Contents

1.Important safety instructions .............................................................................4

2.Introduction ....................................................................................................5

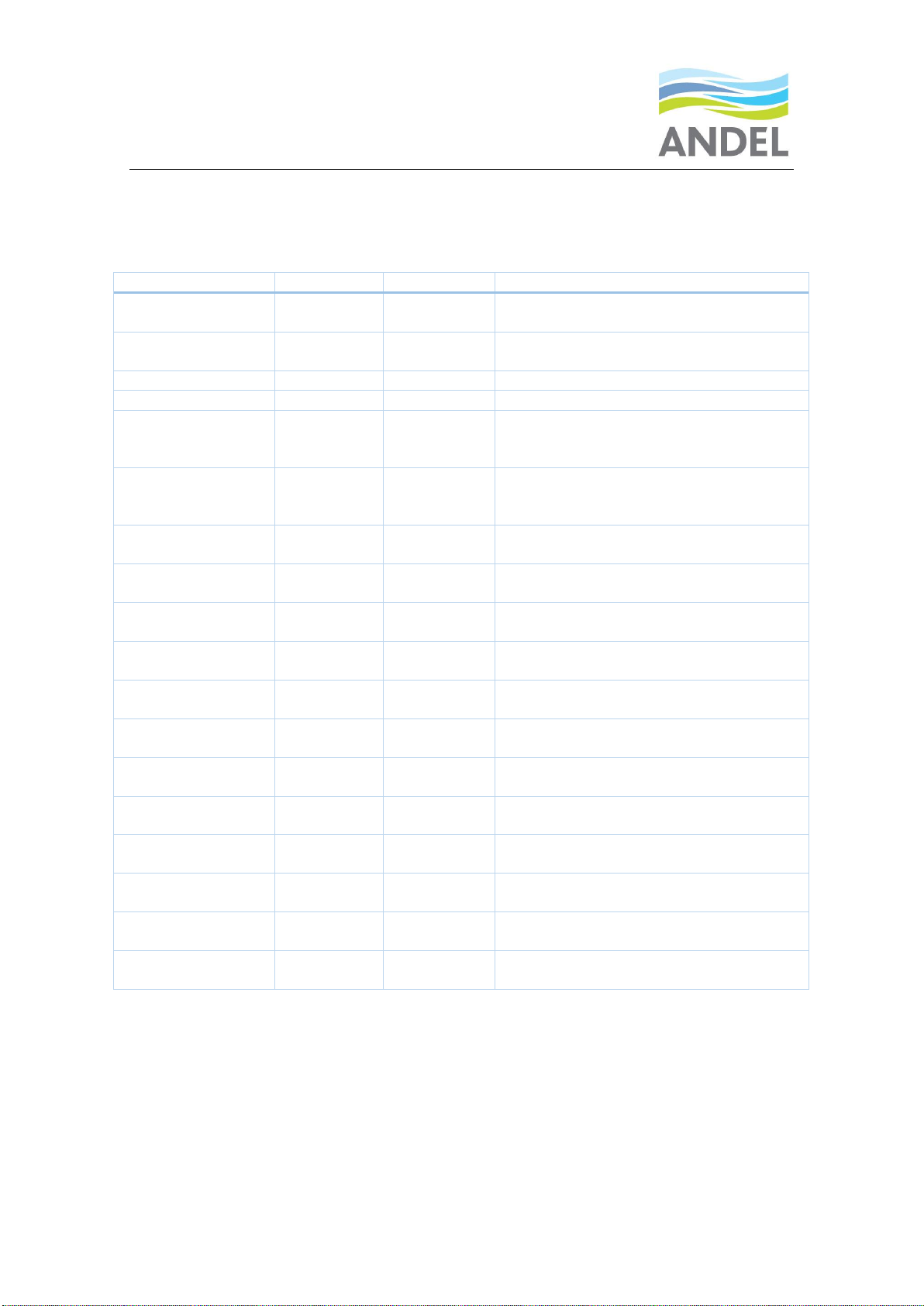

2.1 Available Models .................................................................................................... 6

2.2 Alarms....................................................................................................................7

2.3.1 Control Panel.......................................................................................................8

2.3.2 Bundguard Issue 3A Sensor / Pumps Unit.............................................................9

2.3.2.1 Sensor Unit ..................................................................................................... 10

2.3.2.2 Ebara Best One Submersible Pump .................................................................. 10

2.3.2.3 Fixing Kit ......................................................................................................... 10

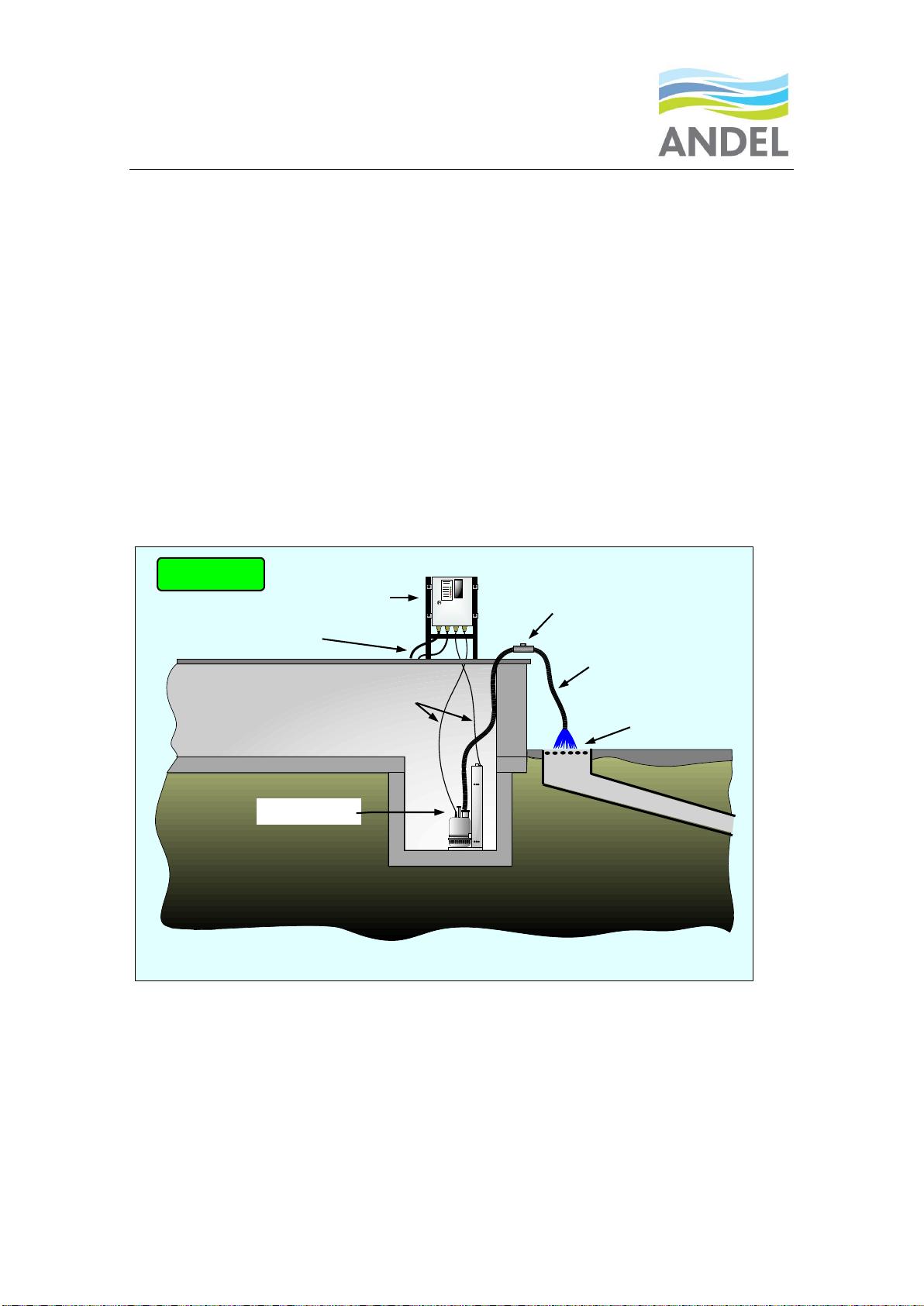

3. Installation....................................................................................................11

3.1 Control Panel Mounting ........................................................................................ 11

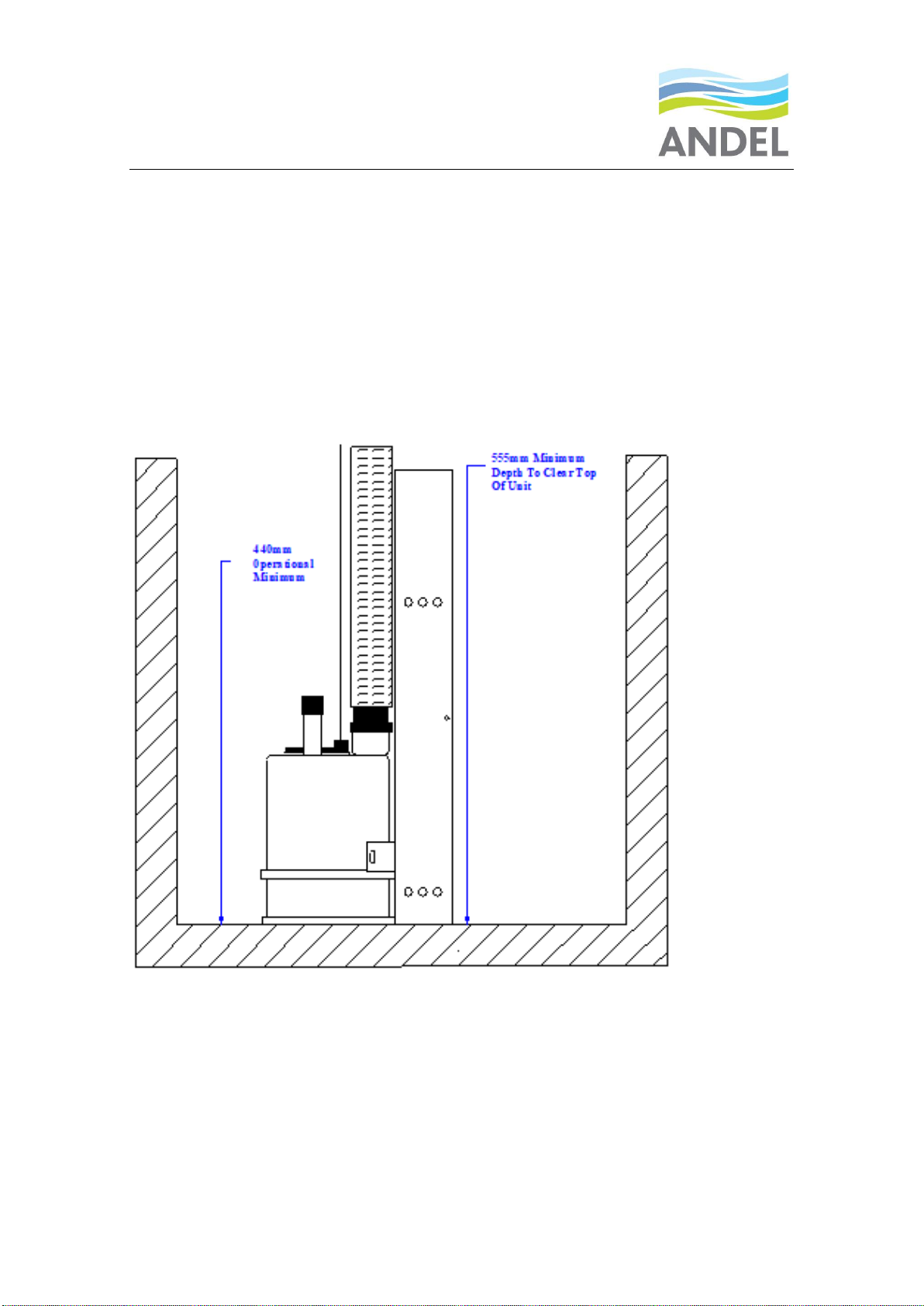

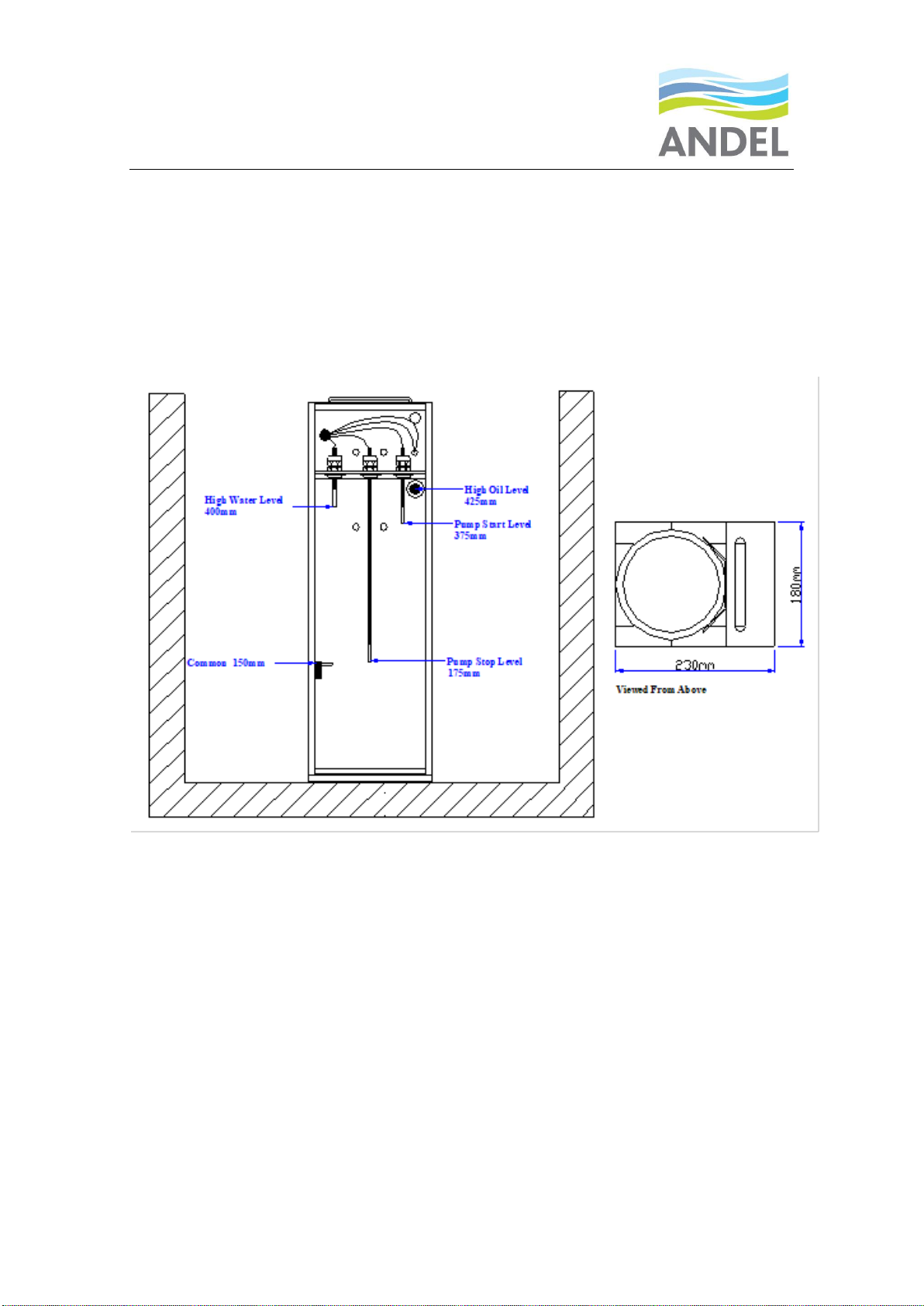

3.2 Sensor and Pump Mounting.................................................................................. 11

3.3 Panel & Sensor Connections.................................................................................. 12

4. System Setup ................................................................................................13

4.1 Installer Menu Operation...................................................................................... 14

4.1.1 Setting Date/Time.............................................................................................. 14

4.1.2 Setting Number of Pumps .................................................................................. 14

4.1.3 Set Current Trip Threshold ................................................................................. 14

4.1.4 Setting Auto-Changeover ................................................................................... 14

4.1.5 High Water Delay............................................................................................... 14

4.1.6 View Current (pump current reading) ................................................................. 14

4.1.7 Setting Overcurrent Trip..................................................................................... 14

4.1.8 Setting Pump Switching Delay ............................................................................ 15

4.1.9 MODBUS............................................................................................................ 15

4.1.10 Floating Paint Values........................................................................................ 15

4.1.10.1 Registers....................................................................................................... 16

4.1.10.2 Discrete inputs .............................................................................................. 16