1 - INTRODUCTION..............................................................................................1

2 - ABOUT ANKITS...............................................................................................2

3 - EQUIPMENT ...................................................................................................3

4 - TIPS AND SUGGESTIONS.................................................................................4

5 - SKILLS / PREREQUISITES .................................................................................5

5.1 HARDWARE/MECHANICAL................................................................................................... 5

5.2 WIRE –STRIPPING /TINNING................................................................................................ 6

5.3 OHM METER /RESISTORS ................................................................................................... 6

5.4 SOLDERING ...................................................................................................................... 6

5.5 CAPACITOR ORIENTATION .................................................................................................... 6

5.6 VOLTAGE CHECKS .............................................................................................................. 7

6 - DAC5.1 HISTORY & TECHNICAL OVERVIEW.....................................................8

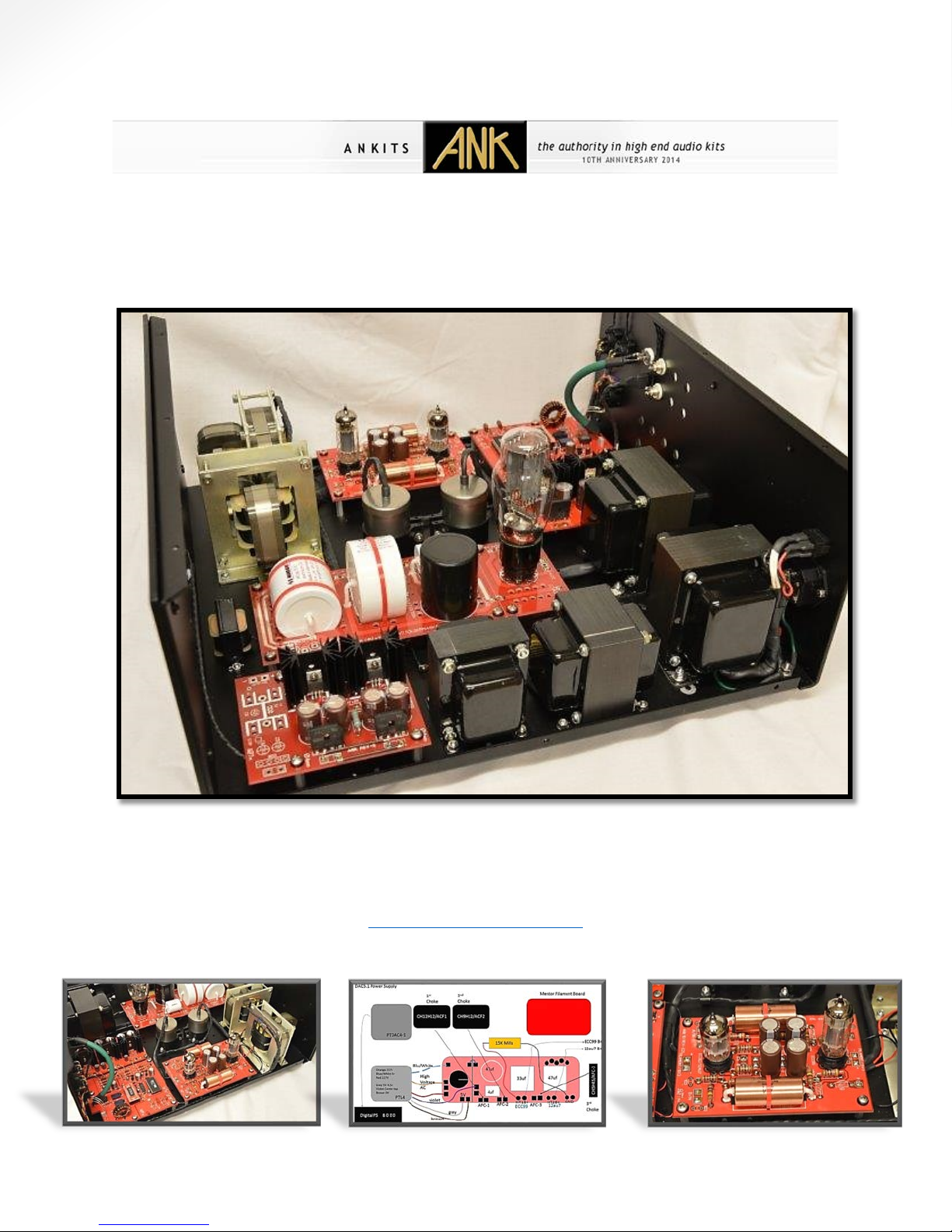

7 - DAC5.1 ASSEMBLY..........................................................................................9

7.1 INSTALL THE FEET............................................................................................................... 9

7.2 INSTALL THE DAC5.1 POWER SUPPLY.................................................................................... 10

7.3 INSTALL THE MAINS TRANSFORMERS .................................................................................... 12

7.3.1 Securing the PCB onto the chassis..............................................................................................................12

7.3.2 Connecting the White wires .......................................................................................................................13

7.3.3 Connecting the White/Grey wires..............................................................................................................14

7.3.4 Connecting the Black wires ........................................................................................................................15

7.3.5 Connecting the Black/Grey wires ...............................................................................................................16

7.3.6 Connecting the jumper cables 120V ONLY.................................................................................................17

7.3.7 Connecting the jumper cables 240V ONLY.................................................................................................18

7.3.8 Connecting the PCB to the Rocker switch ..................................................................................................19

7.3.9 Connecting the Rocker switch to the IEC....................................................................................................20

7.3.10 Connecting the IEC’s to the ground..........................................................................................................21

7.3.11 Final schematics of the 120V and 240V circuits .......................................................................................22

7.3.12 Mount the Mains Transformers into the chassis......................................................................................24

8 - FILAMENT BOARD ........................................................................................25

8.1 BUILDING THE FILAMENT BOARD ......................................................................................... 26

8.1.1 Mount the Filament board into the Chassis...............................................................................................28

8.2 POWER SUPPLY PCB ........................................................................................................ 29

8.2.1 Install a bridge ...........................................................................................................................................31

8.2.2 Install the 8-Pin Valve Base........................................................................................................................32

8.2.3 Install the White EVO Film Caps & the black 47uf TUBE cap .....................................................................33