2Article-no.: 13424999549 Date: 04.11.2016 Version: 1.7

Content

1..........General ......................................................................................................................... 5

2..........Safety............................................................................................................................ 5

2.1.......Intended use ...............................................................................................................................................5

2.2.......Explanation of symbols...............................................................................................................................5

2.3.......Fundamental safety regulations..................................................................................................................6

2.3.1....Electrical safety...........................................................................................................................................6

2.4.......Responsibilities and quality requirements ..................................................................................................6

2.4.1....Duties of the Operator ................................................................................................................................6

2.4.2....Obligation to undertake maintenance work and service.............................................................................7

2.4.3....Further information concerning maintenance .............................................................................................7

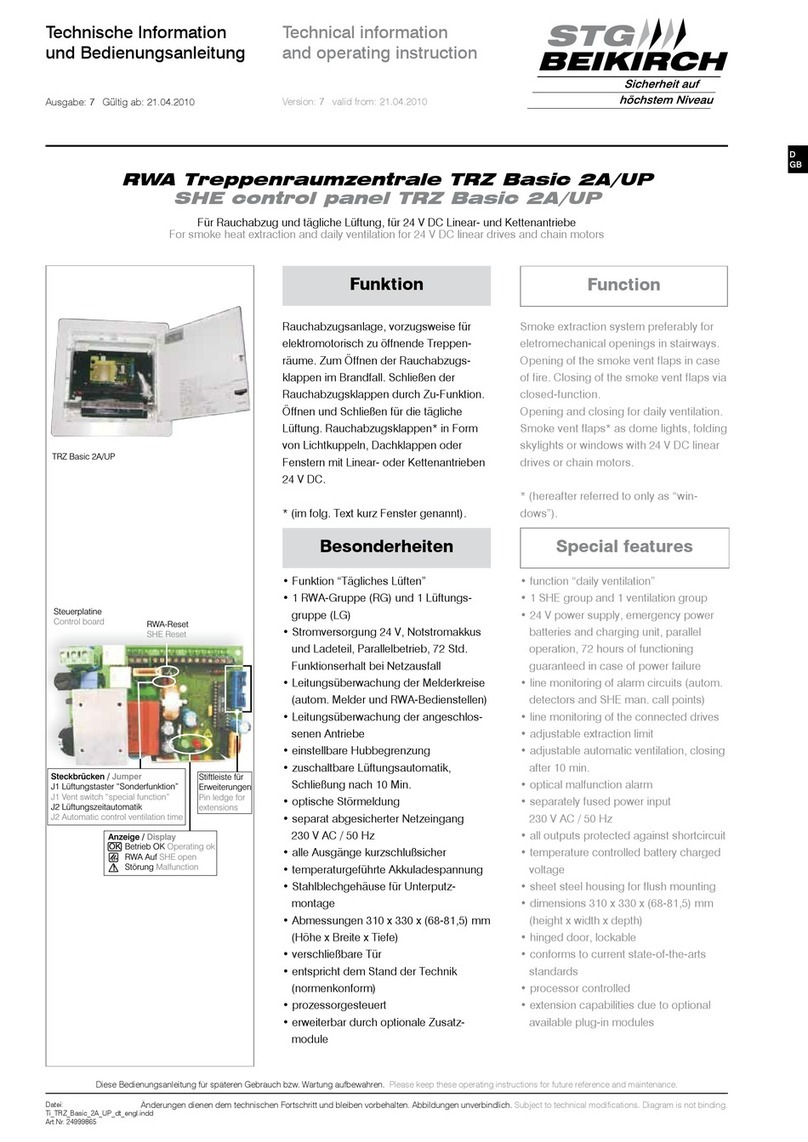

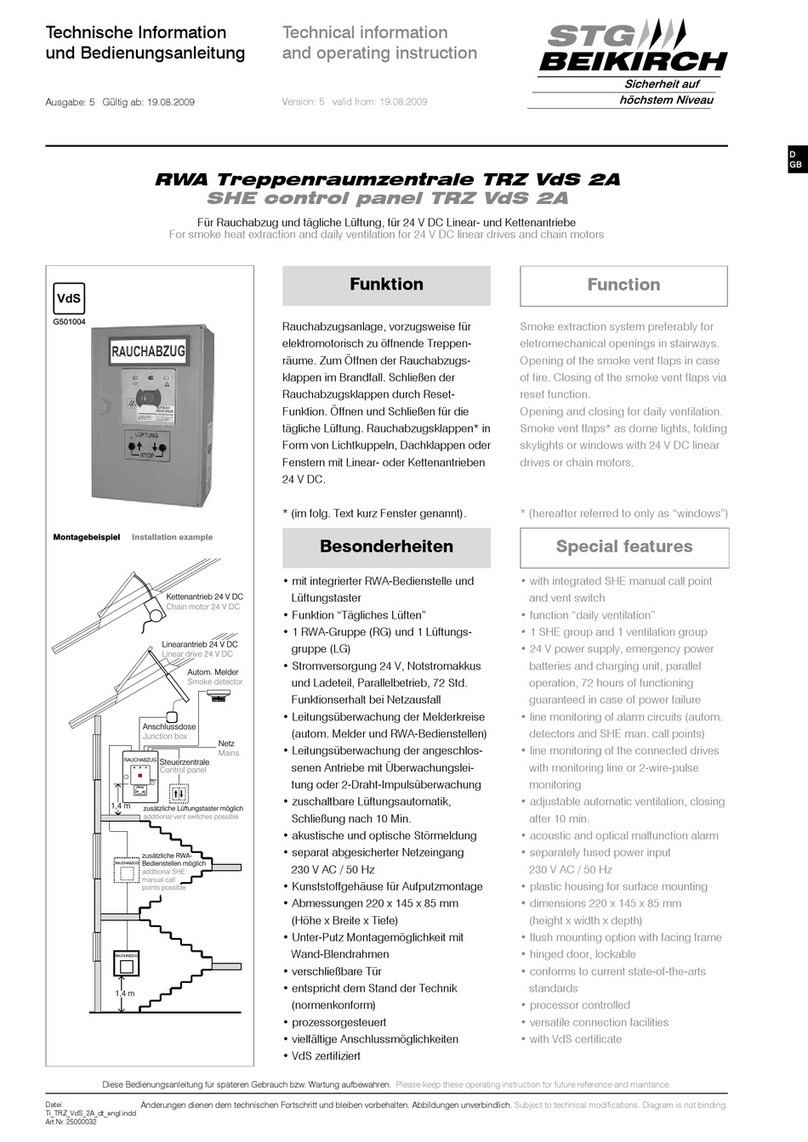

3..........Product description........................................................................................................ 8

4..........Technical specifications ................................................................................................ 9

4.1.......Switch cabinet dimensions .........................................................................................................................9

4.2.......Weights .......................................................................................................................................................9

4.3.......Electrical connection...................................................................................................................................9

4.4.......Accumulators ............................................................................................................................................10

4.5.......Manual call points output ..........................................................................................................................10

4.6.......Automatic detector output.........................................................................................................................10

4.7.......Wind/rain detector output..........................................................................................................................10

4.8.......Requirements on the installation site........................................................................................................11

4.9.......Approvals and certificates.........................................................................................................................11

4.9.1....Declaration of performance (EEC Construction Products Regulation, German BauPVO) ......................11

5..........Packaging, transport and storage ............................................................................... 12

5.1.......Disposing of the packaging.......................................................................................................................12

5.2.......Safety instructions for transport................................................................................................................12

5.2.1....Symbols on the packaging........................................................................................................................12

5.3.......Intermediate storage (short-term storage)................................................................................................12

6..........Installation ................................................................................................................... 13

6.1.......Installing the switch cabinet ......................................................................................................................13

6.2.......Electrical connection.................................................................................................................................14

6.3.......Electrical connection of components outside the building........................................................................14

6.4.......Sample cabling diagram ...........................................................................................................................15

6.5.......Cable cross-section calculation ................................................................................................................16

6.6.......Cable length diagram................................................................................................................................16

6.7.......Cable cross-section table .........................................................................................................................17

6.8.......Connection of actuators to the motor module (MM) .................................................................................17

6.9.......Connection to the ventilation module (LM) ...............................................................................................18

6.10.....Connection to the SHE module (RM) .......................................................................................................21

6.11.....Connection to the IOM module (IOM).......................................................................................................23

6.12.....Connection to the installation bus (EiB*) – Konnex (KNX*) module.........................................................23

7..........Commissioning............................................................................................................ 24

7.1.......Preparatory measures ..............................................................................................................................24

7.2.......Installing the accumulators .......................................................................................................................24

7.3.......Functional test and test run ......................................................................................................................26

7.3.1....Functional test of the vent switch..............................................................................................................26

7.3.2....Functional test of ventilation key-operated push button ...........................................................................26

7.3.3....Functional test of the SHE* manual call point ..........................................................................................27

7.3.4....Functional test of the automatic detector..................................................................................................28