

port is accessible on the back side of this cover.

Wiring Guidelines

The MXD-1900L-PAN uses a 12 VDC-compliant power supply to provide power to the

panel via the 2-pin 3.5 mm captive wire PWR connector. Use the previously provided

power requirement information to determine the power draw. The incoming PWR and

GND wires from the power supply must be connected to the corresponding locations

within the PWR connector.

NOTE: Apply power to the panel only after installation is complete.

NOTE: Connecting power to the MXD-1900L-PAN should be done using the included

2-pin 3.5mm captive wire connector included with the device. This connector is

retained within its port with locking screws instead of the pins on each side of standard

captive wire connectors, and using force to insert a standard captive wire connector

may damage the device.

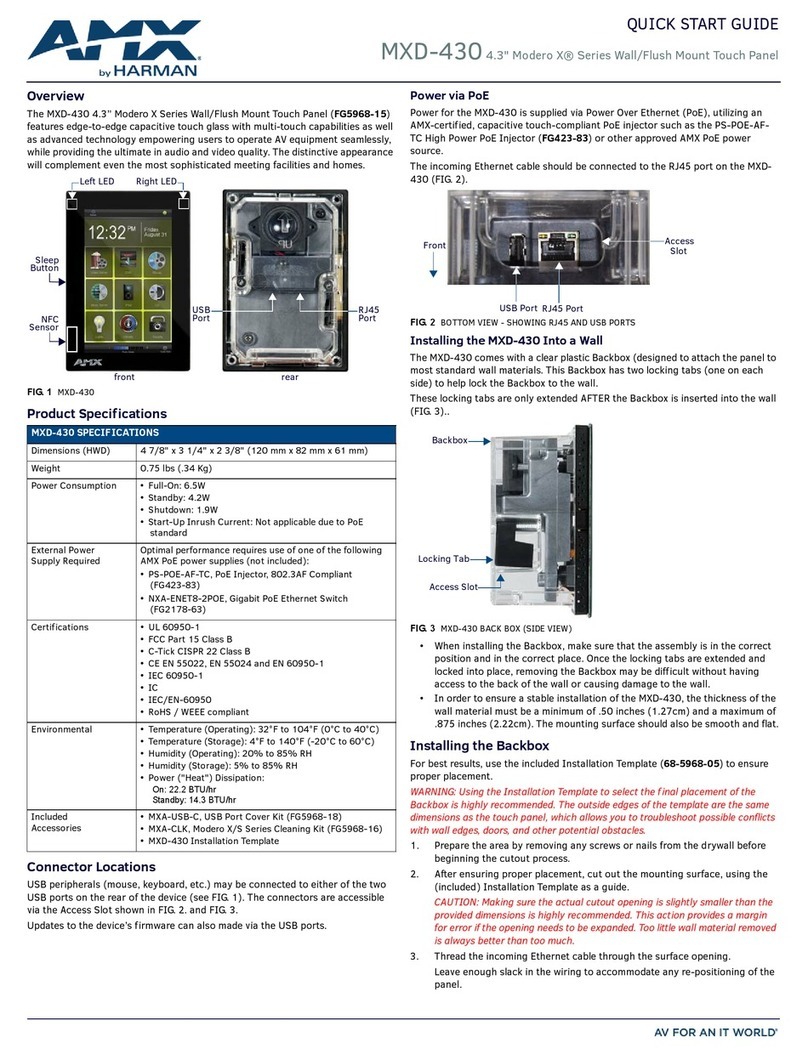

Wiring a Power Connection

To use the 2-pin 3.5 mm captive wire connector with a 12 VDC-compliant power

supply, the incoming PWR and GND wires from the external source must be

connected to their corresponding locations on the connector (FIG. 3). The connector

uses locking screws to insure a connection to the device, so make sure to insert and

tighten the screws before applying power.

1. Insert the PWR and GND wires on the terminal end of the 2-pin 3.5 mm captive

wire connector cable. Match the wiring locations of the +/- on both the power

supply and the terminal connector.

2. Tighten the clamp to secure the two wires. Do not tighten the screws

excessively; doing so may strip the threads and damage the connector.

3. Verify the connection of the 2-pin 3.5 mm captive wire connector to the external

12 VDC-compliant power supply and apply power.

Configuring the MXD-1900L-PAN

The MXD-1900L-PAN is equipped with Settings Pages that allow you to set and

configure various features on the panel. For more information on connecting and

configuring the MXD-1900L-PAN to a network, please refer to the Modero X Series

Programming Guide, available at www.amx.com.

Installing the MXD-1900L-PAN

The MXD-1900L-PAN can be installed either directly into a solid surface environment,

using either solid surface screws or the included locking tabs for different mounting

options. For more information, please refer to the MXD-1900L-PAN Operation/

Reference Guide, available at www.amx.com.

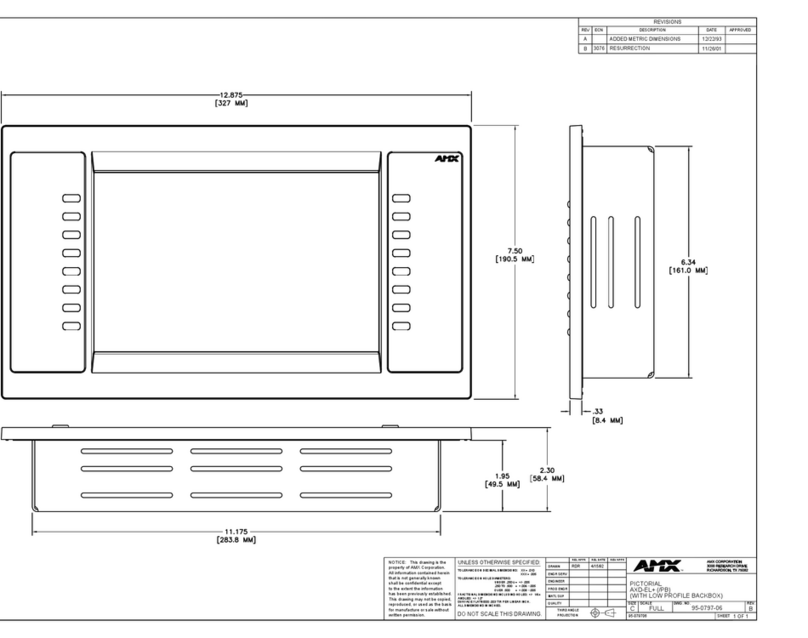

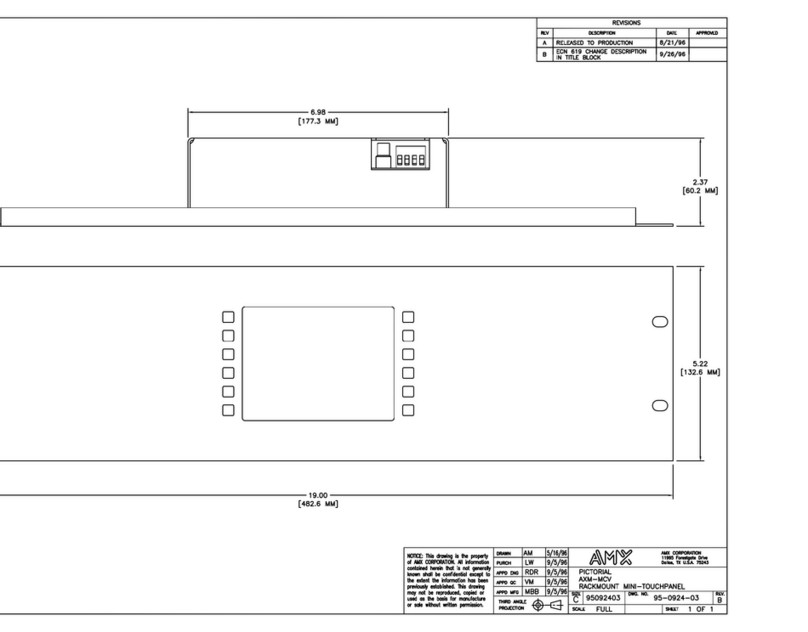

The MXD-1900L-PAN is contained within a clear outer housing known as the back box

(FIG. 4). This back box is removed when installing the deviceinto a wall or when using

the optional Rough-In Box accessory (FG039-15).

Installing the MXD-1900L-PAN into a wall

The MXD-1900L-PAN comes with a clear plastic backbox (FIG. 4) designed to attach

the panel to most standard wall materials. This backbox has four locking tabs (two on

top and two on bottom) to help lock the backbox to the wall. These locking tabs are

only extended AFTER the backbox is inserted into the wall.

WARNING: When installing the backbox, make sure that the assembly is in the

correct position and in the correct place. Once the locking tabs are extended and

locked into place, removing the backbox may be difficult without having access to the

back of the wall or causing damage to the wall.

Note: In order to guarantee a stable installation of the MXD-1900L-PAN, the thickness

of the wall material must be a minimum of .50 inches (1.27cm) and amaximum of .875

inches (2.22cm).

WARNING: The maximum recommended torque to screw in the locking tabs on the

plastic back box is 5 IN-LB [56 N-CM]. Applying excessive torque while tightening the

tab screws, such as with powered screwdrivers, can strip out the locking tabs or

damage the plastic back box.

1. Prepare the area by removing any screws or nails from the drywall before

beginning the cutout process.

2. Since the cutout for the back box is off-center from the edges of the touch panel, use

the MXD-1900L-PAN Installation Template (68-5968-02) to ensure proper placement.

3. Cut out the surface for the back box. Refer to the dimensions in the MXD-1900L-

PAN Operation/Reference Guide, available from www.amx.com, for more

information.

CAUTION: Making sure that the actual cutout opening is slightly smaller than the

provided dimensions is highly recommended. This action provides the installer with a

margin for error if the opening needs to be expanded. Too little wall material removed

is always better than too much.

4. Thread the incoming power, Ethernet, and Micro-USB wiring (if Micro-USB

access is desired) from their terminal locations through the surface opening.

Leave enough slack in the wiring to accommodate any re-positioning of the

panel.

5. Push the back box into the wall opening. Insure that the locking tabs lie flush

against the back box.

6. Extend the locking tabs on the sides of the back box by tightening the screws

inside the box until snug. Not all of the tabs must be extended to lock the back

box in place, but extending a minimum of the top and bottom tabs is highly

recommended. Apply enough pressure to the screw head to keep the box flush

with the wall: this ensures that the locking tabs will tighten up against the inside

of the wall.

The back box is clear to allow visual confirmation that the tabs have been

extended and are gripping the wall, as well as in assisting with removal if

necessary.

7. For additional strength, #4 mounting screws (not included) may be secured

through circular holes located at the left and right sides of the MXD-1900L-PAN.

In order to prevent damage to the touch panel, make sure that these are flush

with the back box.

8. Insert each connector into its corresponding location along the back of the

device.

9. Test the incoming wiring by attaching the panel connections to their terminal

locations and applying power. Verify that the panel is receiving power and

functioning properly to prevent repetition of the installation.

NOTE: Do not disconnect the connectors from the touch panel. The unit must be

installed with the attached connectors before being inserted into the drywall.

10. Insert the four temporary mounting posts of the panel (FIG. 4) into the openings

on the back box and slide the panel onto the back box. This will temporarily hold

the panel during the rest of the installation.

WARNING: When installing the panel, do NOT press on or near the center of the panel. Too

much stress at the center may damage the touch screen surface. When installing the panel,

pressure should be applied toward the ends of the panel ONLY.

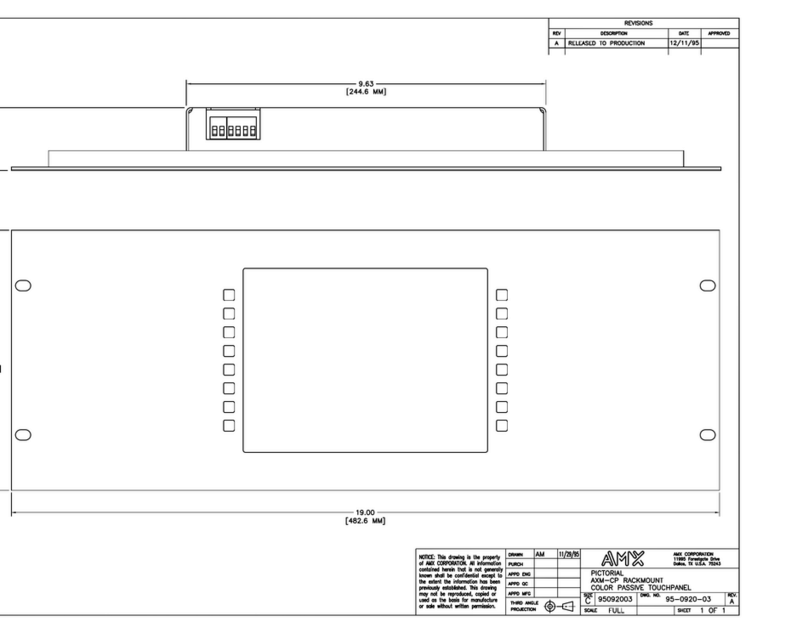

11. Use the six provided screws, three at each end, to secure the touch panel to the

back box (FIG. 5). Use only the provided screws, as other screws may damage

the touch panel.

12. Snap the decorative side covers onto each end of the touch panel.

13. Reconnect the terminal Ethernet and USB to their respective locations on either

the Ethernet port or NetLinx Master.

FIG. 2 Panel connectors

FIG. 3 NetLinx power connector wiring diagram

Ethernet 10/100

Port Micro-USB

Port

USB Port

12 VDC

Power Port

Top

(landscape

mode) Limited

access

USB

port

PWR +

GND -

To the Touch Panel

Power Supply

FIG. 4 MXD-1900L-PAN backbox

FIG. 5 Installing screws and side cover

Locking Tabs

Locking Tabs

Temporary Mounting Posts

Temporary Mounting Posts

Touch panel

Screws

Side cover