Subject to technical alteration

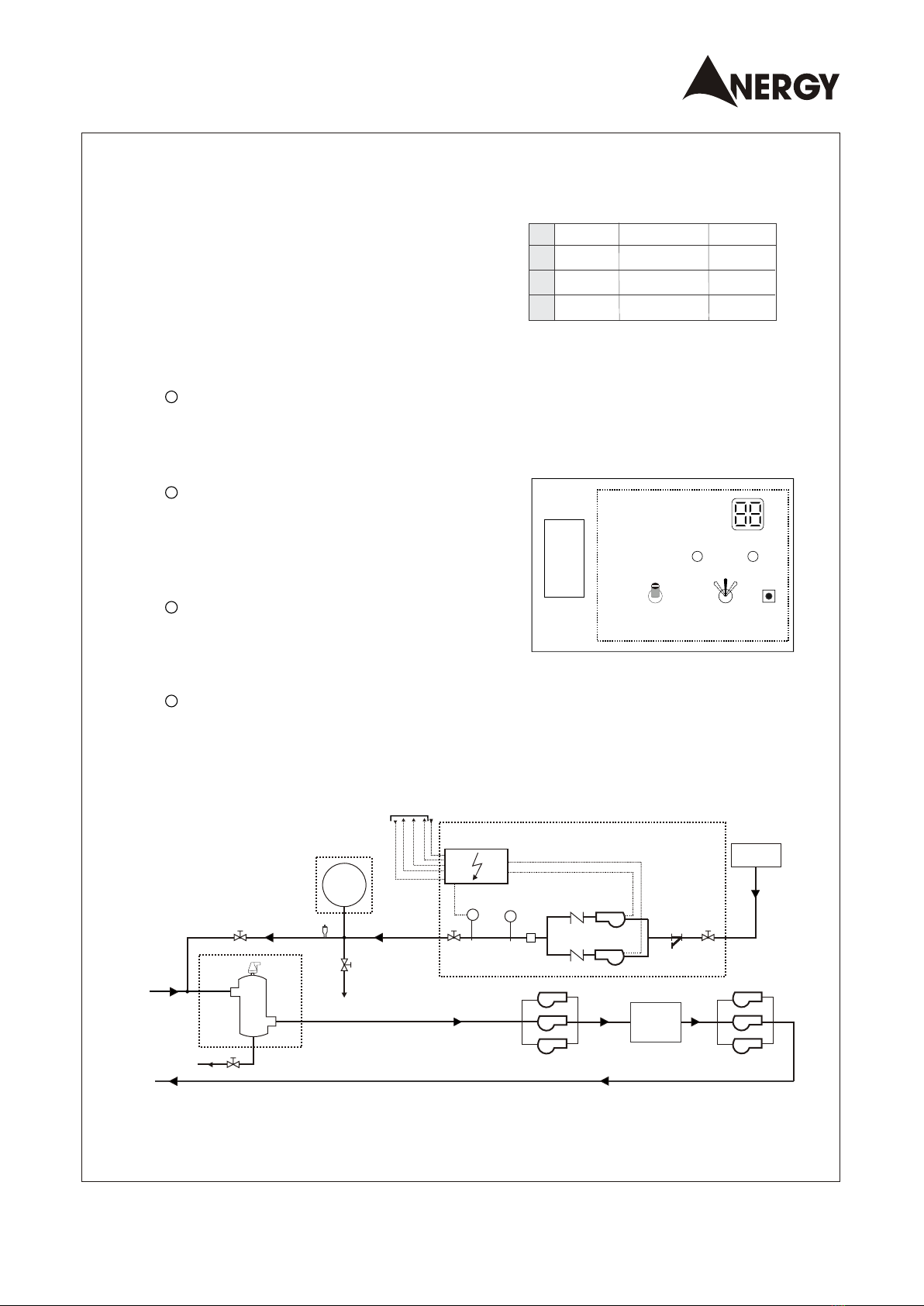

Fig.1 Control Panel

1

2

3

4

0819

M.C.B. Pump 1 Pump 2

LED LED

Pr. Display

Auto

Toggle Switch

All dimensions are in mm

PSU-225 PSU-225 - 2100 PSU-2150

L

W

H

INSTALLATION AND

COMMISSIONING

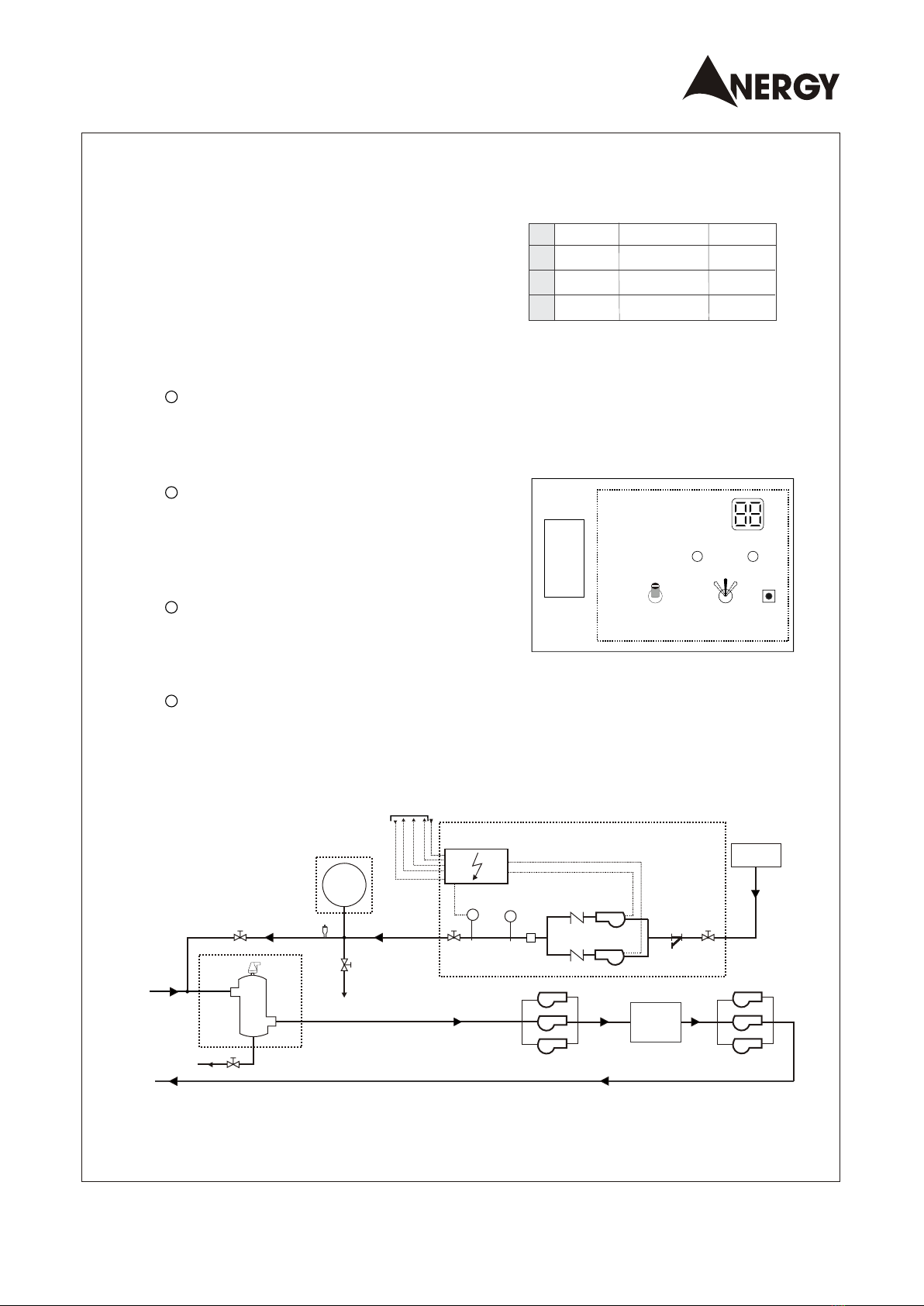

Fig.2 Schematic drawing of pressurisation unit, expansion tank and air separator.

Make-up

Water Tank

Expansion Tank

Pressurisation Unit

Air Separator

From AHU’S

To AHU’S

Drain Valve

Isolation Valve

To Drain

Drain Valve

Make-up

Pump

NRV

Chillers

Primary Pumps Secondary Pumps

NRV

Make-up

Pump

230V AC

1 Ph

(by others)

(by others)

(by others)

Control Panel

Transmitter

BMS

Pressure

Remote On/Off

Alarm

Pump Status

Safety

Valve

0

0

Flow

Meter

Pr.

Set Point - The Set point of the pressure

is set by turning the pressure setting knob.

On turning the knob, display starts blinking

and shows the set-point. It again shows the

actual pressure when it is left idle for 15secs.

Auto Mode - Pump switches OFF when the

pressure exceeds the set-point and is switched

ON, as the pressure goes below (one bar) the

set-point. If the pressure is not acheived in 15mins,

the pump will switch OFF and after 1min other

pump will start to achieve the required pressure.

Manual Mode - Operation can be switched from

Auto mode to Manual mode for Pump 1/ Pump 2

by the toggle switch. In manual mode, the pump

operates continuously for 30mins, then stops

for 10mins before restarting.

Alarm - A NO contact of relay is provided for the

alarm which closes when an alarm is raised. In

case of alarm, press reset key to clear alarm or

switch OFF & then switch ON the mains.

1. Mount on a PCC foundation.

2. Connect water supply to the inlet

connection.

3. Connect outlet to the expansion tank.

4. Control Panel’s (fig.1) functions

are described below:

DIMENSIONS

Strainer

Pr.

Gauge

(PN10)

500 700 700

500 700 700

520 1050 1050

(PN16) (PN20)

Reset Switch

Pressure Setting Knob

Manual for Manual for

Pump 1 Pump 2

*

*Flow Meter not included with PN20 units.