2

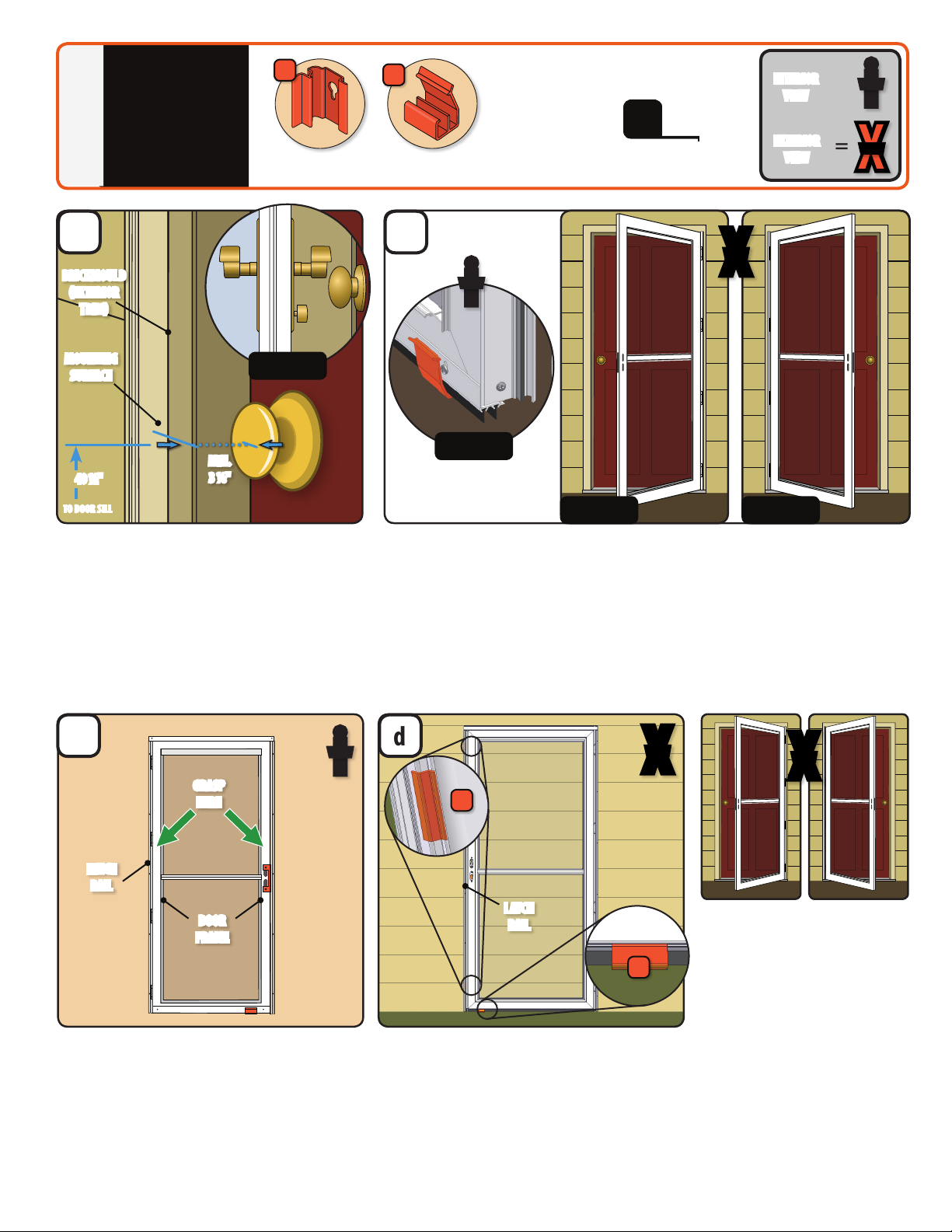

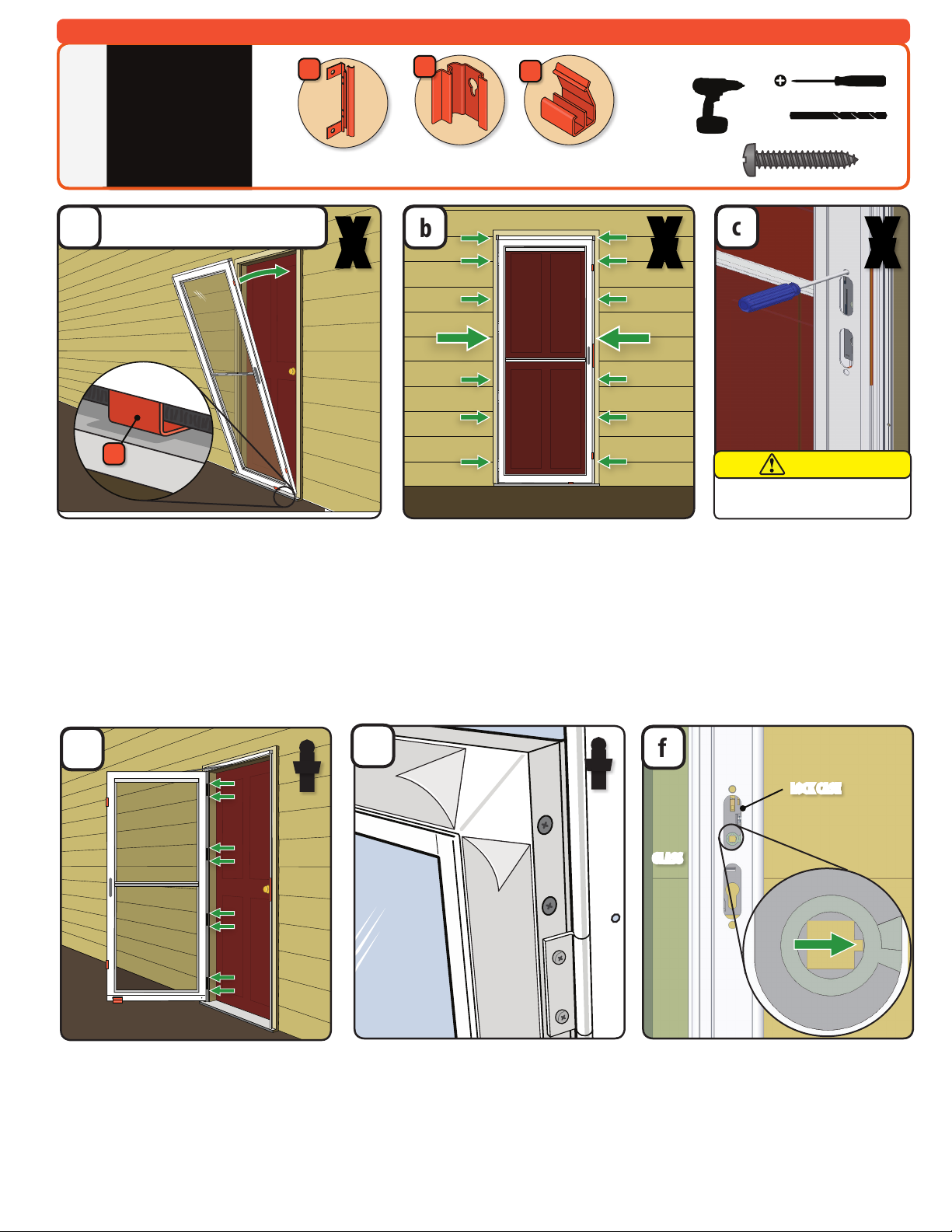

To install the storm door, you must verify that the opening width, height and mounting surface

are suitable size to properly install into the opening.

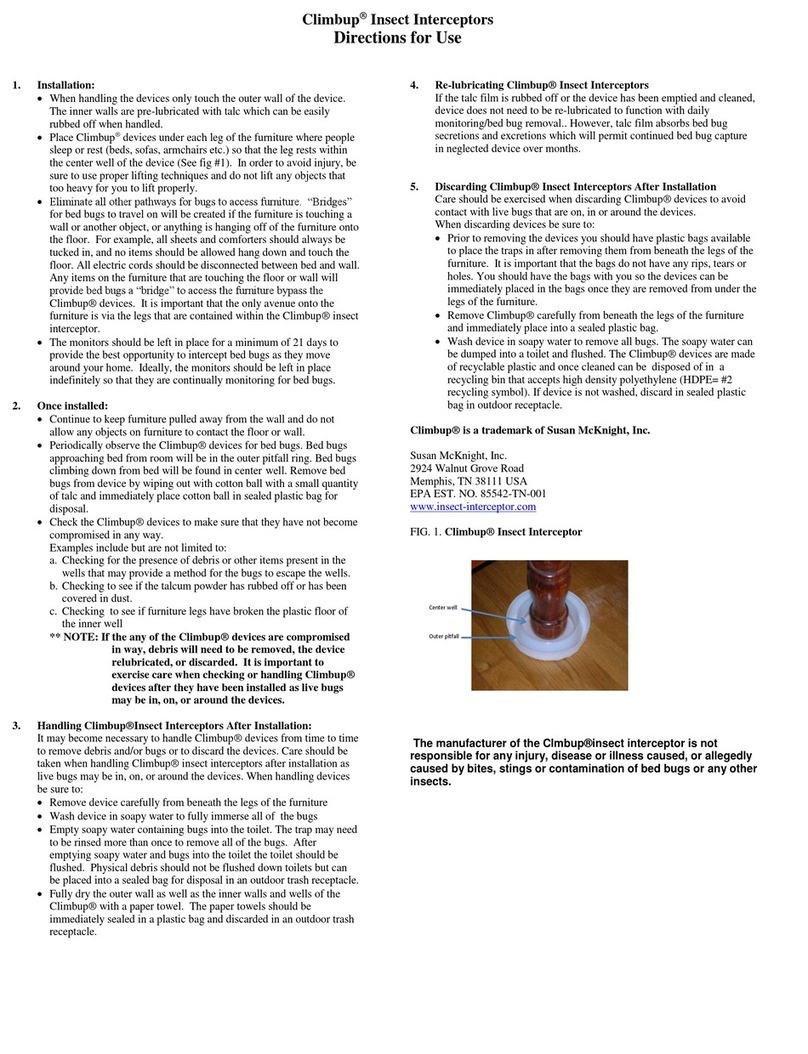

1. Measure the width at the top (W1), middle (W2), and bottom (W3) of the opening (see Figure 1).

Measure from the inside of the exterior trim. Utilizing the narrowest width, reference chart below.

2. Measure the height at the left and right of the opening, from the bottom of the exterior trim at the

top of opening down to the sill at the bottom of opening. Reference chart for height compliance.

Nominal Storm Door Widths*Opening Widths Opening Heights

36"x 80"35 ⁄" – 36 ⁄" 80" (80" – 80 ⁄")

34"x 80"33 ⁄" – 34 ⁄" 80" (80" – 80 ⁄")

32"x 80"31 ⁄" – 32 ⁄" 80" (80" – 80 ⁄")

30"x 80"29 ⁄" – 30 ⁄" 80" (80" – 80 ⁄")

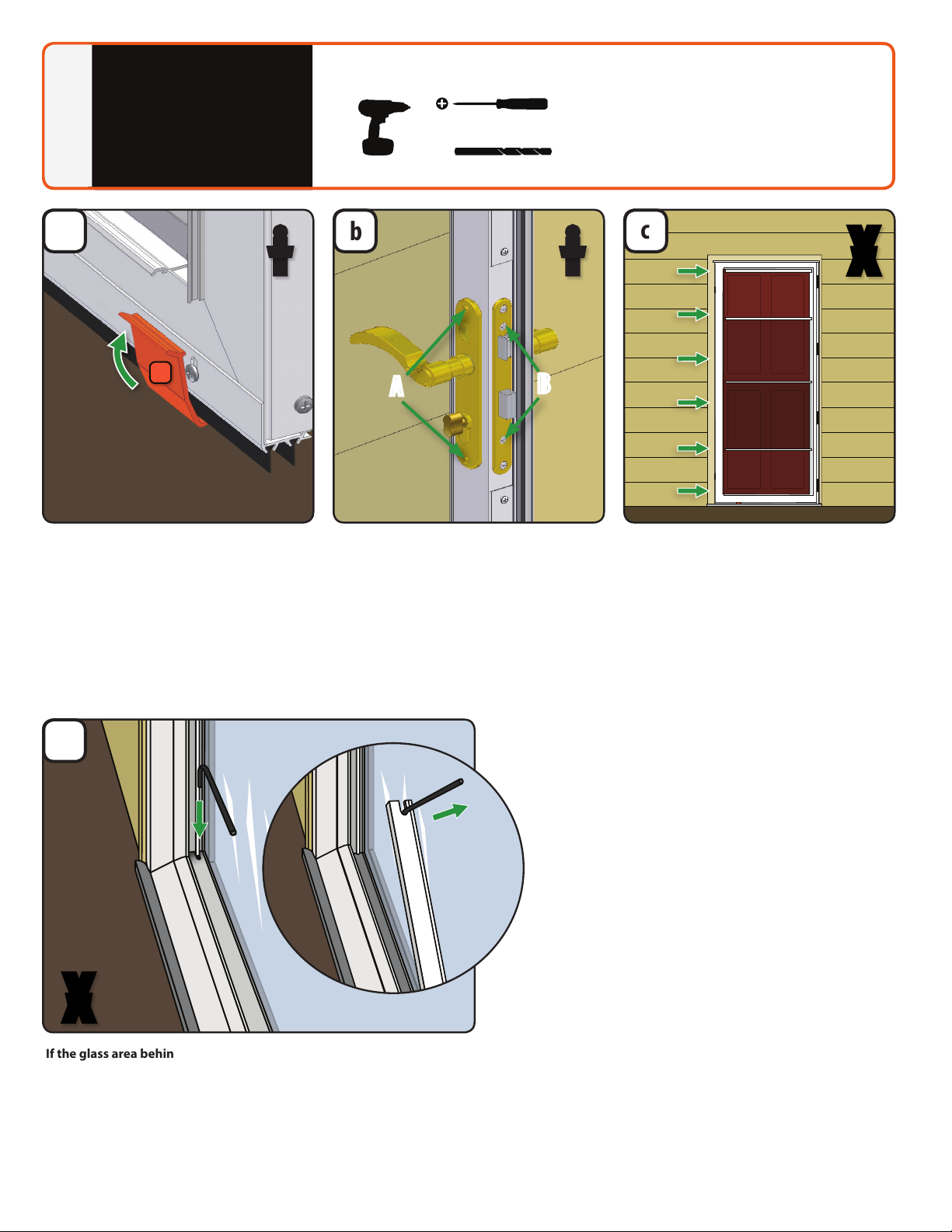

3. Make sure that the exterior trim meets the mounting surface requirements. The assembly needs

a minimum of ¾" at surface on exterior trim face, 1" minimum depth of mounting surface (see

Figure 2). A minimum depth of 3 ⁄ inches for storm door handle clearance. (see Figure 3).

• ¾" minimum at surface on exterior trim face (see Figure 2)

• 1" minimum depth of mounting surface (see Figure 2)

• minimum depth of 3 ⁄ inches for storm door handle clearance (see Figure 3)

If your opening does not t within these dimensions, call the Solution Center at 1-800-933-3626,

as there may be a solution that will work for your opening. .

* Nominal storm doors sizes are listed. The actual storm door frame width and height will be less.

Example: A nominal size of 36” x 80” may have an actual storm door frame size of 35 ⁄” x 79 ⁄”.

Figure 1

W3

H1H1

W2

W1

Figure 2

Figure 3

1"MIN DEPTH

3 ⁄"MIN DEPTH

3/4"MIN

FLAT SURFACE

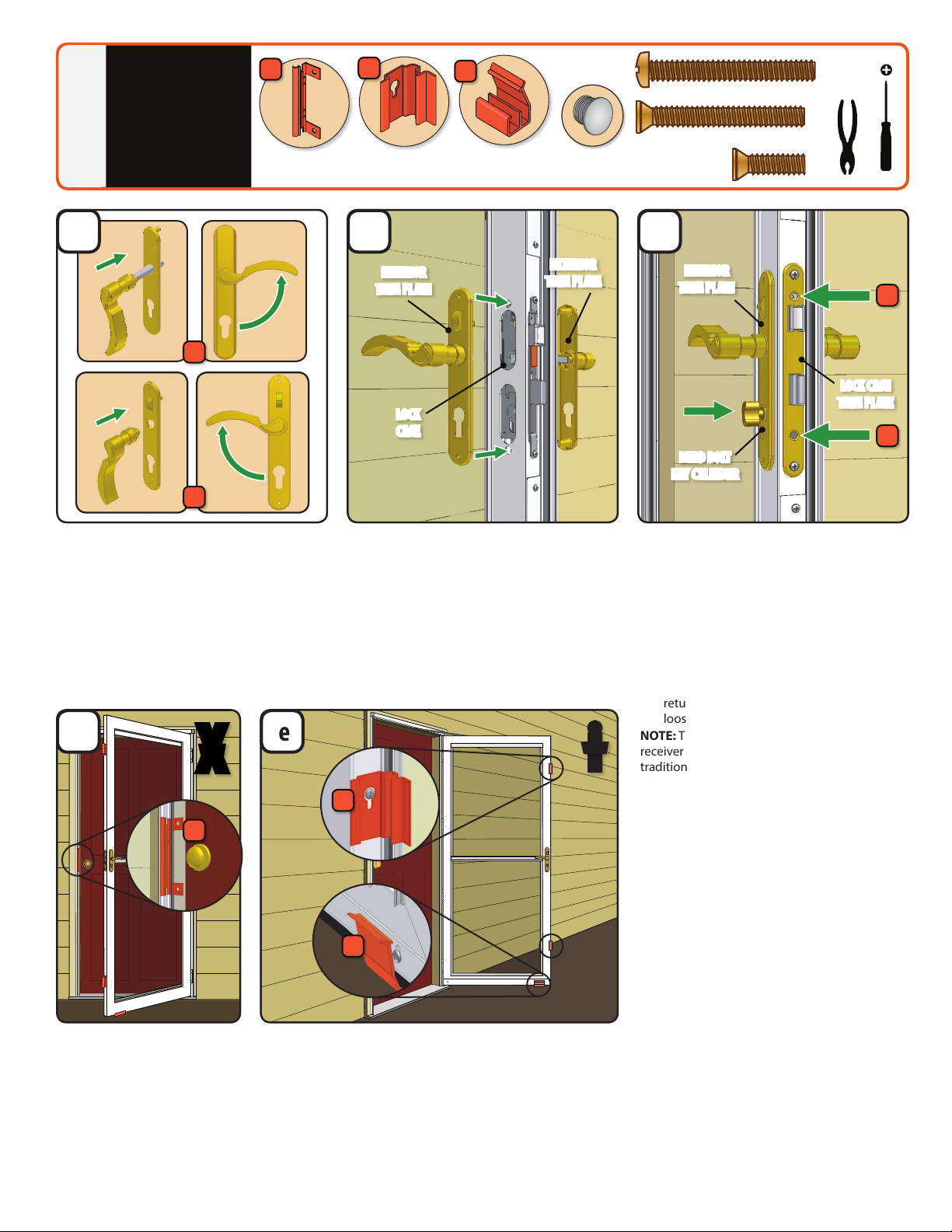

Verify that the exterior brickmould, trim board or casing (exterior trim) is rmly attached to the opening

structure and is a material that is suitable to suciently fasten the storm door to the door opening. The

storm door will sag over time if the mounting surface is not suciently fastened to the entryway.

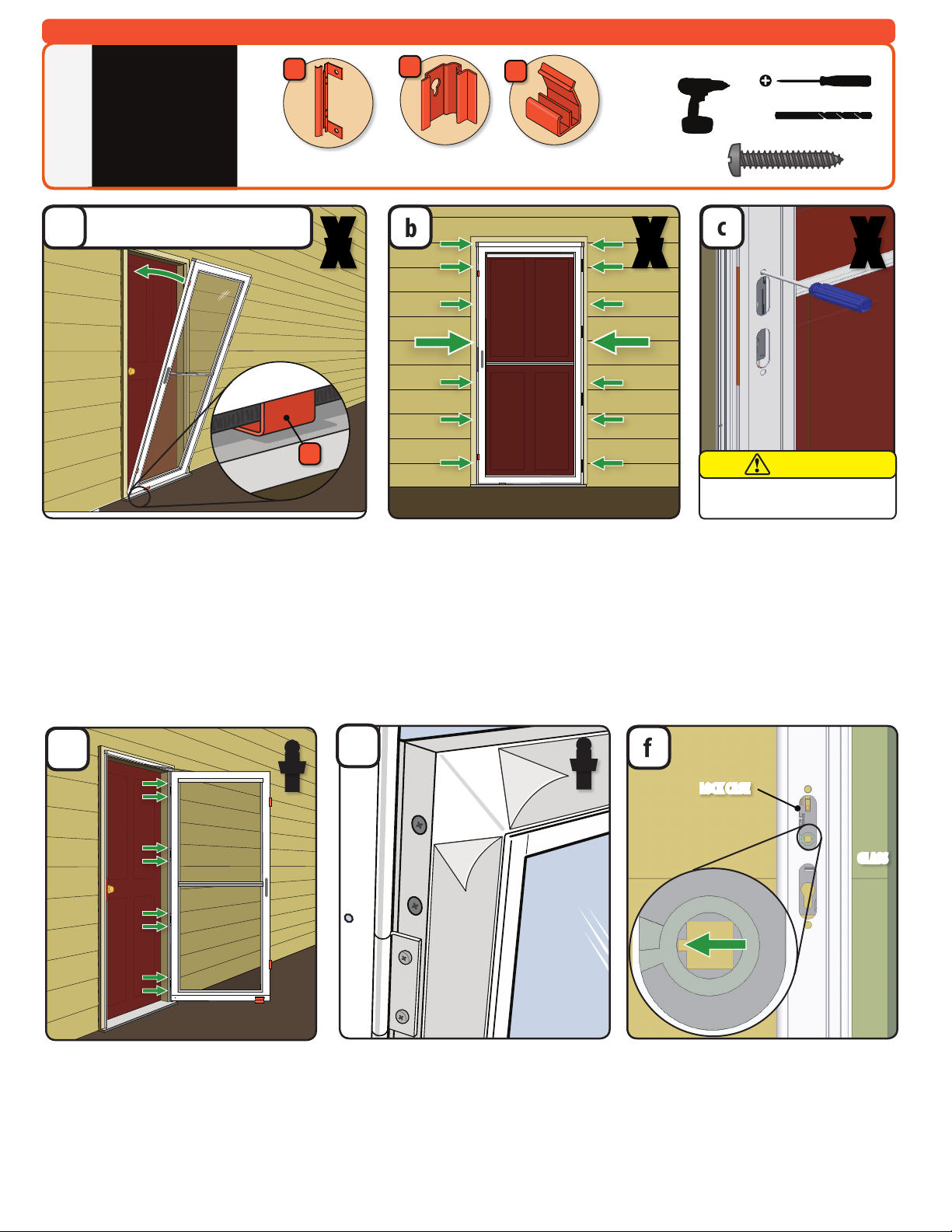

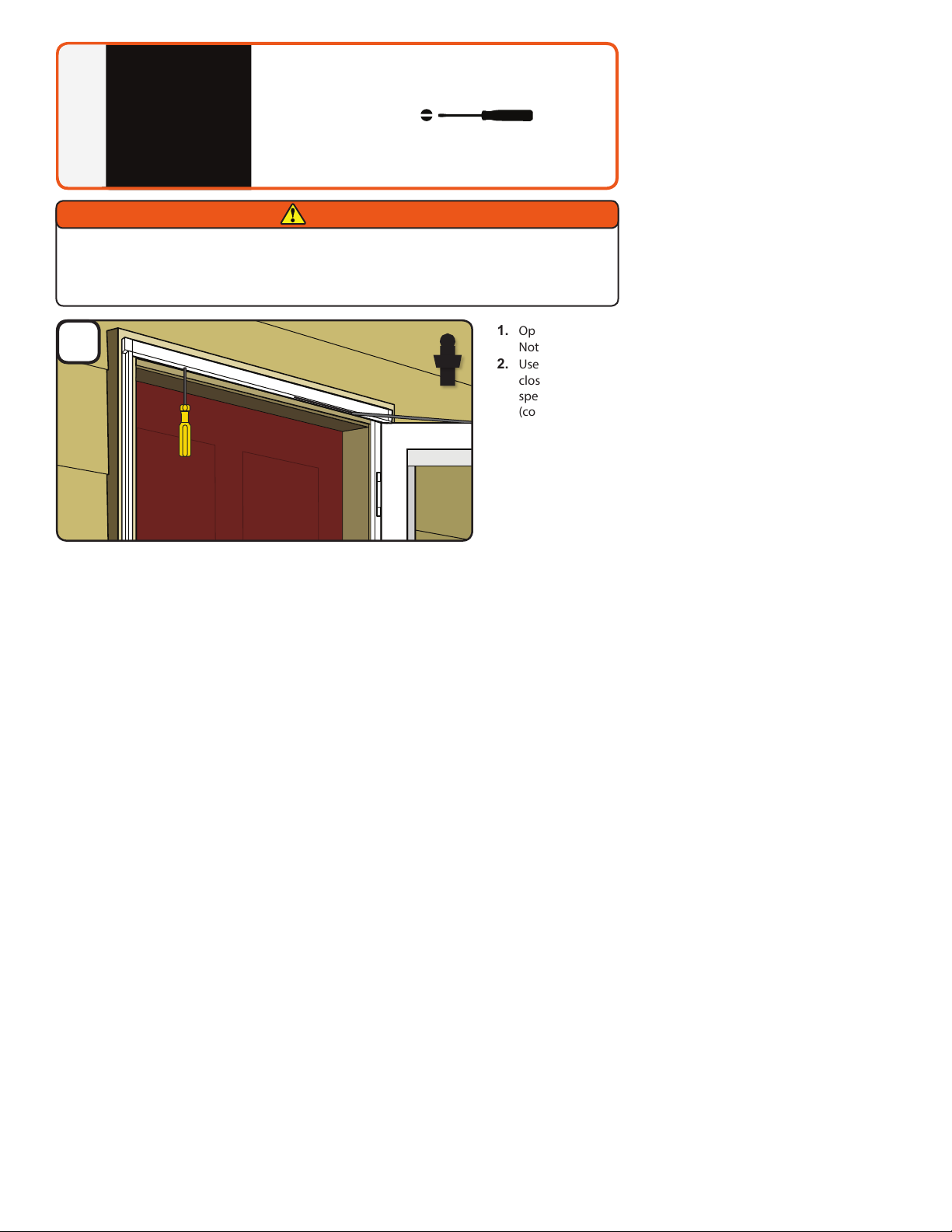

SAFETY FIRST: Please read and follow all Cautions and Warnings in this guide.

RECOMMENDED TOOLS

Drill

Safety Glasses

1/8 Drill Bit

!

!

1/2”

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

!

!

1/2”

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

Work Gloves

Pliers

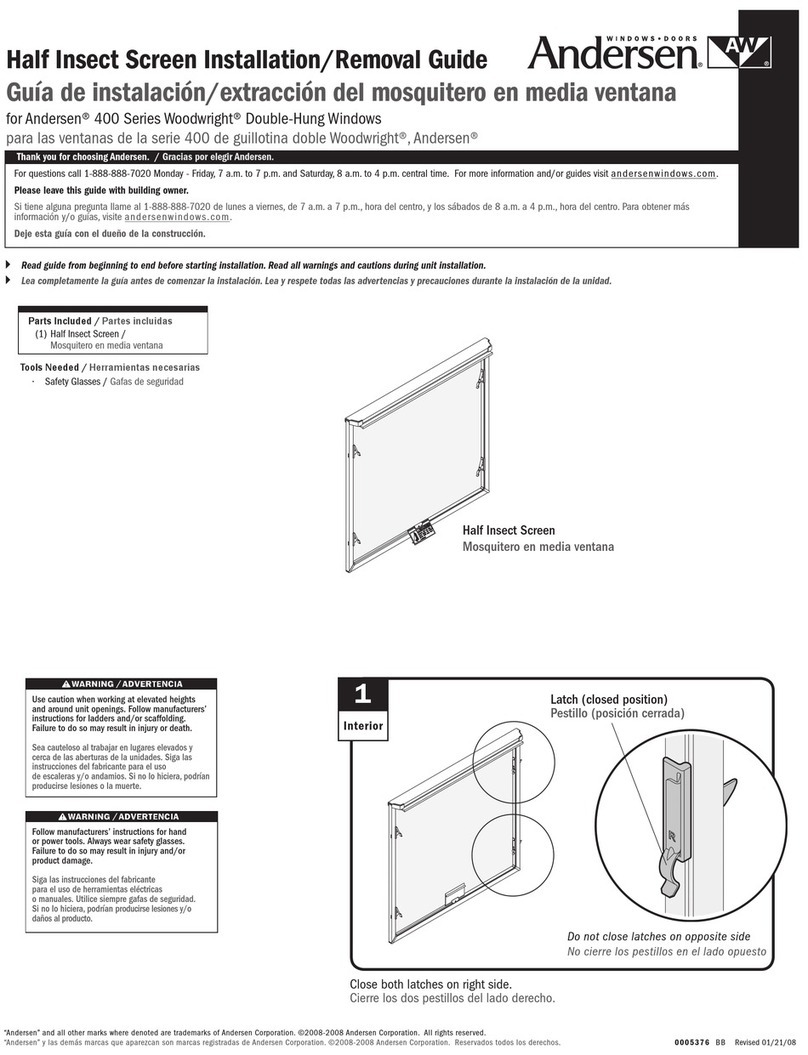

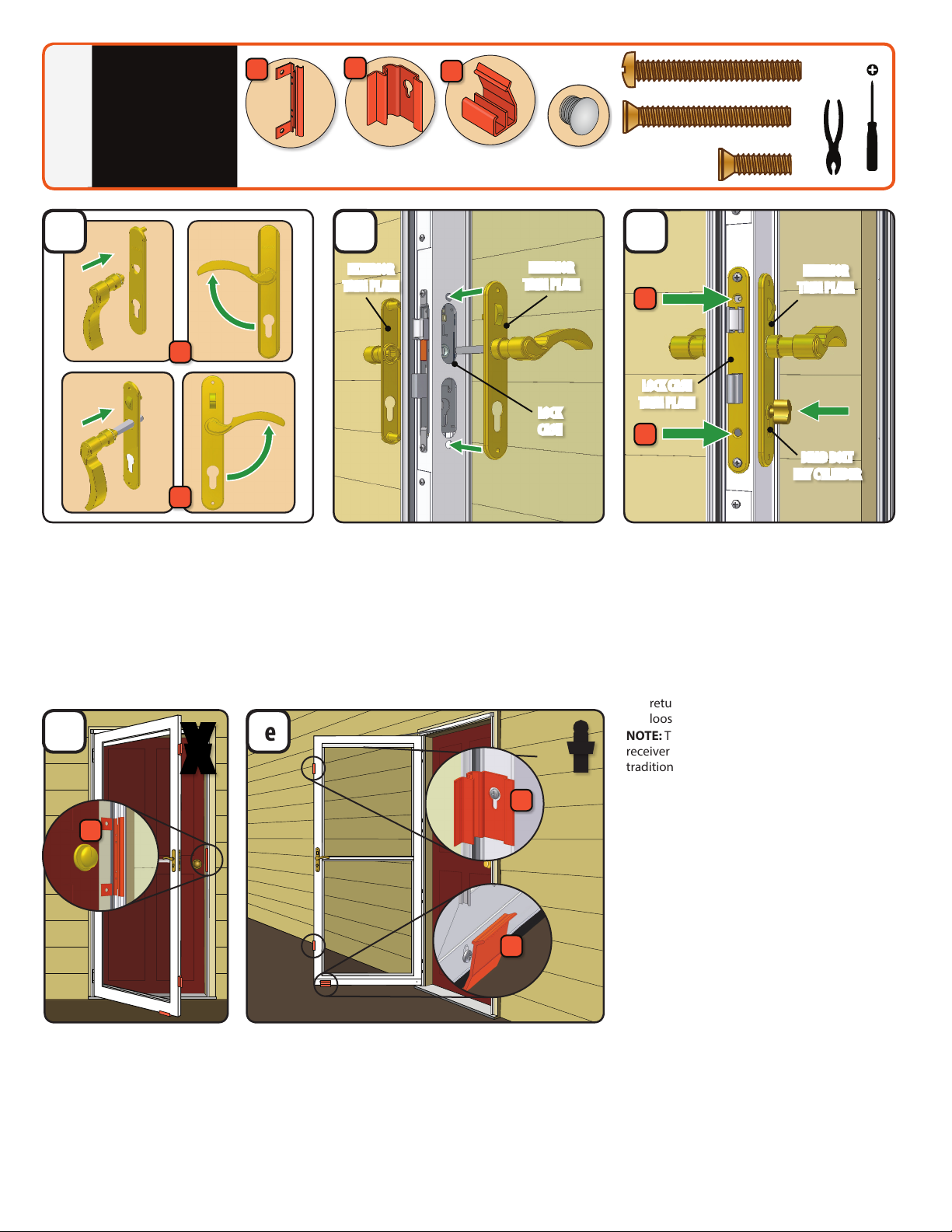

The insect screen is intended for reasonable insect

control and not the retention of objects, persons, or

pets within the interior. The insect screen material

will not stop a person from falling through the door.

Follow manufacturers' instructions for hand and power

tools. Always wear safety glasses. Failure to do so could

result in injury, product or property damage.

Windows and doors can be heavy. Use safe lifting techniques and a reasonable number of people with enough

strength to lift, carry, and install window and door products. Heavier windows and doors will require mechanical

assistance. Failure to do so could result in injury, product or property damage.

Metal fasteners and components could corrode when exposed to preservative-

treated or re-retardent treated lumber. Use approved fasteners and components

to fasten window or door. Failure to do so could cause a failure resulting in injury,

product or property damage.

Fastener must attach to a structural framing member with a 1" minimum fastener

embedment. Failure to do so could result in injury, product or property damage.

DO NOT remove screws that attached installation clips or gusset plates to window

or door frames. Doing so could result in injury, product or property damage.

Storm doors have small

parts. Small parts if

swallowed could pose a

choking hazard to young

children. Dispose of unused,

loose, or easily removed small

parts. Failure to do so could

result in injury.

Metal components of the entry and the storm door

may become hot when exposed to sunlight.

IMPORTANT

WARNING WARNING

WARNING WARNINGCAUTION

Major Injury / Death

Product or Property

Damage

Minor Injury

Procedure and Product

Information

This is the Safety Alert Symbol used to alert you to

potential injury hazards. Obey all safety messages that

follow this symbol to avoid possilbe injury or death.

WARNING

NOTICE

CAUTION

IMPORTANT

Signal Word and Consequence

COULD

Result in:

COULD

Result in:

COULD

Result in:

Tape Measure

!

!

1/2”

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

!

!

1/2”

1/2”

1/2”

1”

1 1/2”

2”

1 1/2”

5/8”

5/8”

Phillips

Screwdriver Straight head

Screwdriver

MEASURE - VERIFY MOUNTING SURFACE REQUIREMENTS AND MEASURE DOOR OPENING*

1