Anaheim Automation DPMLP601 User manual

1

#L010168 January 2005

DPMLP601DPMLP601

DPMLP601DPMLP601

DPMLP601

Programmable Driver PackProgrammable Driver Pack

Programmable Driver PackProgrammable Driver Pack

Programmable Driver Pack

User’s GuideUser’s Guide

User’s GuideUser’s Guide

User’s Guide

910 East Orangefair Lane, Anaheim, CA 92801

website: www.anaheimautomation.com

ANAHEIM AUTOMATION, INC.ANAHEIM AUTOMATION, INC.

ANAHEIM AUTOMATION, INC.ANAHEIM AUTOMATION, INC.

ANAHEIM AUTOMATION, INC.

2

#L010168 January 2005

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

Section 1: IntroductionSection 1: Introduction

Section 1: IntroductionSection 1: Introduction

Section 1: Introduction ..................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................

......................................................................................................................................... 33

33

3

Description .............................................................................................................................................................. 3

Electrical Specifications ........................................................................................................................................... 4

OrderingInformation................................................................................................................................................ 4

Dimensions/SwitchLocations .................................................................................................................................. 5

Wiring Diagrams ...................................................................................................................................................... 5

Terminal Descriptions - Power................................................................................................................................. 6

Terminal Descriptions - Driver ................................................................................................................................. 6

Terminal Descriptions - Controller ........................................................................................................................... 7

Connector Descriptions - Controller......................................................................................................................... 7

Slide Switch Descriptions - Controller...................................................................................................................... 7

Section 2: Driver FunctionsSection 2: Driver Functions

Section 2: Driver FunctionsSection 2: Driver Functions

Section 2: Driver Functions ....................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................

.................................................................................................................................. 88

88

8

Motor Selection........................................................................................................................................................ 8

Step Motor Current Setting Guide............................................................................................................................ 8

Microstep Selection (SW1 Settings) ........................................................................................................................ 9

Setting the Output Current....................................................................................................................................... 9

Reducing Output Current....................................................................................................................................... 10

Determining Output Current................................................................................................................................... 10

Step Motor Configurations ..................................................................................................................................... 10

Connecting the Step Motor .................................................................................................................................... 12

Short-Circuit, Mis-Wire, and Over-Current Conditions ........................................................................................... 12

Over-Temperature and Over-Voltage Conditions .................................................................................................. 12

Section 3: Controller FunctionsSection 3: Controller Functions

Section 3: Controller FunctionsSection 3: Controller Functions

Section 3: Controller Functions ..................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................

......................................................................................................................... 1313

1313

13

Methods of Communication ................................................................................................................................... 13

Baud Rate ............................................................................................................................................................. 13

RS232 Protocol - SW1 in RS232 position.............................................................................................................. 13

RS485 Protocol - SW1 in RS485 position............................................................................................................. 13

Axis Selection ........................................................................................................................................................ 14

Controller Status LED ............................................................................................................................................ 14

Technical Support.................................................................................................................................................. 14

Section 4: SMC60WIN SoftwareSection 4: SMC60WIN Software

Section 4: SMC60WIN SoftwareSection 4: SMC60WIN Software

Section 4: SMC60WIN Software ..................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................

......................................................................................................................... 1919

1919

19

File Menu............................................................................................................................................................... 20

Setup Menu ........................................................................................................................................................... 20

Setup - Axis Menu ................................................................................................................................................. 20

Program Menu....................................................................................................................................................... 21

Program - Autostart Program Menu....................................................................................................................... 21

Edit Menu .............................................................................................................................................................. 21

Help Menu ............................................................................................................................................................. 22

“The Unit is Connected” / “The Unit is NOT Connected”........................................................................................ 22

Toolbar .................................................................................................................................................................. 23

Tab Sheets ............................................................................................................................................................ 23

Tab Sheets - Real Time Motion ............................................................................................................................. 24

Tab Sheets - Encoder Options and Registration Inputs ......................................................................................... 25

Tab Sheets - Analog Input and Thumbwheel Options............................................................................................ 26

Tab Sheets - Create and Edit Program.................................................................................................................. 27

Add/Change/InsertCommands ............................................................................................................................. 28

Add Tab Sheets - Motion Commands.................................................................................................................... 29

Add Tab Sheets - If/Then and Output Commands ................................................................................................. 30

Add Tab Sheets - Goto, For Loops, Encoder and Thumbwheel Commands ......................................................... 31

Add Tab Sheets - Analog, Registration and Text Commands................................................................................ 32

Calculator .............................................................................................................................................................. 33

Section 5: Direct Talk ModeSection 5: Direct Talk Mode

Section 5: Direct Talk ModeSection 5: Direct Talk Mode

Section 5: Direct Talk Mode................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................

................................................................................................................................3434

3434

34

Section 6: TroubleshootingSection 6: Troubleshooting

Section 6: TroubleshootingSection 6: Troubleshooting

Section 6: Troubleshooting ................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................

................................................................................................................................4444

4444

44

Error Codes ........................................................................................................................................................... 45

Section 7: Sample ProgramsSection 7: Sample Programs

Section 7: Sample ProgramsSection 7: Sample Programs

Section 7: Sample Programs ............................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................

.............................................................................................................................. 4646

4646

46

Appendix 1: ASCII Table for Direct Mode .............................................................................................................. 51

3

#L010168 January 2005

Section 1: IntroductionSection 1: Introduction

Section 1: IntroductionSection 1: Introduction

Section 1: Introduction

The DPMLP601 is a single-axis 8A, 160V motor bus voltage, bipolar microstep motor driver with a control-

ler containing 2 Kbytes of nonvolatile stored programming space and quadrature encoder feedback pack-

age. It provides flexible, independent control of bipolar step motors with a current range from 1.5 to 8.0

amps/phase and a fixed microstepping resolution of 1000 steps per revolution from a computer, or any

machine controller with a serial port. With an input voltage of 90-132 VAC (50/60Hz), no external power

supplies or transformers are needed. It is also capable of stand-alone operation, making it an embedded

machine controller. The easy to use Windows software, SMC60WIN, can be used to directly control

motion and to program the DPMLP601. The DPMLP601 also has the ability for real time functions.

The DPMLP601 has 40 commands, which are easy-to-remember for direct movement of the step motor

and communicates via either an RS232 or RS485 bidirectional serial data bus. Up to 99 DPMLP601’s can

be networked from one communications port on your PC or PLC, utilizing the RS485 communications

protocol. Special functions of the controller include 8 programmable open collector outputs and 6 TTL,

CMOS and 24V compatible inputs, a quadrature encoder input with the ability to autocorrect, an analog

input to control either maximum speed or absolute position, registration mark indexing during a slew

command, an output that will trigger during an index command at an absolute position, and a thumbwheel

input for indexing a motor. The DPMLP601 can be powered from 90-132 VAC, 50/60Hz,

DescriptionDescription

DescriptionDescription

Description

The driver in the DPMLP601 (MLP08641) is a microstep motor driver that can drive motors rated from 1.5

to 8.0 amps/phase. It has a fixed mictrostepping resolution of 1000 steps per revolution. It can handle 4,

6and8-leadmotors inabipolarfashion. TheDPMLP601’sdriver featuresmotorcurrentON/OFFcapabilities

and a Reduced Current Enable to automatically reduces motor current to 50% of the set value after the

last step is made (1sec delay). Protection devices have been added to this driver for short circuit, open

circuit, over voltage, under voltage and over temperature conditions. The driver has built-in features to

indicate power on (Green LED), Clocks being received (Yellow LED) and fault conditions (Red LED).

Thecontrollerin theDPMLP601(PCL601) providesindependentprogramming ofacceleration/deceleration,

base speed (start up speed), max speed (running speed), jog speed, and the number of steps to be taken

in both relative and absolute positioning modes. On absolute positioning moves, the DPMLP601

automaticallydetermines theproperdirection togo andthe numberofstepstotake. Therelative positioning

will move a number of steps in the direction that the user defines. The DPMLP601 also has specific

functions such as

encoder feed back, autocorrection, index-on-the-fly and output-on-the-fly

. An analog

input can be used to set either the maximum speed or goto an absolute position based between the upper

and lower programmable limits. A seven decade thumbwheel switch can be read for relative indexing. The

DPMLP601also has ahigh levelprogramming command setthat includes:branching, looping, conditional

statements, time delays, text strings, and I/O which the user can use in the programming mode to fully

control all machine functionality. A home input, a set of bidirectional hard and soft limit switch inputs and

bidirectional jog inputs are provided for each axis. These features are generally required in most machine

control designs. 6 testable TTL, CMOS and 24V compatible inputs and 8 programmable open-collector

outputs are provided per axis. The I/O may be used for monitoring and controlling machine operation and/

or interaxis coordination. The I/O are accessible independent of the busy state of the axis controls. The

DPMLP601 has a built-in programmable reset circuit. Reset is automatic on power-up, or by pressing the

external reset button.

4

#L010168 January 2005

Electrical SpecificationsElectrical Specifications

Electrical SpecificationsElectrical Specifications

Electrical Specifications

Power Requirements:Power Requirements:

Power Requirements:Power Requirements:

Power Requirements:

90-132 VAC 50/60Hz

Operating Temperature:Operating Temperature:

Operating Temperature:Operating Temperature:

Operating Temperature:

0 to 60 degrees C

Pulse Output Range:Pulse Output Range:

Pulse Output Range:Pulse Output Range:

Pulse Output Range:

1 to 50,000 Hz

10uS negative going pulse width

Inputs (TTL-CMOS):Inputs (TTL-CMOS):

Inputs (TTL-CMOS):Inputs (TTL-CMOS):

Inputs (TTL-CMOS):

Logic “0”: 0 to 0.8VDC

Logic “1”: 3.5 to 24VDC

Analog input 1: 0 to 5VDC

Output Current Rating:Output Current Rating:

Output Current Rating:Output Current Rating:

Output Current Rating:

8 A/phase maximum

Baud Rate:Baud Rate:

Baud Rate:Baud Rate:

Baud Rate:

38400 Baud, Fixed

Data Format:Data Format:

Data Format:Data Format:

Data Format:

Half-Duplex, 1 start bit, 8 data bits,

no parity, 1 stop bit

Outputs (8 programmable I/O and fault out):Outputs (8 programmable I/O and fault out):

Outputs (8 programmable I/O and fault out):Outputs (8 programmable I/O and fault out):

Outputs (8 programmable I/O and fault out):

Open Drain Type

40V, 100mA

+5VDC Output, 50mA

Output1 active time for output on the fly:Output1 active time for output on the fly:

Output1 active time for output on the fly:Output1 active time for output on the fly:

Output1 active time for output on the fly:

50uS

Note:Note:

Note:Note:

Note: For inductive loads, customers must connect

a clamping diode to protect from flyback voltage

spikes.

rebmuNtraP noitpircseD

106PLMPD egatlovsubrotomV061htiwevirdralopibpma8aserutaeF-kcaPevirD/rellortnoC

10601NPD ylppusrewopdnaevirdralopibpma01aserutaeF-kcaPevirD/rellortnoC

10657DPD ylppusrewopdnaevirdralopinupma7aserutaeF-kcaPevirD/rellortnoC

BT9DS584retrevnoc584SRot232SR

7SWT 106PLMPDhtiwelbitapmochctiwsleehwbmuhtnoitisopneveS

6-CFM9AA .rotcennocelamef9BDenodnaelam9BDenohtiwelbaclaireshguorhtthgiartstoof6

Ordering InformationOrdering Information

Ordering InformationOrdering Information

Ordering Information

Thetable belowlists avariety of productsavailable fromAnaheim Automation,Inc. Theseproducts include

those covered by this manual, along with supporting cables and devices. We are continually adding new

products to our line, so please consult Anaheim Automation, Inc. or its representatives for information on

the latest releases.

A CD, provided when you purchase the unit, contains this user’s manual, along with the SMC60WIN

software and DPMLP601 program examples. The software allows you to write and change programs that

are to be stored in the DPMLP601 for autostart use, and also upload the program that is stored in the

DPMLP601 itself for editing and viewing. The software also allows you to save the programs onto your

computer hard drive, and easily retrieve them when needed.

5

#L010168 January 2005

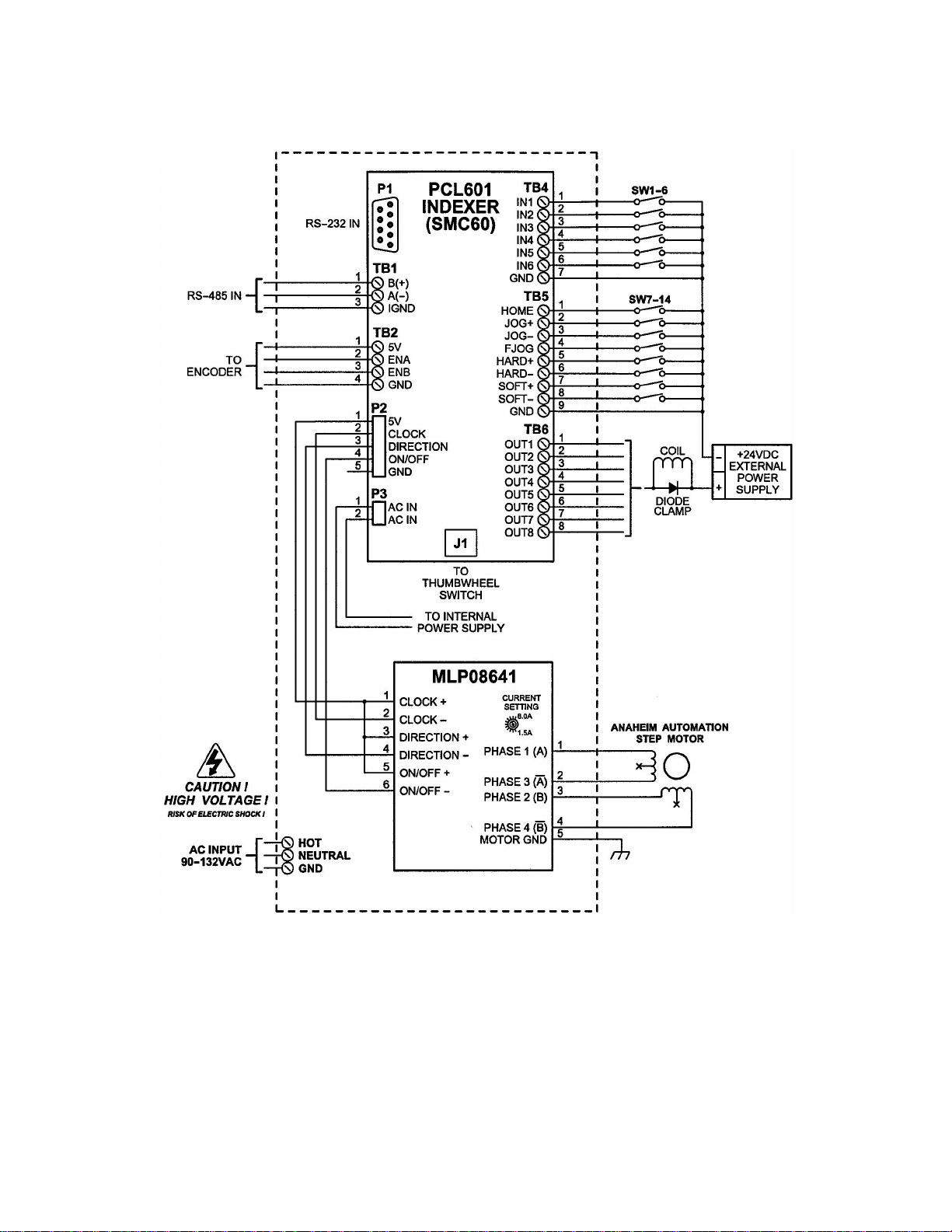

Wiring/Hook-up DiagramWiring/Hook-up Diagram

Wiring/Hook-up DiagramWiring/Hook-up Diagram

Wiring/Hook-up Diagram

Table of contents

Other Anaheim Automation Industrial Equipment manuals