ANETS AS SERIES INSTALLATION & OPERATIONAL MANUAL

8 150-000002 Rev A (2/19)

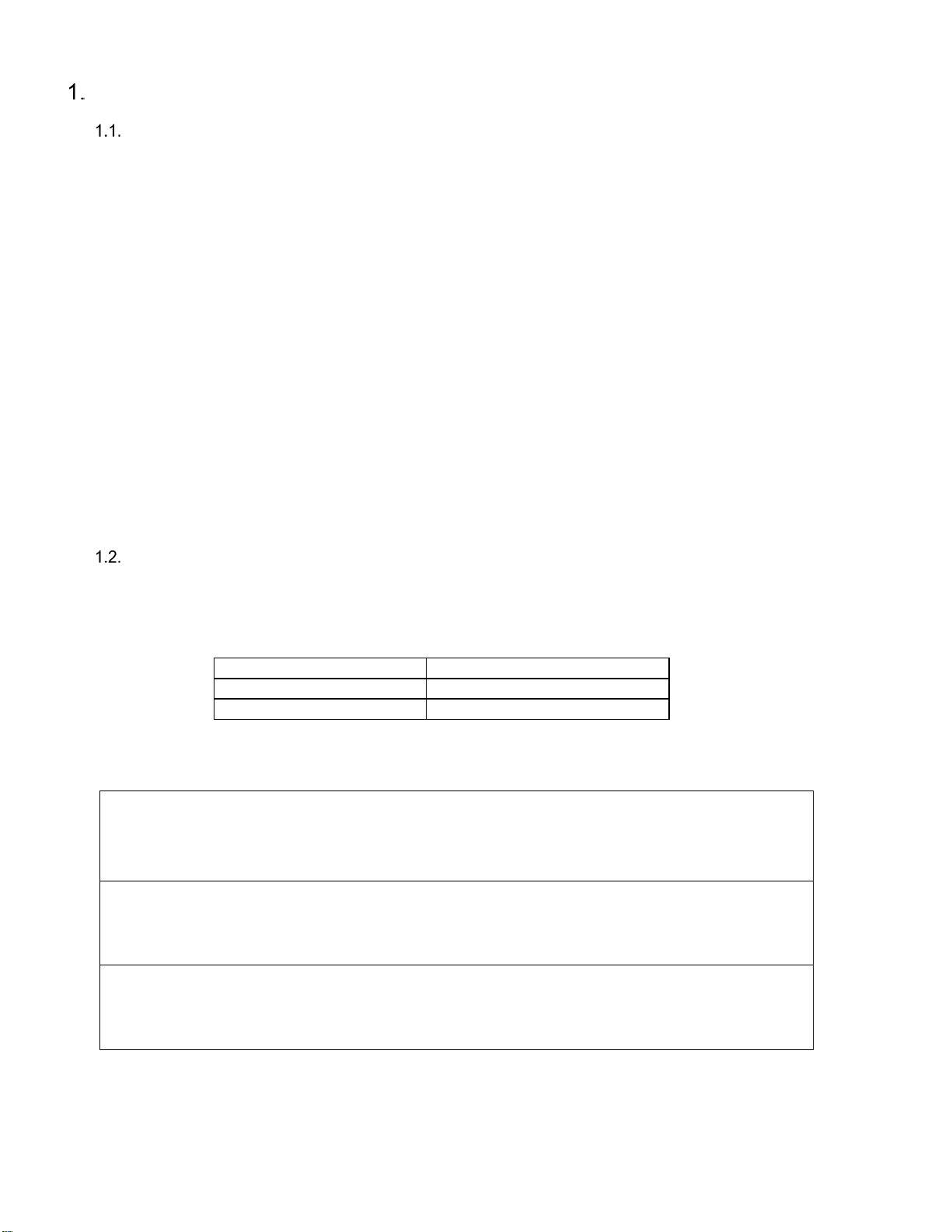

CE GAS TABLE

Refer to the following table for gas specifications for the country of use. If the country of use is NOT listed, refer

to the information printed on the data plate.

Belgium – Natural gas units require a restrictor orifice on the supply line for proper operation.

AT, BG, CH, CZ, DK, EE, FI, GB, GR, HR, HU, IE, IT, LT, LV,

NO, PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ESI

BE

I

2E+

NO

DE

I

2ELL

NL

G25-G25.3 I

2L

- I

2EK

25 2.60 mm 2.9/2.8

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HR, HU, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31 I

3P

23.9 37/50 37 .0625" LP16 YES 1.0

AT, BG, CH, CZ, DK, EE, FI, GB, GR, HR, HU, IE, IT, LT, LV,

NO, PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ESI

BE

I

2E+

NO

DE

I

2ELL

#42 / #37

NL

G25-G25.3 I

2L

- I

2EK

25 #37 3.5/3.4

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HR, HU, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31 I

3P

28.9 37/50 25.4 1.50 mm LP16 YES 1.2

AT, BG, CH, CZ, DK, EE, FI, GB, GR, HR, HU, IE, IT, LT, LV,

NO, PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ESI

BE

I

2E+

NO

DE

I

2ELL

NL

G25-G25.3 I

2L

- I

2EK

25 2.70 mm (#36) 4.0/3.9

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HR, HU, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31 I

3P

32.9 37/50 25.4 1.59 mm (.0625") LP16 YES 1.3

AT, BG, CH, CZ, DK, EE, FI, GB, GR, HR, HU, IE, IT, LT, LV,

NO, PL, PT, RO, ES, SI, SK, SE, TR

I

2H

LU

I

2E

FR

I

2ESI

BE

I

2E+

NO

DE

I

2ELL

NL

G25-G25.3 I

2L

- I

2EK

25 2.60 mm 4.4/4.3

BE, BG, CH, CZ, DE, ES, FR, GB, GR, HR, HU, IE, IS, IT, LT,

LU, LV, MK, MT, NL, PL, PT, RO, SI,

LP G31 I

3P

36.8 37/50 25.4 1.51 mm (#53) LP16 YES 1.5

10.8

YES

20/25 #38 / #36

31.4

20

20/25

32.2 10

YES

Pilot

Orifice (code)

YES

2.44 mm N22

N22

YES

YES

YES

G20/G25

G20

45AS 35.8

Applicable

Countries

20

20/25

Nominal Gas

Rate (m3/hr)

Model

Fuel Type

Net

Input (kW)

Supply

Pressure (mbar)

Burner

Pressure (mbar)

Burner

Orifice

70AS

35AS

40AS

Nat

Nat

Nat

Nat

Gas

Appliance

Category

Gross

Input (kW)

YES

2.58 mm

(#38)

20

28.3 10 N22

G20

G20/G25 26 23.4

N22

Governor

#42 3.0

3.0/3.5

2.5/2.9

2.5

3.4

3.4/4.0

3.8/4.4

3.8

G20/G25

G20

2.38 mm

2.38 / 2.60 mm

G20

G20/G25

YES

40 20/25

20

36.0 10

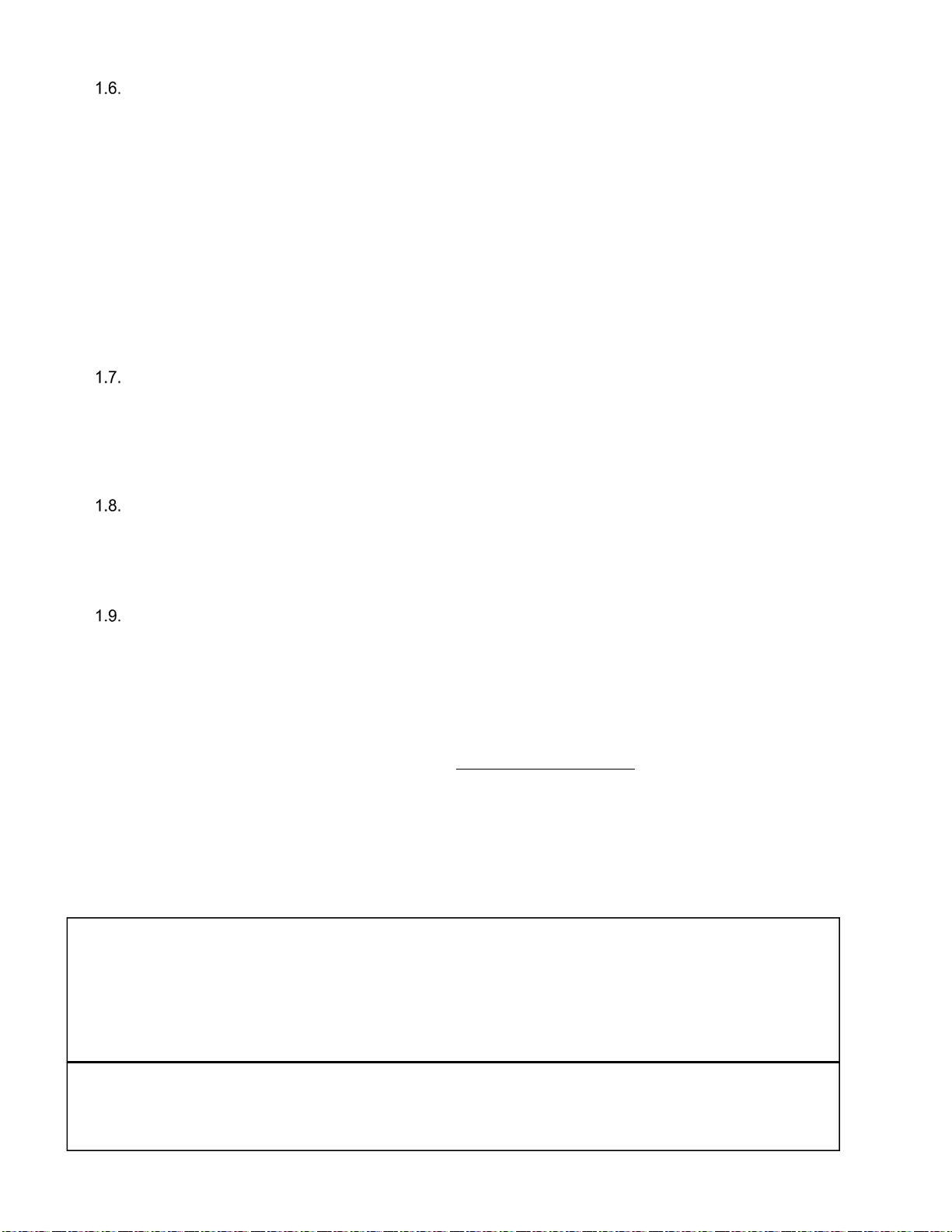

Natural 7" W.C. (17.4) 4" W.C. (10) #39 N22

Propane 11" W.C. (27.4) 10 W.C. (25) .0625" LP16

Natural 7" W.C. (17.4) 4" W.C. (10) #42 N22

Propane 11" W.C. (27.4) 10 W.C. (25) 1.5 mm LP16

Natural 7" W.C. (17.4) 4" W.C. (10) #38 N22

Propane 11" W.C. (27.4) 10 W.C. (25) #52 LP16

Natural 7" W.C. (17.4) 4" W.C. (10) #39 N22

Propane 11" W.C. (27.4) 10 W.C. (25) .0625" LP16

Natural 84 Mj/h 1.74 kPa 1.0 kPa 2.53 mm (#39) 0.56 mm (N22)

ULPG 86 Mj/h 2.74 kPa 2.5 kPa 1.59 mm (.0625") 0.41 mm (LP16)

Natural 102 Mj/h 1.74 kPa 1.0 kPa 2.37 mm (#42) 0.56 mm (N22)

ULPG 104 Mj/h 2.74 kPa 2.5 kPa 1.50 mm 0.41 mm (LP16)

Natural 116 Mj/h 1.74 kPa 1.0 kPa 2.58 mm (#38) 0.56 mm (N22)

ULPG 118 Mj/h 2.74 kPa 2.5 kPa 1.61 mm (#52) 0.41 mm (LP16)

Natural 130 Mj/h 1.74 kPa 1.0 kPa 2.38 mm (#42) 0.56 mm (N22)

ULPG 133 Mj/h 2.74 kPa 2.5 kPa 1.51 mm (#53) 0.41 mm (LP16)

70AS

NON CE

GAS TABLE

AUSTRALIAN

GAS TABLE

144 Mj/h

129 Mj/h

95 Mj/h

107,000 (31.3)

150,000 (44)

23.7

28.2

32.2

39.6

122,000 (35.8)

45AS

40AS

45AS

70AS

35AS

40AS 113 Mj/h

Burner

Pressure

(mbar)

Burner

Orifice

Pilot

Orifice

(code)

35AS

Model

Fuel Type

Gross

Input BTUs

(kW)

Net

Input BTUs

(kW)

Supply

Pressure

(mbar)

90,000 (26.3)