5

NT_ANEP_BOX_TX+_EN_04-07-2023

9.3 - BOX TX+ clock setting Page 37

9.3.2 - Local time display

9.4 - Floor statement

9.4.1 - Statement validation Page 38

9.4.2 - Devalidation of statements

9.4.3 - Level programming via keypad

Modification of floor announcements Page 39

9.4.4 - Broadcasting between 8 a.m. and 8 p.m. Page 40

9.4.5 - Indication de la période d’annonce des étages

10 - SERVICE VOICE / ALARM ACKNOWLEDGEMENT Page 40

10.1 - Validation of «Alarm in Progress» & «Technician Arrival» announcements

10.2 - Disabling of «Alarm in progress» & «Technician arrival» announcements

10.3 - Cabin alarm acknowledgement

11 - SPEAKER AND MICROPHONE TEST Page 41

11.1 - Periodic call test

11.2 - Test on request operator

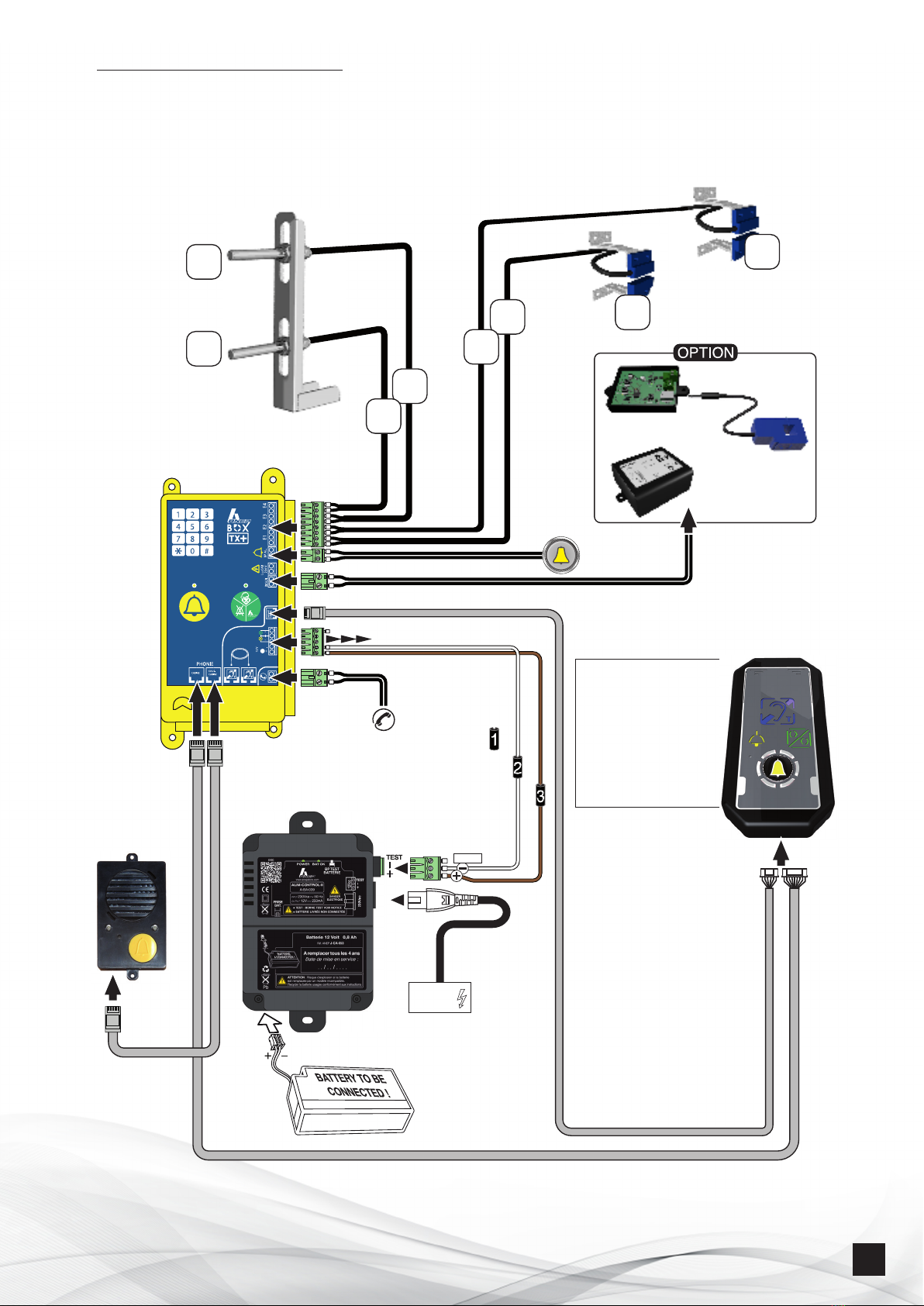

12 - PRESENTATION OF THE TX+ VERSION Page 42

12.1 - Elevator monitoring Page 43

12.1.1 - Validation of elevator monitoring mode

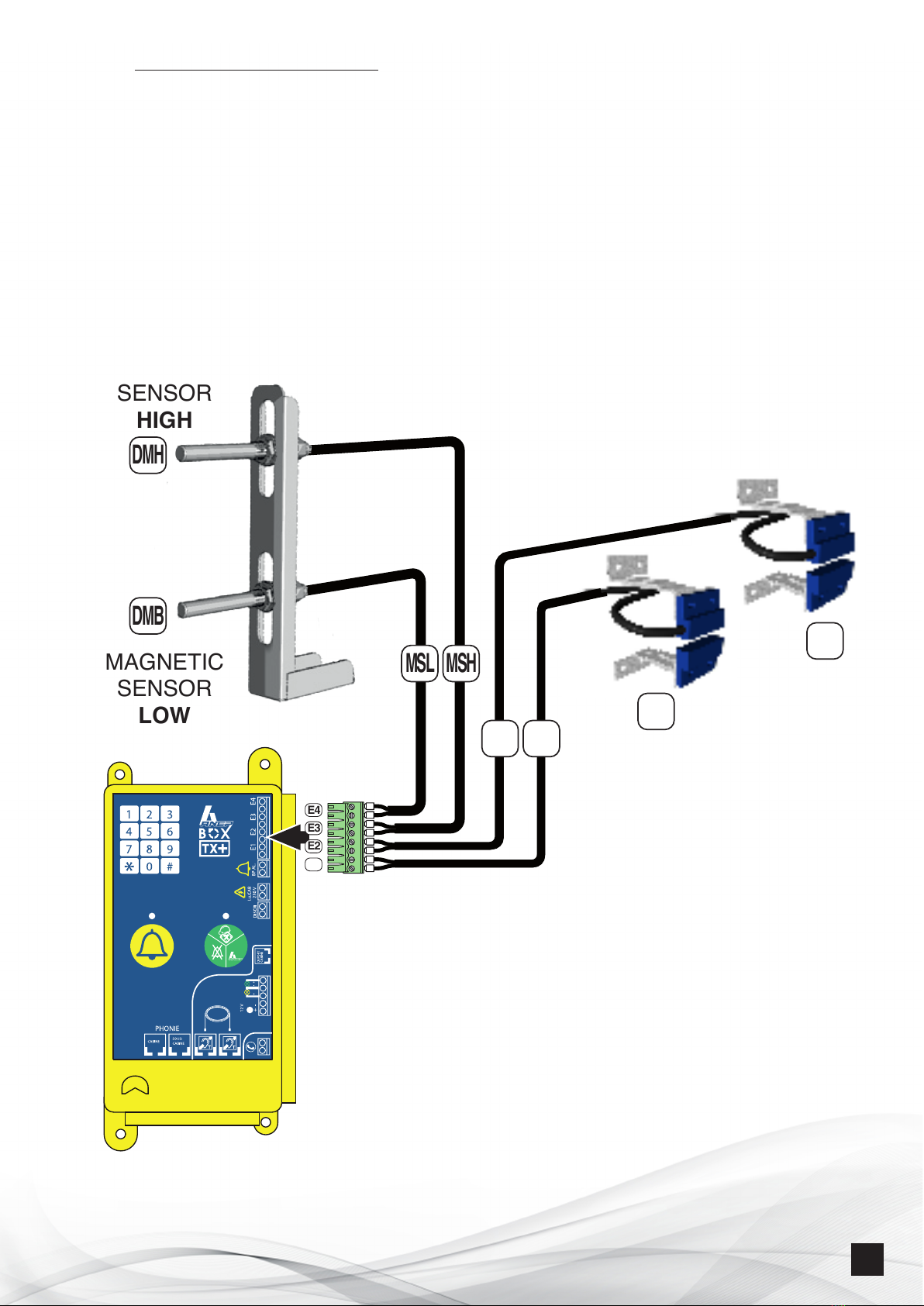

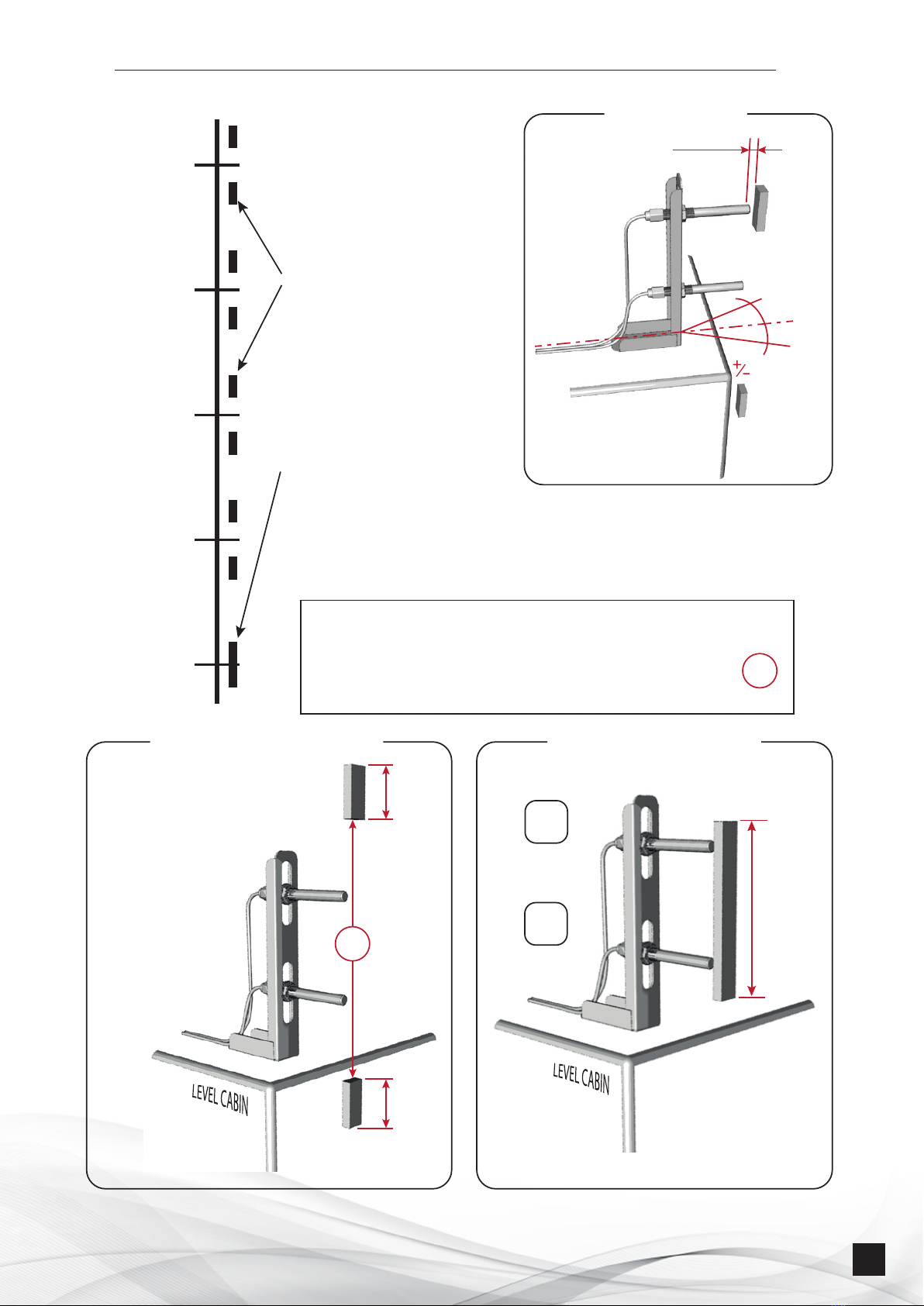

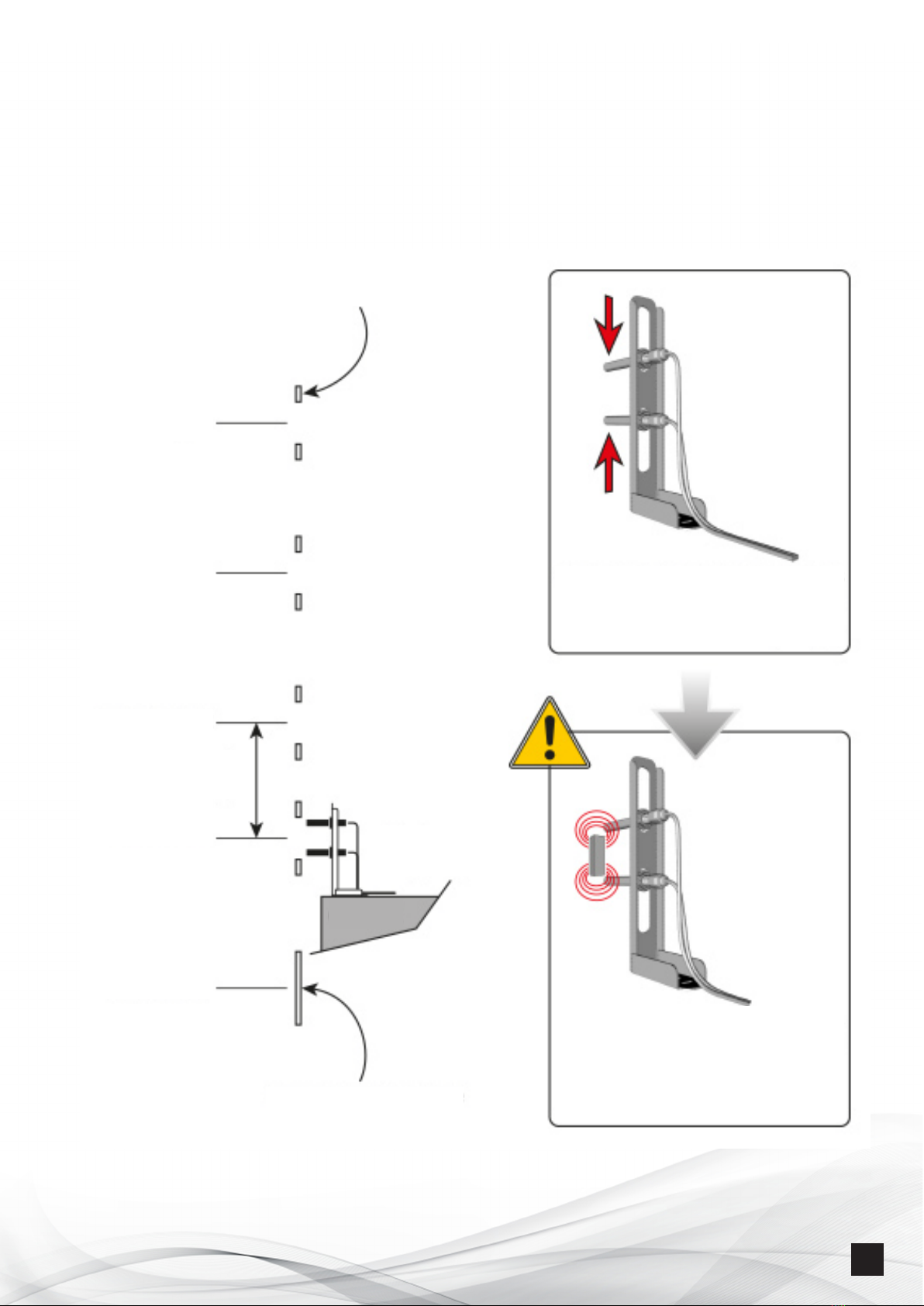

12.1.2 - Learning procedure

12.1.3 - Sheath learning launch Page 44

12.2 - Event validation (Faults/Malfunctions)

12.2.1 - Event validation sequence

Sheath learning diagram Page 45

12.2.2 - Fault inhibition sequence Page 46

12.2.3 - Event references

12.2.4 – Reading fault validation Page 47

12.2.5 – Door type reading

12.2.6 – Programming inactivity time

12.2.7 – Technical fault ltering Page 48

12.3 - Commissioning checks Page 49

12.3.1 - Door information control

12.3.2 - Monitoring control

12.3.2.1 - Check surveillance mode validation

12.3.2.2 - Check synthesizer operation

12.3.2.3 - Checking failure transfer

13 - KEYBOARD PROGRAMMING TABLE Page 50

KEYBOARD PROGRAMMING TABLE (CONTINUED) Page 51

14 - KEYBOARD PROGRAMMING TABLE WITH BOX-INTENS Page 52

NOTES AND WARRANTY Page 53