Page 7

Introduction

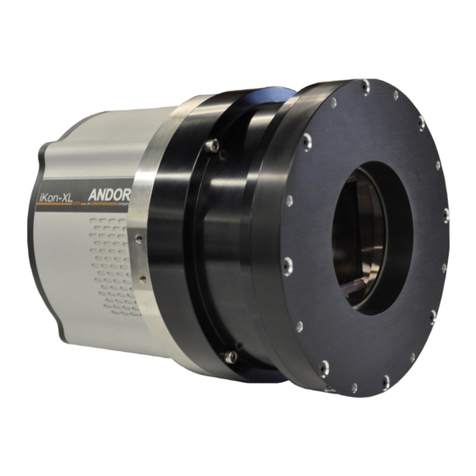

SECTION 1 - INTRODUCTION TO iXon3 HARDWARE

Thank you for choosing the Andor iXon3. You are now in possession of a revolutionary new Electron Multiplying Charge

Coupled Device (EMCCD), designed for the most challenging low-light imaging applications. This manual contains useful

information and advice to ensure you get the optimum performance from your new system. If you have any questions

regarding your iXon3 system, please feel free to contact Andor directly, or via your local representative or supplier. You

can nd contact details below.

1.1 - TECHNICAL SUPPORT

If you have any questions regarding the use of this equipment, please contact the representative* from whom your

system was purchased, or:

Europe

Andor Technology plc

7 Millennium Way

Springvale Business Park

Belfast

BT12 7AL

Northern Ireland

Tel. +44 (0) 28 9023 7126

Fax. +44 (0) 28 9031 0792

www.andor.com/contact_us/support_request

Asia-Pacic

Andor Technology (Japan)

4F NE Sarugakucho Building

2-7-6 Sarugaku-Cho

Chiyoda-Ku

Tokyo 101-0064

Japan

Tel. +81-3-3518 6488

Fax. +81-3-3518 6489

www.andor.com/contact_us/support_request

USA

Andor Technology

425 Sullivan Avenue

Suite # 3

South Windsor

CT 06074

USA

Tel. (860) 290-9211

Fax. (860) 290-9566

www.andor.com/contact_us/support_request

China

Andor Technology

Room 1213, Building B

Luo Ke Time Square

No. 103 Huizhongli

Chaoyang District

Beijing,100101 P.R.

China

Tel: +86 (0)10 51294977

Fax. +86 (0)10-6445-5401

www.andor.com/contact_us/support_request

The latest contact details for your local representative can be found on our website via the following link:

http://www.andor.com/contact_us/Default.aspx