2

Table Of Contents

1 ABOUT THIS MANUAL.................................................................................................................................. 3

1.1 PURPOSE ...................................................................................................................................................... 3

1.2 SCOPE........................................................................................................................................................... 3

2 SAFETY INSTRUCTIONS .............................................................................................................................. 3

3 INTRODUCTION ............................................................................................................................................. 4

3.1 FEATURES ..................................................................................................................................................... 4

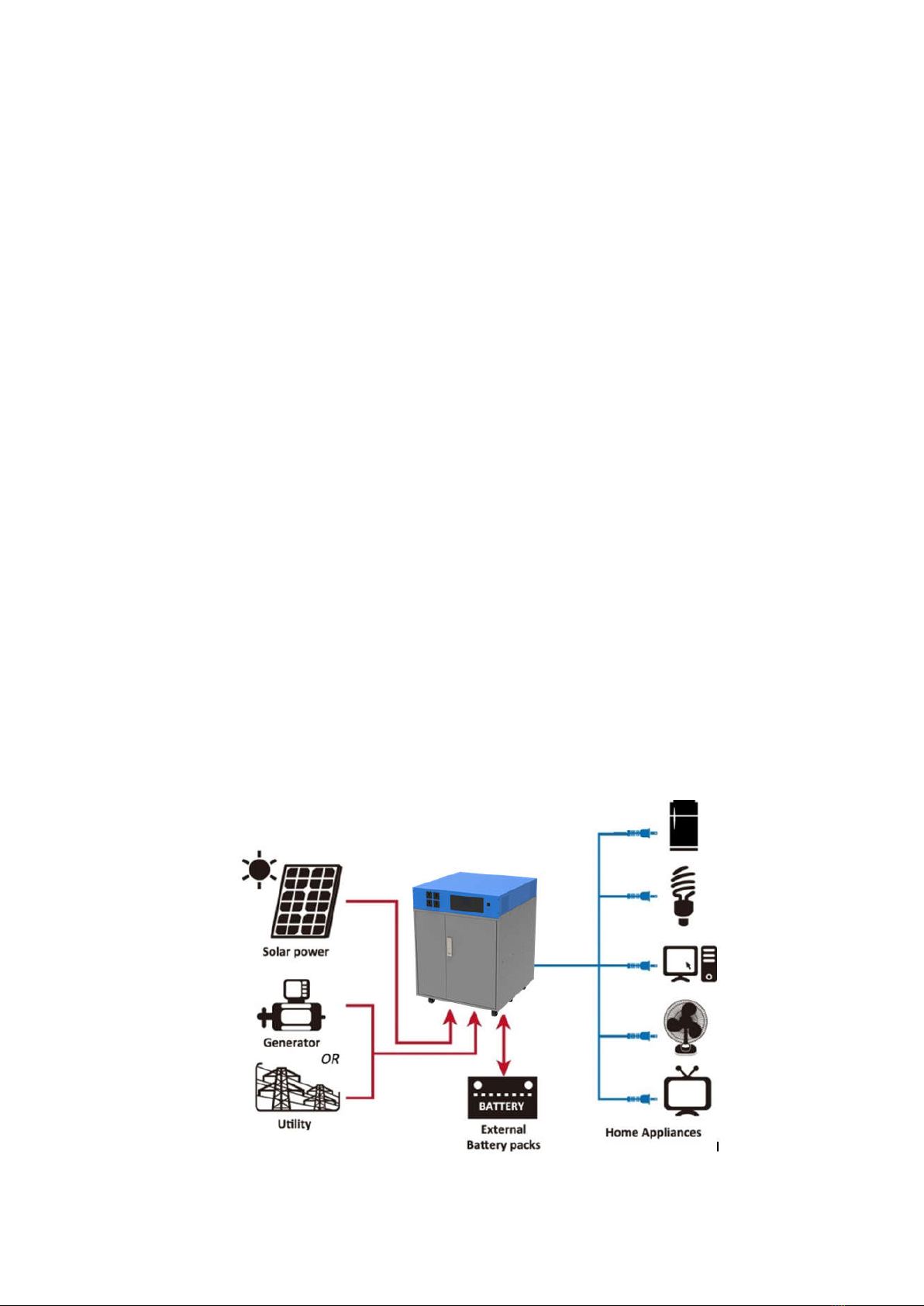

3.2 BASIC SYSTEM ARCHITECTURE ................................................................................................................... 4

3.3 PRODUCT OVERVIEW ................................................................................................................................... 5

4 INSTALLATION ............................................................................................................................................... 7

4.1 UNPACKING AND INSPECTION ...................................................................................................................... 7

4.2 PREPARATION ............................................................................................................................................... 7

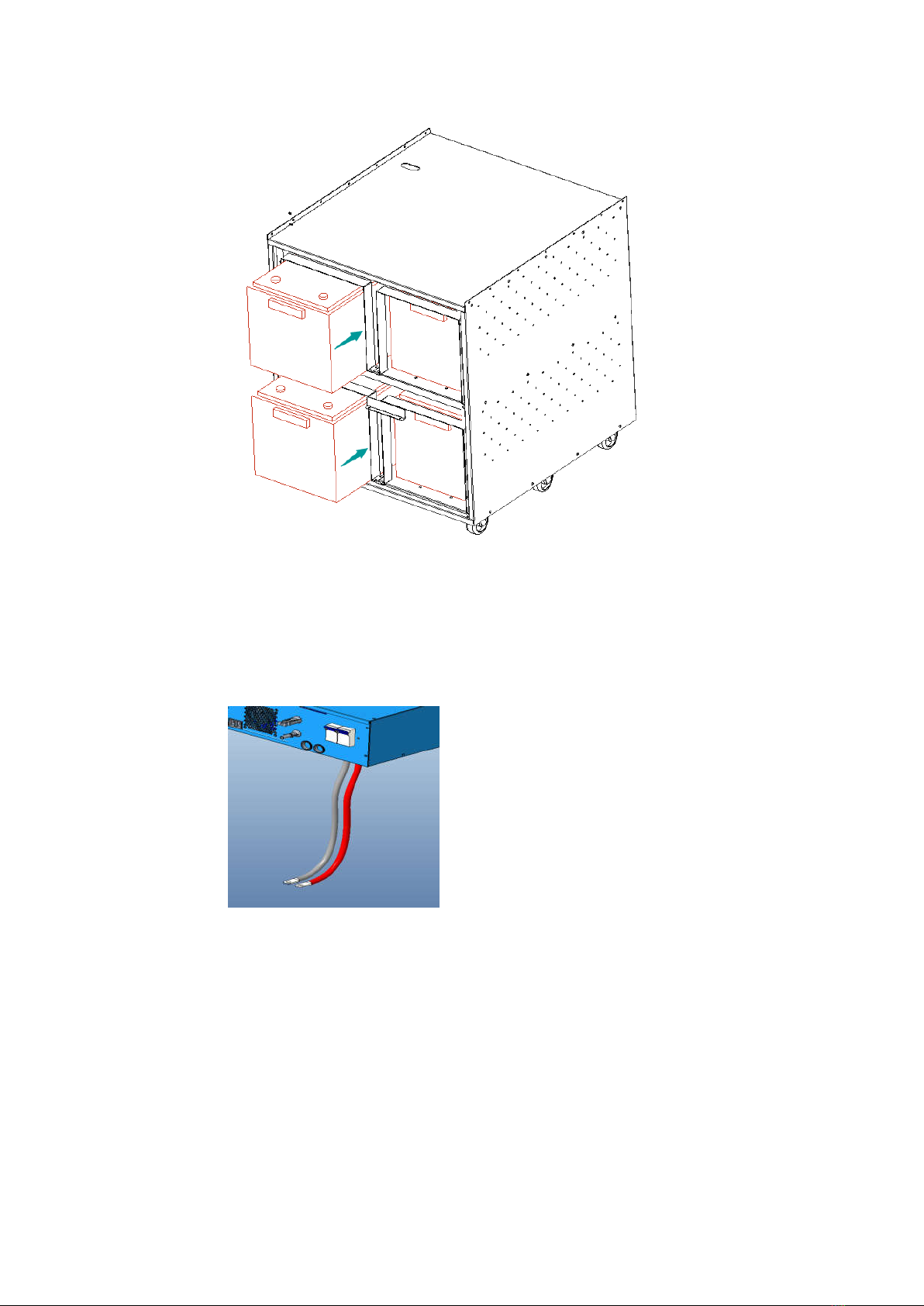

4.3 MOUNTING THE UNIT ................................................................................................................................... 7

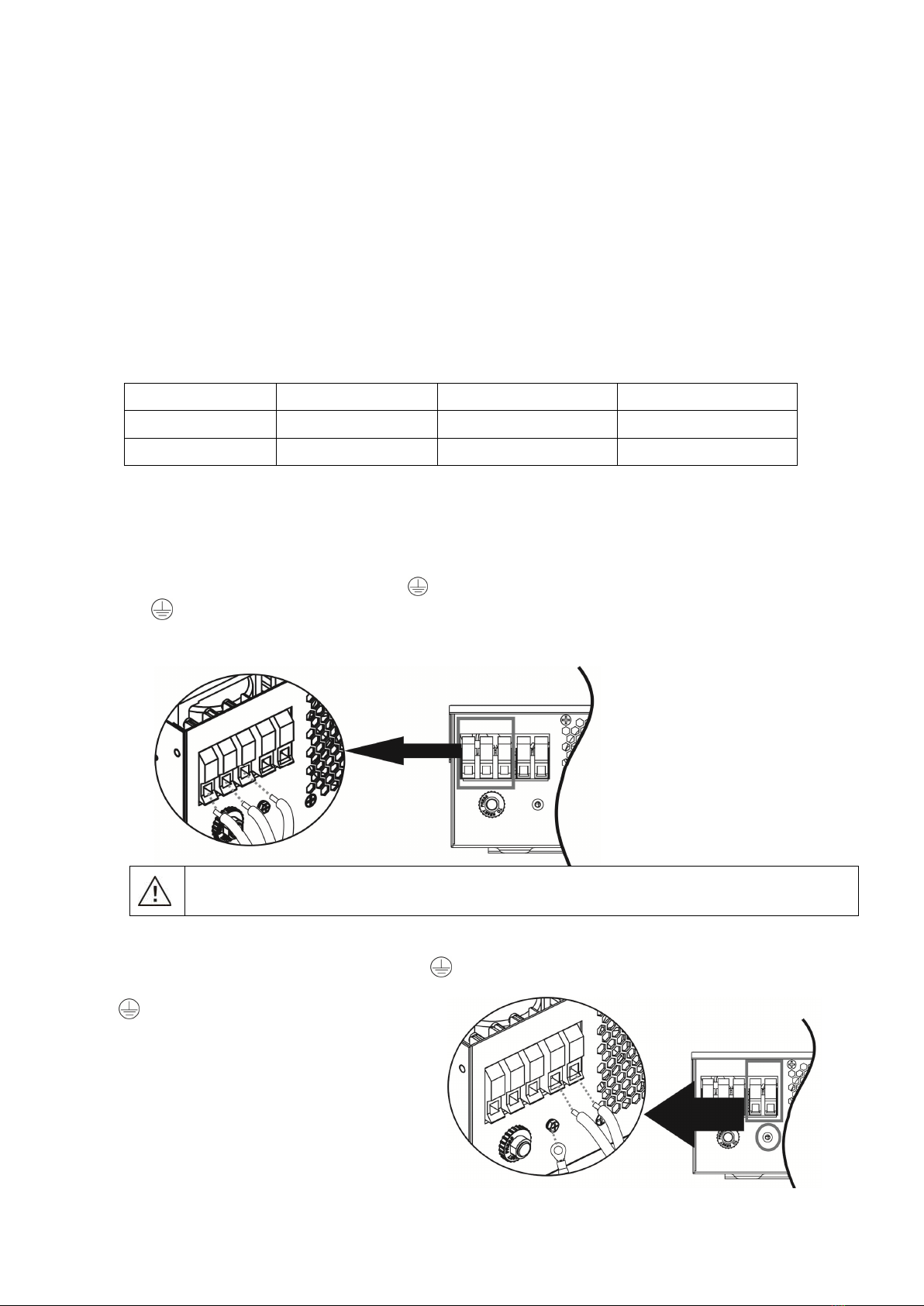

4.4 BATTERY CONNECTION ................................................................................................................................ 8

4.5 AC INPUT/OUTPUT CONNECTION ................................................................................................................ 9

4.6 PV CONNECTION ........................................................................................................................................ 10

4.7 FINAL ASSEMBLY ....................................................................................................................................... 10

4.8 COMMUNICATION CONNECTION................................................................................................................. 12

5 OPERATION ................................................................................................................................................... 13

5.1 POWER ON/OFF ........................................................................................................................................ 13

5.2 OPERATION AND DISPLAY PANEL ............................................................................................................... 13

5.3 LCD DISPLAY ICONS .................................................................................................................................. 15

5.4 LCD SETTING ............................................................................................................................................ 17

5.5 DISPLAY SETTING ....................................................................................................................................... 24

5.6 OPERATING MODE DESCRIPTION ............................................................................................................... 27

5.7 BATTERY EQUALIZATION DESCRIPTION ..................................................................................................... 29

5.8 FAULT REFERENCE CODE ........................................................................................................................... 31

5.9 W

ARNING INDICATOR ................................................................................................................................. 31

6 SPECIFICATIONS ......................................................................................................................................... 32

TABLE 1 LINE MODE SPECIFICATIONS ...................................................................................................................... 32

TABLE 2 INVERTER MODE SPECIFICATIONS .............................................................................................................. 33

TABLE 3 CHARGE MODE SPECIFICATIONS ................................................................................................................. 34

TABLE 4 GENERAL SPECIFICATIONS .......................................................................................................................... 34

7 TROUBLE SHOOTING ................................................................................................................................. 35

8 APPENDIX: APPROXIMATE BACK-UP TIME TABLE .......................................................................... 36