II

CONTENT

1 SAFETY.....................................................................................................................................................1

1.1 SIGNAL EXPLANATION............................................................................................................................ 1

1.2 ARC WELDING DAMAGE........................................................................................................................ 1

1.3 THE KNOWLEDGE OF ELECTRIC AND MAGNETIC FIELDS................................................................................5

2 SUMMARY...............................................................................................................................................6

2.1 BRIEF INTRODUCTION............................................................................................................................ 6

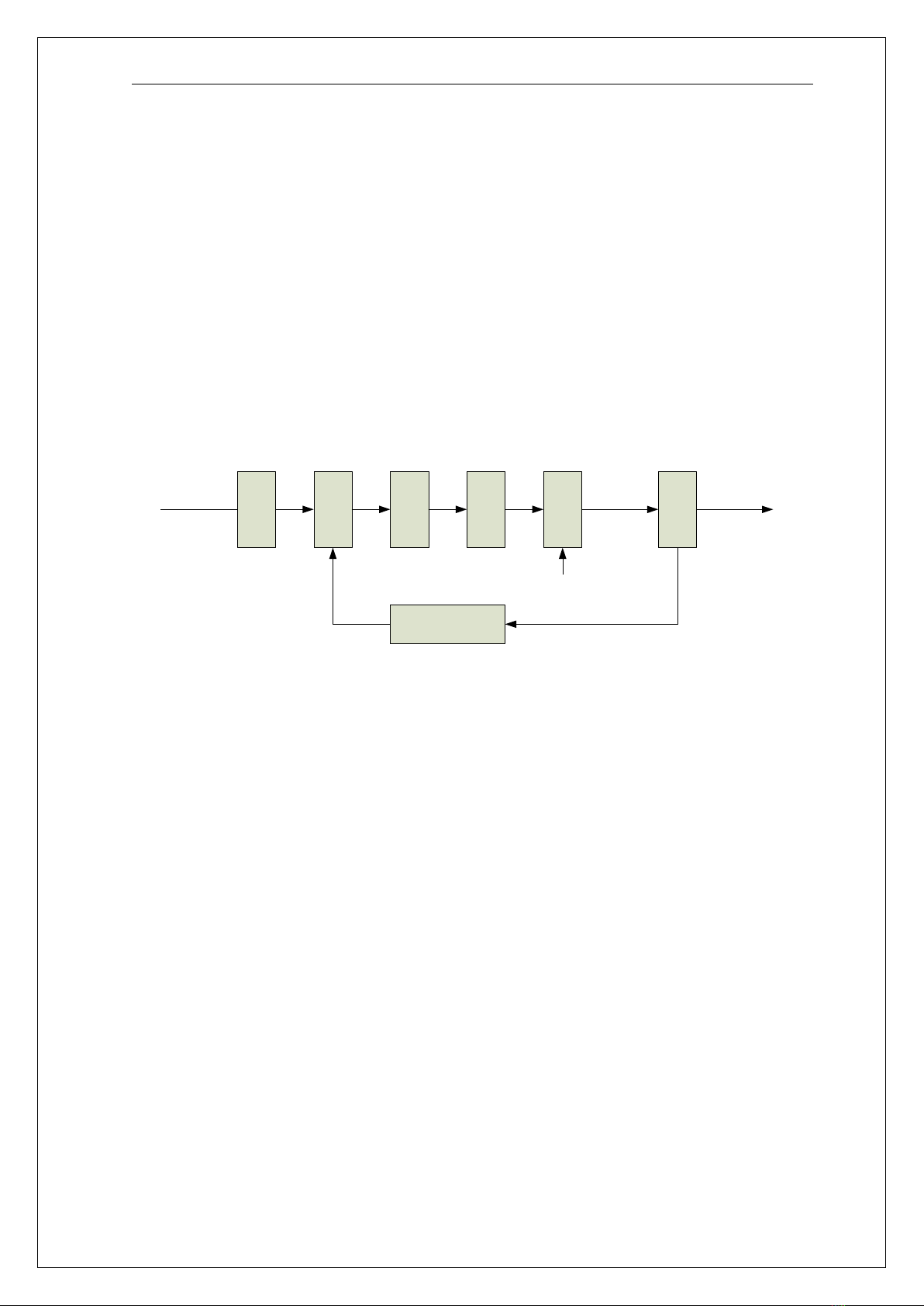

2.2 MODULE EXPLANATION..........................................................................................................................7

2.3 WORKING PRINCIPLE............................................................................................................................. 8

2.4 VOLT-AMPERE CHARACTERISTIC...............................................................................................................8

3 INSTALLATION AND ADJUSTMENT......................................................................................................... 9

3.1 PARAMETERS........................................................................................................................................9

3.2 DUTY CYCLE & OVER HEAT....................................................................................................................10

3.3 MOVEMENT AND PLACEMENT............................................................................................................... 11

3.4 POWER SUPPLY INPUT CONNECTION....................................................................................................... 11

3.5 ASSEMBLING THE EQUIPMENT (TIG)...................................................................................................... 12

4 OPERATION........................................................................................................................................... 13

4.1 LAYOUT FOR THE PANEL........................................................................................................................13

4.2 CONTROL PANEL................................................................................................................................. 14

4.4 ARGON ARC WELDING OPERATION........................................................................................................19

4.4 TIG welding (2T operation)........................................................................................................ 19

4.5 WELDING PARAMETERS........................................................................................................................21

4.5.1 Joint forms in TIG.................................................................................................................... 21

4.5.2 The explanation of welding quality.........................................................................................21

4.5.3 TIG Parameters Matching....................................................................................................... 21

4.6 OPERATION ENVIRONMENT...................................................................................................................24

4.7 OPERATION NOTICES........................................................................................................................... 25

5 MAINTENANCE & TROUBLESHOOTING................................................................................................25

5.1 MAINTENANCE................................................................................................................................... 25

5.2 TROUBLESHOOTING............................................................................................................................. 26

5.3 ELECTRICAL PRINCIPLE DRAWING............................................................................................................30

6 EXPLOSIVE DRAWING........................................................................................................................... 31