Advanced Preparations:

• Be familiar with the controls of the range hood by reading through

Range Hood Operations,

Page 15.

• Place the range hood on a flat, stable surface. Connect the range hood to a designated standard outlet (120-

Volt,60Hz, AC only) and turn on the range hood. Verify all operations of the range hood by referring

to

Range

Hood Operations

.

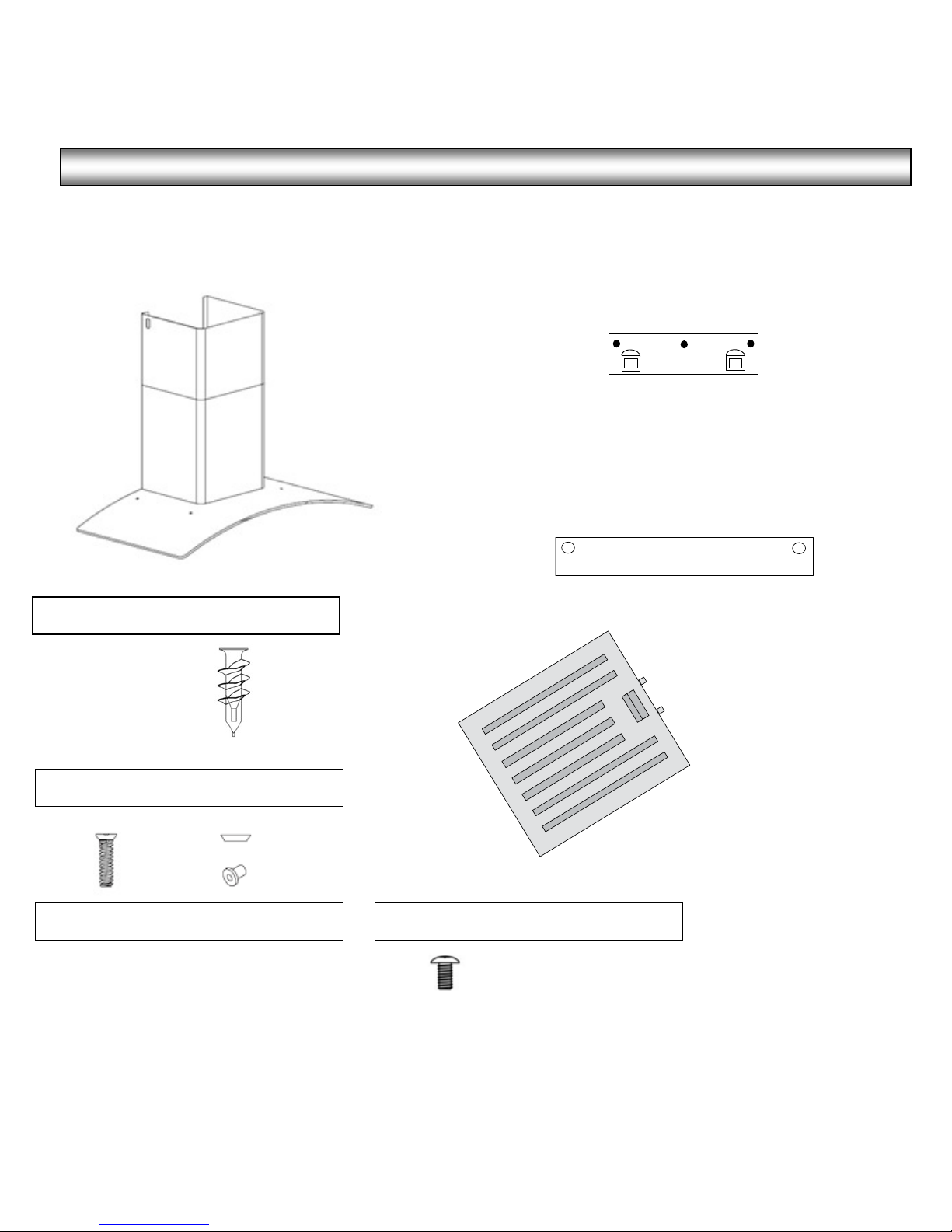

• Place all supplied parts and required hardware on a flat, stable surface and verify the existence of all

supplied parts listed on Page 4.

Preparations:

NOTE: To avoid damage to your hood, prevent debris from entering the vent opening.

• Determine and mark the center line on the ceiling where the range hood will be installed. Make sure

there is proper clearance within the ceiling or wall for exhaust vent.

• Due to the weight and size of this unit, please make sure that the support system or framework being

used is stable and secure in the wall.

• Put a thick, protective covering over counter top, cook top or range to protect from damage or dirt.

Remove any hazardous objects around the area when installing.

CAUTION

If moving the cooking range is necessary to install the hood, turn OFF the power on an electric range at

the main electrical box. SHUT OFF THE GAS BEFORE MOVING A GAS RANGE

Operations:

• Read and understand all instructions and warnings in this manual before operating the appliance. Save these instructions

for future reference.

• Always leave safety grills and filters in place. Without these components, operating blowers could catch on to hair, fingers

and loose clothing.

• NEVER dispose cigarette ashes, ignitable substances, or any foreign objects into blowers.

• NEVER leave cooking unattended. When frying, oil in the pan can easily overheat and catch fire. The risk of self

combustion is higher when the oil has been used several times.

• NEVER cook on “open” flames under the range hood. Check deep-fryers during use: Superheated oil may be flammable.

Cleaning:

• The saturation of greasy residue in the blower and filters may cause increased inflammability. Keep unit clean and free of

grease and residue build-up at all times to prevent possible fires.

• Filters must be cleaned periodically and free from accumulation of cooking residue (see cleaning

Instructions on Page 22). Old and worn filters must be replaced immediately.

• DO NOT operate blowers when filters are removed. Never disassemble parts to clean without proper

instructions. Disassembly is recommended to be performed by qualified personnel only. Read and

understand all instructions and warnings in this manual before proceeding

SAFETY WARNING: Never put your hand into area housing the fan while the fan is operating!

For optimal operation, clean range hood and all baffle/spacer/filter/grease tunnel/oil container regularly. Regular

care will help preserve the appearance of the range hood.

Cleaning Exterior surfaces:

• Clean periodically with hot soapy water and clean cotton cloth. DO NOT use corrosive or abrasive detergent (e.g.

Comet Power Scrub®, EZ-Off® oven cleaner), or steel wool/scoring pads, which will scratch and damage the stainless

steel surface. For heavier soil use liquid degrease such as “Formula 409®” or “Fantastic®” brand cleaner.

• If hood looks splotchy (stainless steel hood), use a stainless steel cleaner to clean the surface of the hood. Avoid getting

cleaning solution onto or into the control panel. Follow directions of the stainless steel cleaner. CAUTION: DO NOT

leave on too long as this may cause damage to hood finish. Use soft towel to wipe off the cleaning solution, gently rub

off any stubborn spots. Use dry soft towel to dry the hood.

• After cleaning, you may use non abrasive stainless steel polish such as 3M® or ZEP®, to polish and buff out the stainless

luster and grain. Always scrub lightly, with clean cotton cloth, and with the grain.

• DO NOT allow deposits to accumulate or remain on the hood.

• DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the surface and cause rusting.

• DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain in contact with stainless steel for

extended periods. Many of these compounds contain chemicals, which may be harmful. Rinse with water after ex- posure

and wipe dry with a clean cloth.

Cleaning Stainless Steel Baffle Filter:

IMPORTANT: Drain oil from baffles, spacers, filters, oil tunnels, oil containers before oil and residue overflow!

• Remove all baffles, spacers, filters, grease tunnel, and oil containers and discard oil and residue.

• Wash with warm soapy water.

NOTE: Stainless steel baffles, spacers and oil tunnel are top rack dishwasher safe.

• Dry thoroughly before replacing and follow directions for installation in reverse.

• Filters should be cleaned after every 30 hours of use

.

Replacing Filters

:

•

Should filters wear out due to age and prolonged use, replace with following part number

: