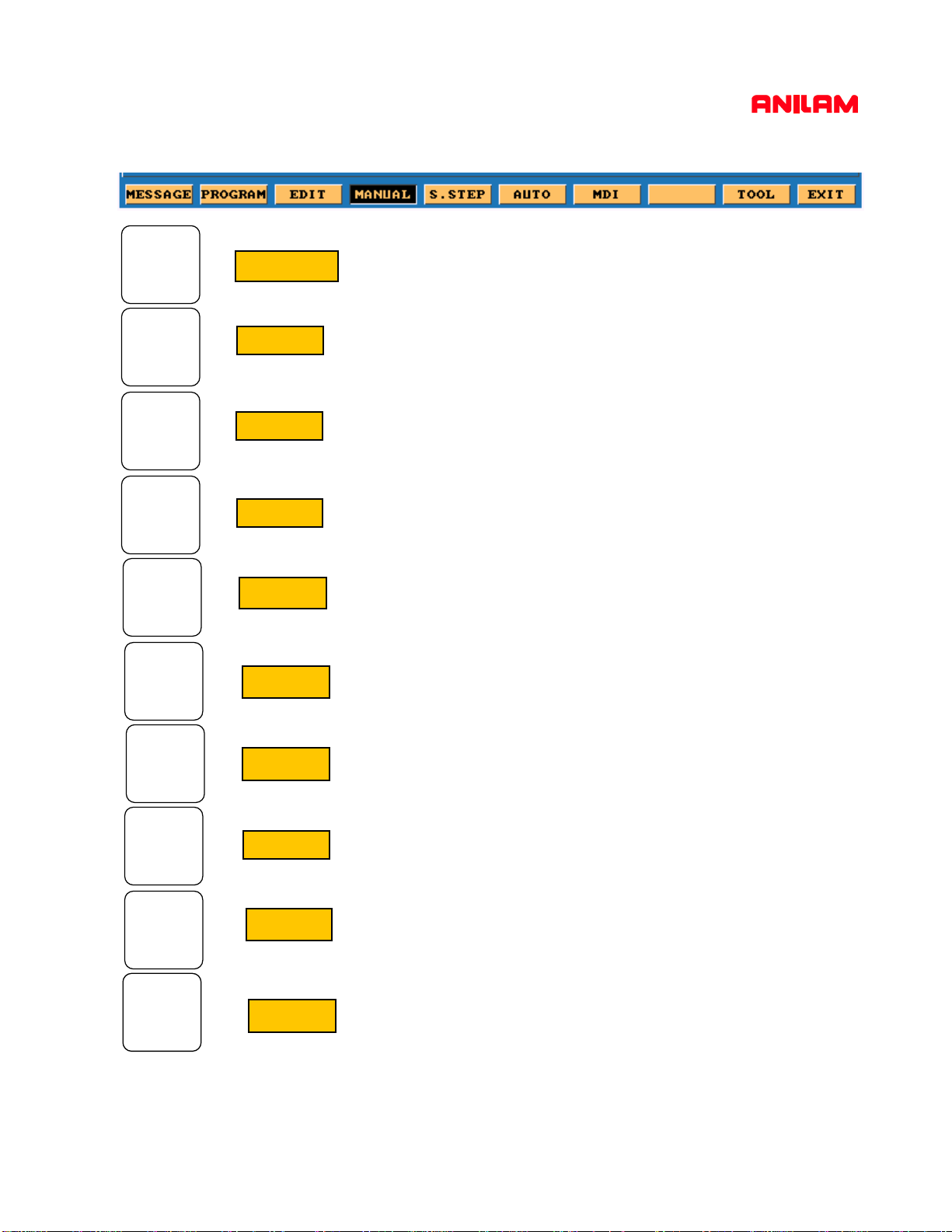

7

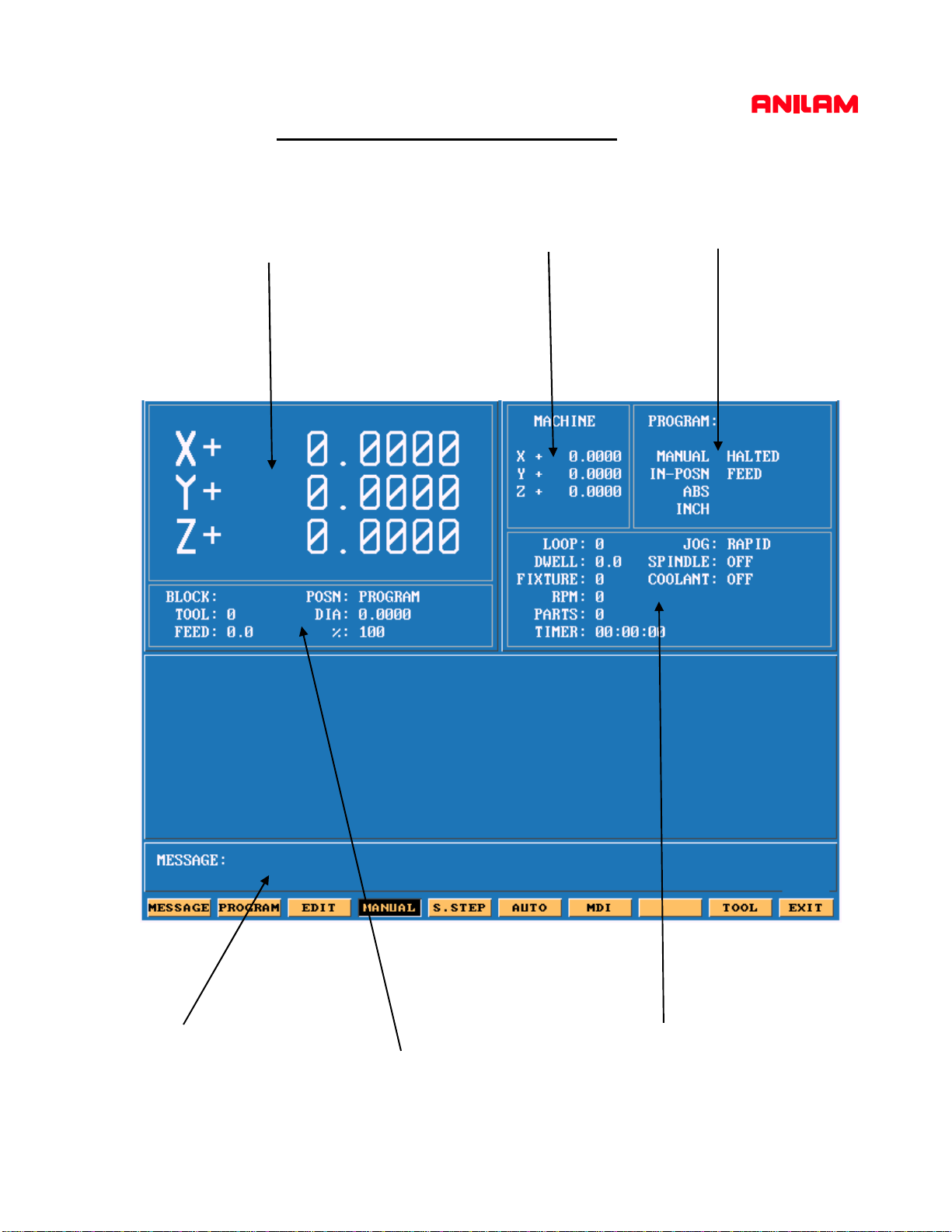

Display last 8 messages that have appeared

Page at which program files are displayed

Go to EDIT from Manual

Manual mode of operation

Single step mode of operation

Auto mode of operation

Manual data input,allow operation without writing a program

Not used

Tool page and Fixture offsets can also be acsessed from Edit

Exits control software

F1

F10

F2

F4

F5

F6

F7

F8

F9

F3

Message

Program

Edit

Manual

S.Step

Auto

M D I

Tool

Exit