-

-

-

I

I

IN

N

ND

D

DE

E

EX

X

X

-

-

-

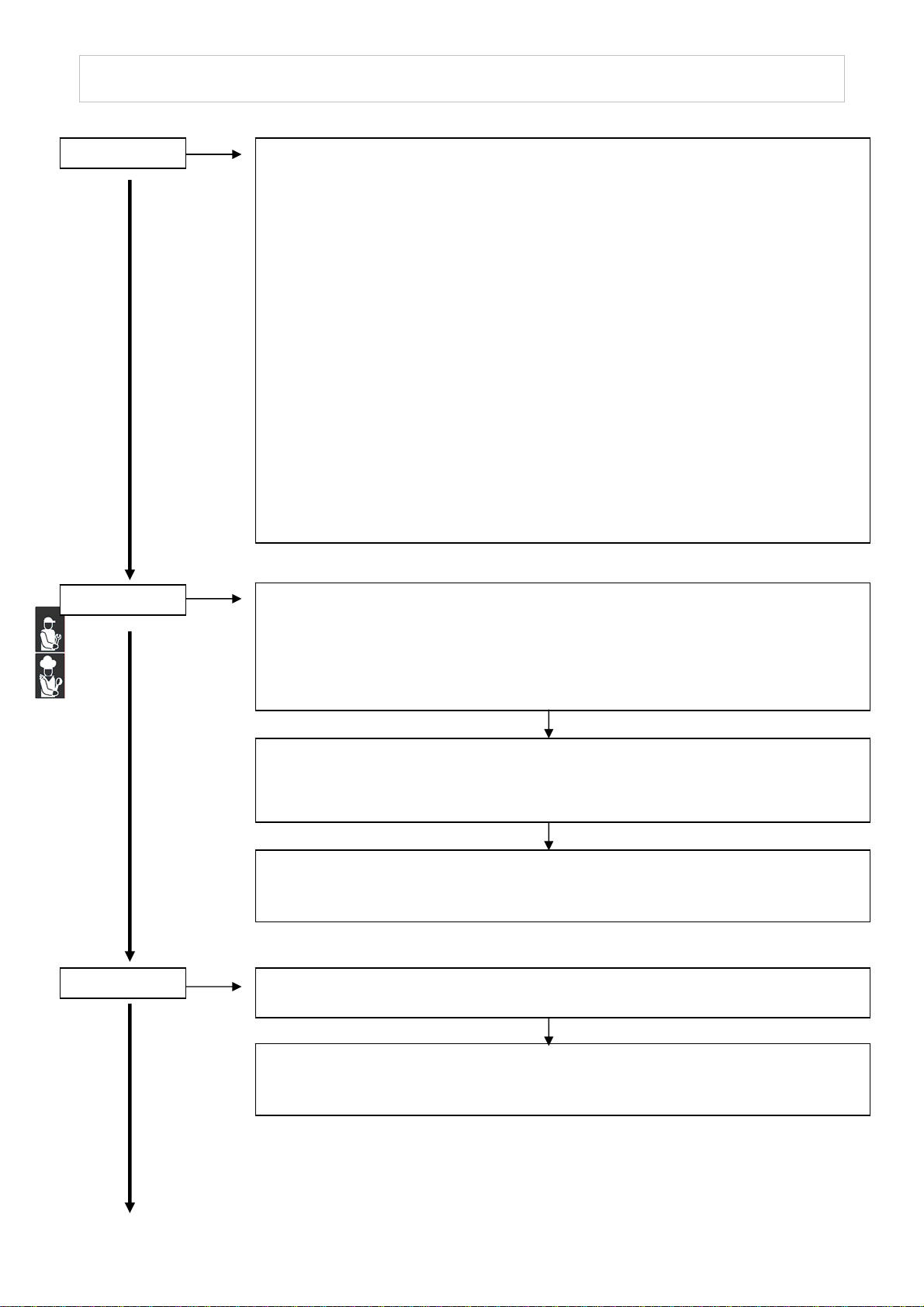

1st PART INSTRUCTION MANUAL …………………………………3

2st PART INSTALLATION MANUAL ………………………………27

0 INFORMATION FOR THE READER ………………………………………………3

1 GENERAL INSTRUCTIONS ON DELIVERY ……………………………………3

•GENERAL INSTRUCTIONS ……………………………………………………………………3

•TECHNICAL DATA ………………………………………………………………………………3

•LIST OF REGULATION REFERENCES ……………………………………………………3

•GENERAL INSTRUCTIONS ……………………………………………………………………3

•SETTING UP………………………………………………………………………………………4

•TESTING …………………………………………………………………………………………4

MACHINE LOADING …………………………………………………………………………………………………5

POSITION OF TRAYS ………………………………………………………………………………………………5

LENGTH ………………………………………………………………………………………………………………5

CORE PROBE ………………………………………………………………………………………………………6

2 CONTROL PANEL …………………………………………………………………7

•DESCRIPTION OF CONTROLS ………………………………………………………………7

3 OPERATION ..……………………….………………………………………………10

•PROGRAMS.…………………….………………………………………………………………10

IFR SLAUGHTERING CYCLE …………….………………………………………………………………………10

RECOMMENDED …………………………………………..………………………………………………………11

USER’S CYCLE …………………………………………….………………………………………………………11

Use User’s programmes ..……………………………………………………………………………………11

Memorise User’s programmes ..……………………………………………………………………………12

Cancel a User’s programmes ..………………………………………………………………………………13

Rename a User’s programmes ..……………………………………………………………………………13

PRE-COOLING CYCLE ……………………………………………………………………………………………14

•MANUAL CYCLES .…………….………………………………………………………………15

Negative slaughter cycle with core probe …………………………………………………………………16

Negative slaughter cycle with timer …………………………………………………………………………16

Soft positive slaughter cycle with core probe ………..……………………………………………………17

Soft positive slaughter cycle with time ……………….……………………………………………………18

Hard positive slaughter cycle with core probe ………….…………………………………………………18

Hard positive slaughter cycle with time ……………………………………………………………………19

•STORE …………………………...………………………………………………………………20

POSITIVE STORE ………………………….………………………………………………………………………20

NEGATIVE STORE ………………………………………..………………………………………………………20

•DEFROSTING ………………………….………………………………………………………22

•STERILIZATION …………………………….…………………………………………………22

•CLOCK SETTING ………………………………………………………………………………23

•LANGUAGE …..…………………………………………………………………………………23

•ALARM ………..…………………………………………………………………………………23

•SERVICE ……..…………………………………………………………………………………23

•INPUTS/OUTPUTS ..……………………………………………………………………………23

4 MAINTENANCE ……………………………………………………………………24

•MAINTENANCE AND CLEANING ……………………………………………………………24

CLEANING THE CABINET…………………………………………………………………………………………24

CLEANING THE AIR CONDENSER ……………………………………………………………………………25

STAINLESS-STEEL MAINTENANCE ……………………………………………………………………………25

DISCONTINUED USE ……………………………………………………………………………………………26