6

Version 1.2 rev 11 Jun 2019

SAFETY AND WARNING INFORMATION

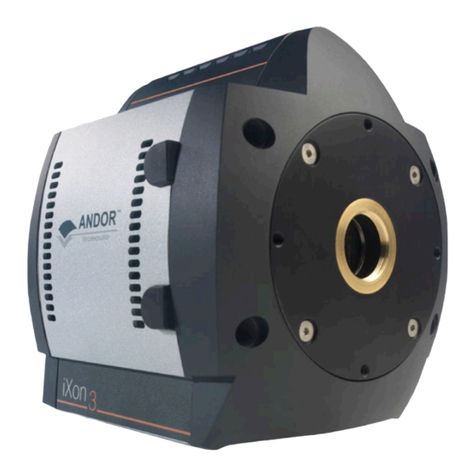

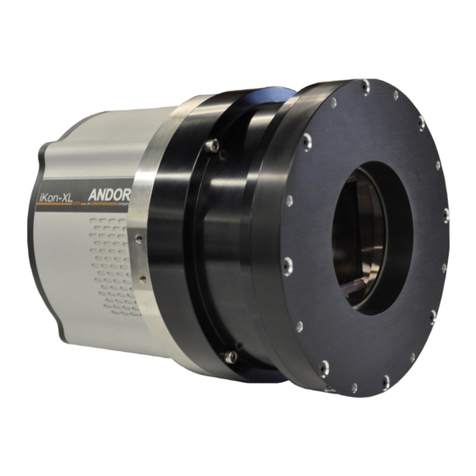

PLEASE READ THIS INFORMATION FIRST BEFORE USING YOUR iSTAR INTENSIFIED sCMOS CAMERA.

1. To ensure correct and safe operation of this product, please read this guide before use and keep it in a safe place for future

reference

2. If equipment is used in a manner not specied by Andor, the protection provided by the equipment may be impaired

3. Before using the system, please follow and adhere to all warnings, safety, manual handling and operating instructions located

either on the product or in this manual

4. An integral part of protection against electric shock in the case of a fault is the protective earth provided via the earth conductors

in the mains cable. It is therefore vital that the earth system of the building, and in particular the socket, is constructed properly

to provide suitable protection when needed.

5. As the main protective earth is also provided via the Andor-supplied External Power Supply, then if this is not used, the

alternative Earth Stud must be used instead (see page 20).

6. The Andor iStar sCMOS is a precision scientic instrument containing fragile components. Always handle with care

7. Do not expose the product to extreme hot or cold temperatures

8. Ensure that a minimum clearance of approximately 100mm (4”) is maintained in front of all ventilation slots and the fan inlet

9. If using water cooling, ensure that cooling water supply is connected prior to powering the camera.

10. Do not expose the product to open ames

11. Do not allow objects to fall on the product

12. Do not expose the product to moisture, wet or spill liquids on the product. Do not store or place liquids on the product. If a

spillage occurs on the product, switch off power immediately, and wipe off with dry, lint-free cloth. If any ingress has occurred or

is suspected, unplug the mains cable, do not use, and contact Andor service

13. The product contains components that are extremely sensitive to static electricity and radiated electromagnetic elds, and

therefore should not be used, or stored, close to EMI/RFI generators, electrostatic eld generators, electromagnetic or

radioactive devices, or other similar sources of high energy elds

14. Operation of the system close to intense pulsed sources (e.g. plasma sources, arc welders, radio frequency generators, X-ray

instruments, and pulsed discharge optical sources) may compromise performance if shielding of the iStar sCMOS is inadequate

15. This product is not designed to provide protection from ionising radiation. Any customer using this product in such an

application should provide their own protection

16. The Andor iStar sCMOS is for use in research laboratories and other controlled scientic environments

17. This equipment has not been designed and manufactured for the medical diagnosis of patients

18. Use only the power supply cord provided with the system for this unit. Should this not be correct for your geographical area

contact your local Andor representative

19. Only the correctly specied mains supply and fuse must be used

20. Make sure the electrical cord is located so that it will not be subject to damage

22. There are no user-serviceable parts beyond the specied user accessible areas of the product and the enclosure must not be

opened. Only authorised service personnel may service this equipment

23. The above label indicates that this unit contains components which are sensitive to and can be damaged by electrostatic

discharge. When working on a unit which is not enclosed, it is necessary to follow anti static precautions to ensure damage does

not occur.

RegulatoRy ComplianCe

The iStar sCMOS complies with the requirements of the EU EMC and LV Directives

through testing to EN 61326-1 and EN 61010-1.

This product requires a DC power supply (refer to Section 1.6)