SELF-CLEANING: AUTOMATIC CLEANING;

Your oven is supplied with an automatic self-cleaning system for oven cooking cavity. This self-cleaning system eliminates all cleaning

problems such as internal cleaning manual work and the use of detergents.

Left over soil from food cooking on oven cavity walls are burned out by heat with a temperature between 450 0C and

500 0C for a minimum time of 90 minutes, short cycle. Because of oven high temperature during self-cleaning

operation, the appliance is manufactured using a special isolation material as well as a more powerful cooling fan in

order to preserve internal components and furniture surface conditions.

Oven door is assembled with three tempered glasses, of which internal and middle glasses are Heat Reflecting type of

glass. Forced fresh air is ducted through the door between external and internal glasses to cool down door external

surface temperature.

Oven door automatically locks during self-cleaning cycle because of the high temperature, to prevent burns caused by

accidental door opening. Also, electrical power to appliance is automatically cut-off in case of oven malfunction for

safety. Self-cleaning operation produces fumes and bad odours, but are eliminated through a catalysed unit within the

appliance. After self-cleaning soil may leave a light grey, powder ash which can be removed with a damp sponge at the

end of the cycle and with a cool oven.

Before activating the automatic self-cleaning system, consider the following precautions:

- Oven cooking cavity must be empty of any accessory such as tray and racks.

- Remove heavy soil.

- Check for oven door lock

- Make sure thermostat knob is in the “zero” position.

- In case there is a cooktop above the oven, all gas burners must be off during self-cleaning operation.

On first self-cleaning operation, bad odours are possible caused by burning tool lubricants. This problem will disappear

gradually after a few self-cleaning cycles.

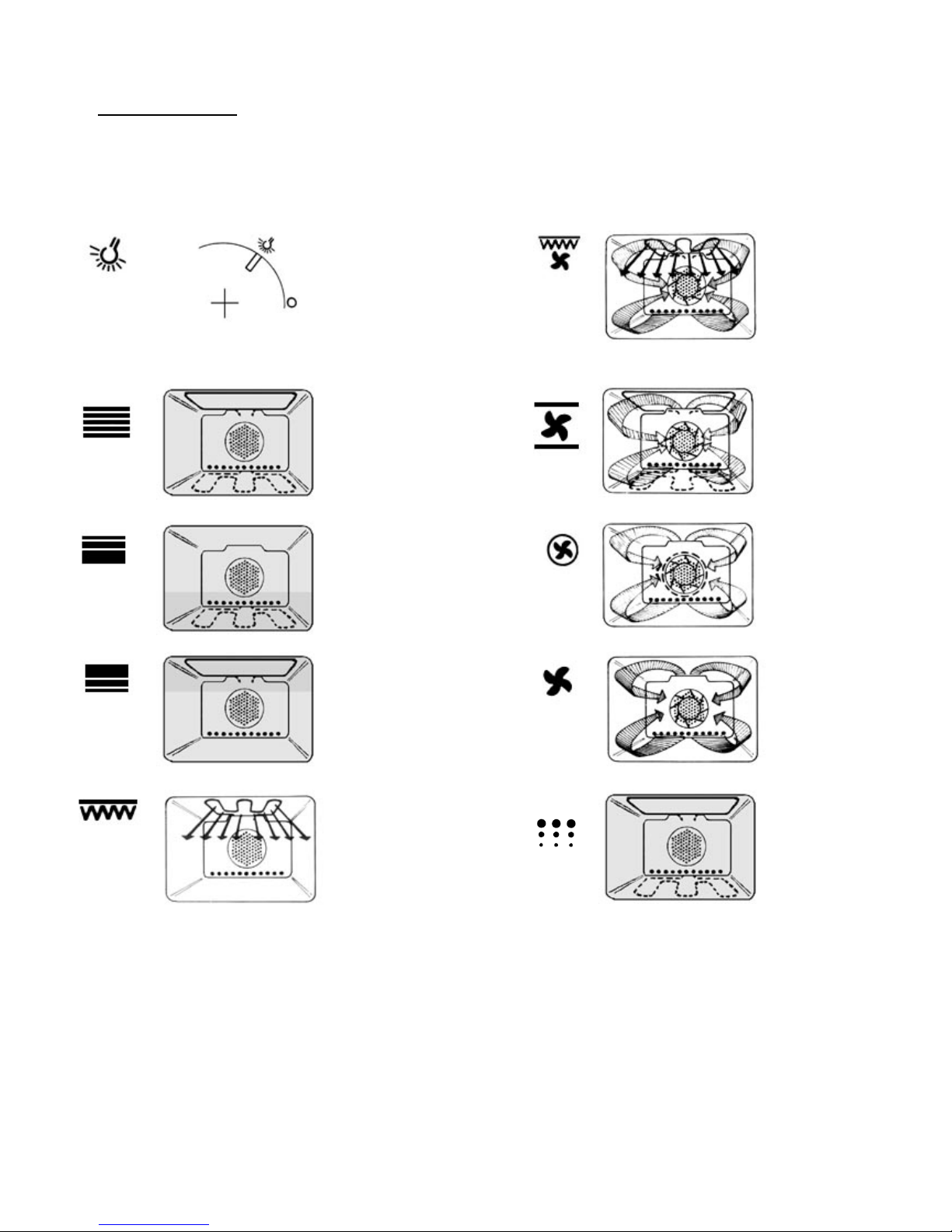

SELF-CLEANING CYCLE MODE: Position selector switch knob on self-cleaning symbol .

Self-cleaning cycle starts automatically with a minimum period of 90 minutes, in case of increasing self-cleaning cycle

time because of heavy soil, press push button with Csymbol together with push button with + symbol; on electronic

programmer. The maximum self-cleaning cycle time that can be selected is 120 minutes.

CAUTION: The appliance is manufactured with a safety device that locks the oven door when inside temperature

reaches 300 0C; once the safety device locks the door an indicator light with symbol will go on. The oven door

will be unlocked once inside temperature has decrease under 300 0C at the end of self-cleaning cycle.

Door lock indicator light will go off as soon as the safety device unlocks oven door. At the end of self-cleaning

cycle, cooling fan will keep on working till oven will cool down even though knob is placed in the “zero”.

Caution: During self-cleaning cycle, access oven components and surface may become very hot; therefore, keep

children at a safe distance. At the end of self-cleaning cycle and when the oven has cooled down completely, wipe the

inside with a damp cloth to remove left over powder.

RACK PLACEMENT FOR SPECIFIC FOODS:

1) Frozen pies, large roast, turkey, angel food cakes, thick well-done meat cuts; rack position is 1st or 2nd rack guide

from the bottom.

2) Bundt cake, most quick breads, yeast breads, casseroles, meats, thick meat cuts; rack position is 2nd rack guide from

bottom.

3) Cookies, biscuits, muffins, cakes, non-frozen pies, thin meat cuts; rack position is 2nd and 3rd rack guide from

bottom.

For Grilling food, rack position is 4th rack guide from bottom or place food 7.5 cm or more from the broil element.

8